Content Menu

● Introduction to Plastic Extrusion and German Engineering

● Key Features of German Plastic Extrusion Equipment

>> 1. Advanced Screw and Barrel Design

>> 2. High-Performance Drives and Motors

>> 3. Intelligent Control Systems

>> 4. Robust Downstream Equipment

>> 5. Modular and Customizable Design

● Mechanisms for Improving Production Efficiency

>> Continuous, High-Speed Production

>> Superior Material Utilization and Recycling

>> Enhanced Product Quality and Consistency

>> Rapid Setup and Changeovers

>> Integrated Quality Control

● Technological Innovations and Automation

>> Advanced Automation

>> Innovative Process Technologies

>> Custom Die and Tooling Solutions

● Energy Efficiency and Sustainability

>> Energy-Saving Drives and Heaters

>> Material Recycling and Waste Reduction

● Maintenance, Reliability, and Longevity

>> Durable Construction

>> Predictive and Preventive Maintenance

>> Global Support and Spare Parts Availability

● Case Studies and Real-World Applications

>> Film/Nonwoven Composites Without Adhesive

>> Direct Extrusion of Recyclate

>> Food-Safe Flat Film from PET Recyclate

>> High-Output Sheet Lines

● Conclusion

● FAQ

>> 1. What distinguishes German plastic extrusion equipment from other brands?

>> 2. How does automation in German extrusion lines improve production efficiency?

>> 3. Can German plastic extrusion equipment handle recycled materials?

>> 4. What maintenance practices are recommended for German plastic extrusion equipment?

>> 5. How do German extrusion lines contribute to sustainability?

● Citations:

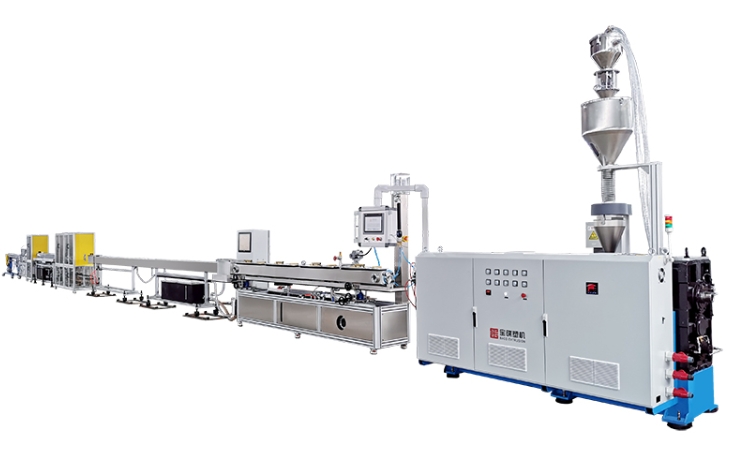

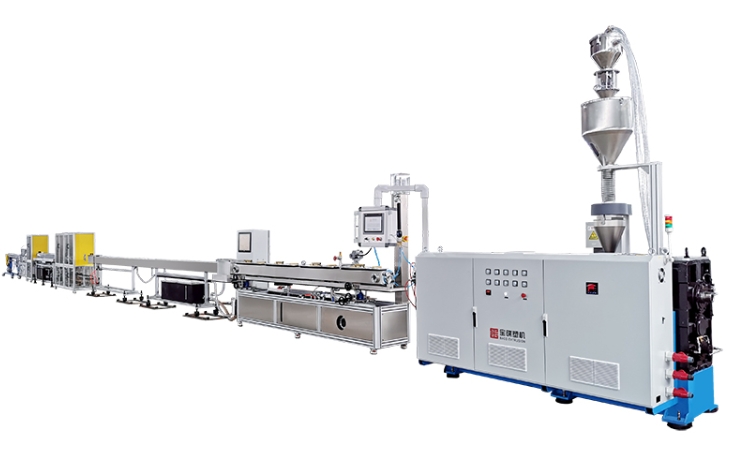

Plastic extrusion is a cornerstone technology in modern manufacturing, enabling the continuous production of high-quality plastic products ranging from films and sheets to pipes, profiles, and advanced composites. Among the global leaders in extrusion technology, German plastic extrusion equipment stands out for its precision engineering, innovation, and robust performance. But what exactly sets German-made extrusion lines apart, and how do they tangibly enhance production efficiency for manufacturers worldwide? This comprehensive article delves into the mechanisms, features, and industry practices that make German plastic extrusion equipment a benchmark for productivity and quality.

Introduction to Plastic Extrusion and German Engineering

Plastic extrusion is a continuous process in which raw plastic materials are melted and formed into a consistent profile through a die. The process is highly versatile, allowing for the production of a wide range of products with varying shapes, sizes, and properties[6].

German manufacturers have long been at the forefront of extrusion technology, leveraging their reputation for precision engineering, quality control, and innovation. German plastic extrusion equipment is synonymous with reliability, advanced automation, and adaptability to demanding industrial requirements[1][5][10].

Key Features of German Plastic Extrusion Equipment

1. Advanced Screw and Barrel Design

- German extruders typically employ meticulously engineered screws and barrels, often made from high-quality, hardened alloys for durability and wear resistance[1][5].

- The screw design is optimized for fast, gentle melting and thorough mixing, ensuring high melt quality and consistent output[1][13].

- Extended screw length-to-diameter ratios enhance plasticizing effects and allow for efficient processing of recycled materials and additives[5].

2. High-Performance Drives and Motors

- Direct drive systems and high-efficiency motors reduce energy loss and improve torque control, enabling higher output rates with lower energy consumption[1][3].

- Servo-controlled drives in downstream equipment ensure precise speed and tension control, crucial for maintaining product consistency[10].

3. Intelligent Control Systems

- Modern German extrusion lines are equipped with fully automated control systems, allowing real-time monitoring and adjustment of process parameters such as temperature, pressure, and screw speed[3][11].

- These systems minimize operator error, reduce setup times, and facilitate rapid product changeovers[11].

4. Robust Downstream Equipment

- German downstream equipment, including cooling baths, haul-offs, cutters, and winders, is designed for seamless integration and precise control, further enhancing overall line efficiency[10].

- Features such as automated cutting, pneumatic tension control, and customizable winding options streamline finishing processes[10].

5. Modular and Customizable Design

- German extrusion lines are highly modular, allowing manufacturers to tailor equipment configurations to specific production needs, whether for mono- or co-extrusion, different material types, or specialized profiles[1][10].

Mechanisms for Improving Production Efficiency

Continuous, High-Speed Production

- German plastic extrusion equipment is engineered for uninterrupted, high-speed operation, enabling large-scale production with minimal downtime[3][4][5].

- Output rates can reach up to 2000 kg/h, with some sheet lines producing over 7.5 tons of finished products per day[1][5].

Superior Material Utilization and Recycling

- Advanced feed zones and screw designs enable the processing of up to 100% recycled plastic, including PET flakes and rHDPE, without compromising product quality[1][11].

- Direct processing of production waste and PCR (post-consumer recycled) materials eliminates the need for energy-intensive regranulation, reducing both costs and environmental impact[11].

Enhanced Product Quality and Consistency

- Precise temperature and pressure control, along with optimized screw geometry, ensure uniform melting and mixing, resulting in products with consistent dimensions and properties[1][3][5].

- Automated thickness scanning and die adjustments further reduce variability and scrap rates[10][11].

Rapid Setup and Changeovers

- Automation systems such as Reifenhäuser's PAM (precise, autonomous, mechatronic) option allow for automatic, mechatronic adjustment of coextrusion adapters and flat dies, reducing setup times by up to 78% compared to manual methods[11].

- Recipe memories and guided start-up assistants help operators quickly switch between products, minimizing downtime and material waste[11].

Integrated Quality Control

- Vision inspection systems and high-precision sensors are increasingly standard in German extrusion lines, enabling real-time defect detection and immediate process correction[3][10].

- Automated handling and packaging further streamline post-extrusion processes, reducing labor requirements and potential for human error[3].

Technological Innovations and Automation

Advanced Automation

- German extrusion equipment is at the cutting edge of automation, incorporating programmable logic controllers (PLCs), touch-screen HMIs, and remote monitoring capabilities[3][11].

- Automation not only improves repeatability and product quality but also reduces the need for skilled labor and operator intervention[11].

Innovative Process Technologies

- Direct extrusion of recycled materials and fluff, as well as the elimination of pre-drying steps for PET recyclate, are unique process innovations pioneered by German manufacturers[11].

- Water shock cooling (EVO Aqua Cool) in blown film lines delivers higher cooling performance, increased transparency, and improved thermoforming properties compared to conventional air cooling[11].

Custom Die and Tooling Solutions

- German manufacturers excel in designing custom dies for complex profiles and multi-layer products, expanding the range of possible applications and product functionalities[3][10].

Energy Efficiency and Sustainability

Energy-Saving Drives and Heaters

- High-efficiency direct drives and advanced heating systems significantly reduce energy consumption, lowering operational costs and environmental footprint[1][3][4].

- Intelligent energy management systems further optimize power usage across the extrusion line[1].

Material Recycling and Waste Reduction

- The ability to process high levels of recycled content and re-extrude scrap material promotes a circular economy and minimizes landfill waste[1][4][11].

- Efficient material utilization and reduced scrap rates directly translate into cost savings and improved sustainability metrics[3][4].

Maintenance, Reliability, and Longevity

Durable Construction

- German extruders are built with premium materials and components, such as hardened screws and barrels, ensuring longevity and resistance to wear and corrosion[1][5][6].

- Modular assembly (e.g., latch-assembled racks and wallboards) enhances structural stability and simplifies maintenance[5].

Predictive and Preventive Maintenance

- Advanced diagnostics and maintenance scheduling features allow for proactive identification of wear and potential failures, reducing unplanned downtime[3][9].

- Regular cleaning, lubrication, and calibration are facilitated by user-friendly machine designs and accessible components[6][9].

Global Support and Spare Parts Availability

- German manufacturers typically offer fast, uncomplicated customer service and guaranteed spare parts availability worldwide, ensuring minimal disruption to production[10].

Case Studies and Real-World Applications

Film/Nonwoven Composites Without Adhesive

- Reifenhäuser's Ultrathin Coating process enables the production of lightweight, cost-effective film/nonwoven composites without hotmelt adhesives, reducing both costs and maintenance requirements[11].

Direct Extrusion of Recyclate

- The EVO Ultra Fusion process allows direct extrusion of fluff and PCR materials, bypassing the regranulation step and saving energy and time[11].

Food-Safe Flat Film from PET Recyclate

- Twin-screw technology enables the direct processing of PET recyclate into food-safe films without pre-drying, meeting stringent FDA and EFSA standards[11].

High-Output Sheet Lines

- German-designed hydraulic winding systems can handle rolls up to 1.5 tons, significantly reducing labor and operational costs compared to traditional methods[5].

Conclusion

German plastic extrusion equipment is a benchmark for efficiency, reliability, and innovation in the plastics manufacturing industry. Through advanced engineering, automation, and a focus on sustainability, German extrusion lines deliver higher output rates, superior product quality, and lower operational costs. Their ability to process recycled materials, minimize waste, and integrate seamlessly with downstream automation makes them indispensable for manufacturers seeking to optimize productivity and stay competitive in a rapidly evolving market. By investing in German plastic extrusion equipment, companies not only future-proof their operations but also contribute to a more sustainable and efficient industrial landscape.

FAQ

1. What distinguishes German plastic extrusion equipment from other brands?

German plastic extrusion equipment is renowned for its precision engineering, advanced automation, and robust construction. Features such as optimized screw and barrel designs, energy-efficient drives, and intelligent control systems set German machines apart, ensuring consistent product quality and high throughput[1][3][5].

2. How does automation in German extrusion lines improve production efficiency?

Automation enables real-time monitoring and adjustment of process parameters, rapid setup and changeovers, and integration with quality control systems. This reduces operator intervention, minimizes errors, and significantly shortens downtime during product transitions, thus boosting overall efficiency[3][11].

3. Can German plastic extrusion equipment handle recycled materials?

Yes, many German extrusion lines are specifically designed to process up to 100% recycled plastics, including PET flakes and rHDPE. Advanced feed zones and screw designs ensure gentle melting and thorough mixing, maintaining high product quality even with recycled content[1][11].

4. What maintenance practices are recommended for German plastic extrusion equipment?

Regular preventive maintenance—including cleaning, lubrication, inspection, and calibration—is essential. German machines often feature user-friendly designs and diagnostics to facilitate maintenance, and global support ensures quick access to spare parts and technical assistance[6][9][10].

5. How do German extrusion lines contribute to sustainability?

By enabling high levels of recycled content, minimizing energy consumption, and reducing material waste, German plastic extrusion equipment supports sustainable manufacturing practices. Innovations such as direct extrusion of recyclate and efficient cooling systems further lower the environmental impact[1][3][4][11].

Citations:

[1] https://diamat.com/components/extrusion/

[2] https://www.polytimetech.com/news/what-are-the-advantages-of-plastic-extruders-suzhou-polytime-machinery-co-ltd/

[3] https://jieyatwinscrew.com/blog/everything-you-need-to-know-about-plastic-extrusion-machines/

[4] https://www.plasticonline.com.au/versatile-world-of-plastic-extrusion/

[5] http://extruder-lines.com/1-plastic-sheet-extrusion-equipment.html

[6] https://jieyatwinscrew.com/blog/the-ultimate-guide-to-plastic-extruder-machines/

[7] https://abhiplastics.com/the-ultimate-guide-to-boosting-productivity-with-plastic-extrusion-machines/

[8] https://www.jwellmachine.com/analysis-and-solution-of-common-failures-of-plastic-extruder/

[9] https://www.linkedin.com/pulse/how-do-maintenance-plastic-extruders-farooq-rasheed-ansari-baba--xj7pf

[10] https://diamat.com/products/downstream/

[11] https://reifenhauser.com/en/company/media/news-and-stories/success-story/increase-productivity-plastics-extrusion

[12] https://jieyatwinscrew.com/blog/the-ultimate-guide-to-plastic-extrusion-and-choosing-the-right-extruder-machine/

[13] https://www.cowinextrusion.com/key-points-to-pay-attention-to-when-selecting-plastic-extruder/

[14] https://www.linkedin.com/pulse/common-problems-twin-screw-extrusion-equipment-echo-wang

[15] https://paretoplastic.com/top-plastic-extrusion-manufacturers-germany/

[16] https://www.gsextruder.com/top-10-plastic-sheet-extrusion-machine-manufacturers-in-2024/

[17] https://www.professionalsuk.co.uk/article/business-management/57169/german-plastic-extrusion-machine-industry-overview-market-drivers-2032

[18] https://www.hansweber.de/en/products-services/extrusion

[19] https://www.fangliextru.com/news-show-1069125.html

[20] https://dartplast.en.made-in-china.com/product/wsCmEerJrScd/China-German-Plastic-Extrusion-Machinery-with-Whole-Line-Price.html

[21] https://www.alibaba.com/showroom/german-extrusion-machinery.html

[22] https://www.rayda.co.uk/blog/advantages-and-disadvantages-of-plastic-extrusion/

[23] https://www.jwellmachine.com/analysis-of-plastic-extrusion-technology/

[24] https://www.aimprocessing.com/blog/the-benefits-of-plastic-injection-molding-compared-to-extrusion

[25] https://www.battenfeld-cincinnati.com

[26] https://www.troester.de/content/uploads/2022/05/Extr_Equipment_Cable_2020-03_web1.pdf

[27] https://www.twi-global.com/technical-knowledge/faqs/plastic-extrusion

[28] https://www.cowinextrusion.com/all-about-plastic-extrusion-and-helpful-tips-for-buying-extruder-machinery/

[29] https://www.blessonextrusion.com/faqs/

[30] https://www.recreuslab.com/newyork/latest-update/plastic-extrusion-machine-supplier-in-germany-we/36

[31] https://www.cowellextrusion.com/top-10-plastic-extrusion-machine-manufacturers/

[32] https://www.medicalextruders.com/info/extrusion-equipment-maintenance-method-24455647.html

[33] https://www.dwellextrusion.com/faq/

[34] https://www.plasticonline.com.au/versatile-world-of-plastic-extrusion/

[35] https://api.pageplace.de/preview/DT0400.9781569907764_A38515627/preview-9781569907764_A38515627.pdf

[36] https://www.jwellmachine.com/winter-maintenance-tips-for-plastic-extrusion-equipment/

[37] https://www.breyer-extr.com/en/