Content Menu

● Introduction to Aluminum Extrusion

>> The Extrusion Process

● Applications in Wisconsin

>> Industries Served

● Aluminum Extruders in Wisconsin

>> Key Players

● Customization and Finishing

>> Finishing Options

● Challenges and Innovations

>> Technological Advancements

● Conclusion

● FAQs

>> 1. What is the aluminum extrusion process?

>> 2. What industries use aluminum extrusions in Wisconsin?

>> 3. What are the common alloys used for aluminum extrusion?

>> 4. How are aluminum extrusions finished?

>> 5. What are the benefits of using aluminum extrusions?

● Citations:

Aluminum extrusion is a versatile manufacturing process used to create a wide range of products, from building frames to automotive parts. In Wisconsin, this process is particularly prominent due to the state's strong industrial base and the presence of numerous aluminum extruders. This article will delve into the intricacies of aluminum extrusion, its applications, and how it operates in Wisconsin.

Introduction to Aluminum Extrusion

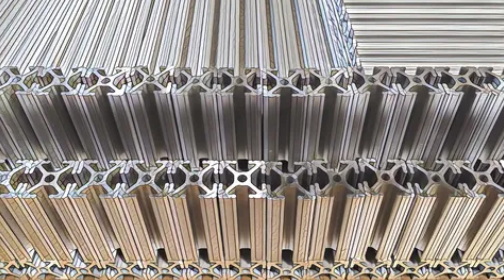

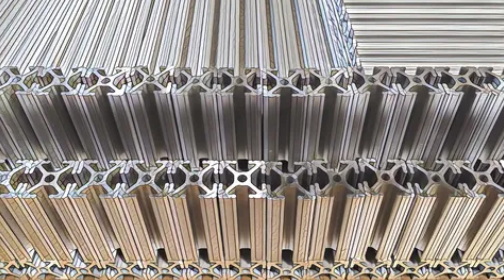

Aluminum extrusion involves forcing heated aluminum alloy through a die to create profiles with specific cross-sectional shapes. This process is highly efficient and allows for the production of complex shapes that would be difficult or impossible to achieve with other methods.

The Extrusion Process

The process begins with an aluminum billet, which is heated to make it malleable. The billet is then placed into an extrusion press, where a ram applies high pressure to push the aluminum through the die. The resulting extrusion takes the shape of the die and is cooled to solidify its new form.

Applications in Wisconsin

Wisconsin is home to a diverse range of industries that utilize aluminum extrusions, including construction, automotive, and electronics. Companies like Crystal Finishing Systems Inc. and Mid-States Aluminum Corp. are prominent players in the state's aluminum extrusion sector.

Industries Served

- Building & Construction: Aluminum extrusions are used for frames, windows, and doors due to their strength and light weight.

- Automotive & Electronics: Extrusions are used in vehicle components and electronic devices for their durability and corrosion resistance.

- Recreational & Marine: Used in boat frames and other marine equipment due to their resistance to corrosion.

Aluminum Extruders in Wisconsin

Several companies in Wisconsin specialize in aluminum extrusion, offering a range of services from custom extrusions to finishing and fabrication.

Key Players

- Crystal Finishing Systems Inc.: Offers ISO 9001 certified extrusion services with multiple presses across different locations.

- Mid-States Aluminum Corp.: Known for short lead times and consistent quality, with a focus on lean manufacturing processes.

- Hydro Extrusion: Provides standard and custom extrusions with advanced manufacturing capabilities.

Customization and Finishing

Aluminum extrusions can be customized to meet specific design requirements. Finishing processes such as anodizing, powder coating, and machining are commonly used to enhance the appearance and functionality of extruded products.

Finishing Options

- Anodizing: Increases corrosion resistance and provides a durable finish.

- Powder Coating: Offers a wide range of colors and textures.

- Machining: Allows for precise modifications to the extruded shape.

Challenges and Innovations

The aluminum extrusion industry in Wisconsin faces challenges such as maintaining quality standards and adapting to new technologies. Innovations in die design and extrusion techniques continue to improve efficiency and product quality.

Technological Advancements

- Advanced Die Design: Improves the precision and complexity of extruded shapes.

- Sustainable Practices: Focus on reducing energy consumption and waste in the extrusion process.

Conclusion

Aluminum extrusion in Wisconsin is a thriving industry, supported by a strong infrastructure and innovative manufacturing practices. Companies like Crystal Finishing Systems Inc. and Mid-States Aluminum Corp. are leading the way in providing high-quality extrusions for various industries. As technology continues to evolve, the future of aluminum extrusion looks promising, with potential for increased efficiency and sustainability.

FAQs

1. What is the aluminum extrusion process?

The aluminum extrusion process involves heating an aluminum billet and forcing it through a die to create a specific shape. The resulting extrusion is then cooled to solidify its form.

2. What industries use aluminum extrusions in Wisconsin?

Aluminum extrusions are used in several industries, including building and construction, automotive, electronics, and recreational and marine sectors.

3. What are the common alloys used for aluminum extrusion?

Common alloys include 6005, 6061, 6063, and 7075, each with different properties suitable for various applications.

4. How are aluminum extrusions finished?

Finishing processes include anodizing, powder coating, and machining to enhance appearance and functionality.

5. What are the benefits of using aluminum extrusions?

Benefits include high strength-to-weight ratio, corrosion resistance, and the ability to create complex shapes efficiently.

Citations:

[1] https://www.youtube.com/watch?v=ELgtjeJyFw8

[2] https://www.crystalfinishing.com/aluminum-extrusion/

[3] https://www.iqsdirectory.com/extruded-aluminum/wisconsin/

[4] https://www.youtube.com/watch?v=g3tyZITFbdE

[5] https://www.hydro.com/profiles/custom-aluminum-extrusions-in-wisconsin

[6] https://midstal.com/sft1242/aluminum_extrusion_process_overview.pdf

[7] https://aec.org/faqs

[8] https://qst-corp.com/2023/02/13/aluminum-extrusions/

[9] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[10] https://community.xometry.com/kb/articles/761-metal-extrusion-frequently-asked-questions

[11] https://aluminum-extrusions.net/category/wisconsin/

[12] https://qst-corp.com/category/aluminum-extrusion/

[13] https://www.hydro.com/profiles/aluminum-extrusions-manufacturer-in-wisconsin

[14] https://www.iqsdirectory.com/aluminum-extrusions/wisconsin/