Content Menu

● The Aluminum Extrusion Process

>> Step 1: Preheating

>> Step 2: Loading the Billet

>> Step 3: Extrusion

>> Step 4: Cooling and Stretching

>> Step 5: Cutting and Aging

● Aluminum Extrusion in Portland, Oregon

>> Hydro Extrusion Portland

>> Extrusion Press Capabilities in Portland

● Applications of Aluminum Extrusions in Portland

● Value-Added Services in Portland's Aluminum Extrusion Industry

>> Fabrication Services

>> Surface Finishing

● The Advantages of Aluminum Extrusions

● Innovation and Research in Portland's Aluminum Extrusion Industry

● The Future of Aluminum Extrusion in Portland, Oregon

● Conclusion

● Frequently Asked Questions

>> 1. What are the main industries served by aluminum extrusion in Portland, Oregon?

>> 2. How does the aluminum extrusion process in Portland ensure environmental sustainability?

>> 3. What are the size limitations for aluminum extrusions produced in Portland?

>> 4. How do Portland's aluminum extrusion companies ensure quality control?

>> 5. What custom design services are available for aluminum extrusions in Portland?

● Citations:

Aluminum extrusion is a vital manufacturing process that plays a significant role in various industries, from construction to automotive. In Portland, Oregon, this process has become particularly important, with several companies specializing in aluminum extrusion services. This article will delve into the intricacies of aluminum extrusion in Portland, Oregon, exploring the process, its applications, and the key players in the local industry.

The Aluminum Extrusion Process

Aluminum extrusion is a technique used to create objects of a fixed cross-sectional profile. The process involves pushing heated aluminum through a die with a specific cross-sectional shape[1]. In Portland, Oregon, this process is carried out with precision and expertise by various manufacturers.

Step 1: Preheating

The process begins with preheating aluminum billets to temperatures between 400 and 500 degrees Celsius[2]. This step is crucial as it makes the aluminum malleable enough for extrusion without liquefying it.

Step 2: Loading the Billet

Once heated, the billet is quickly transferred to the extrusion press to prevent heat loss. A release agent or lubricant is applied to the billet and extrusion ram to prevent them from sticking together[2].

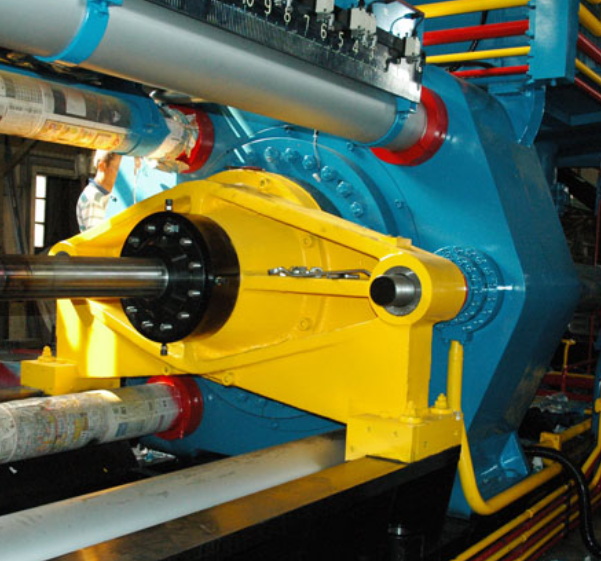

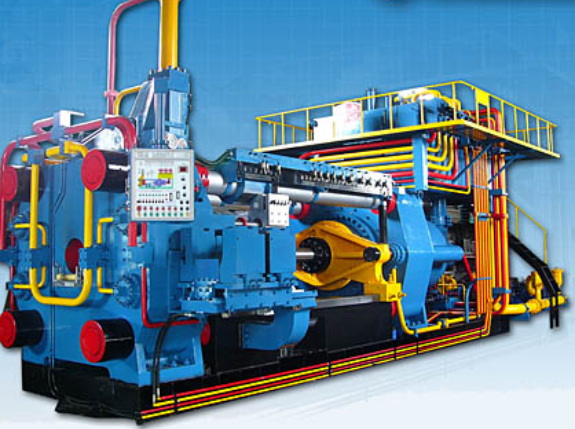

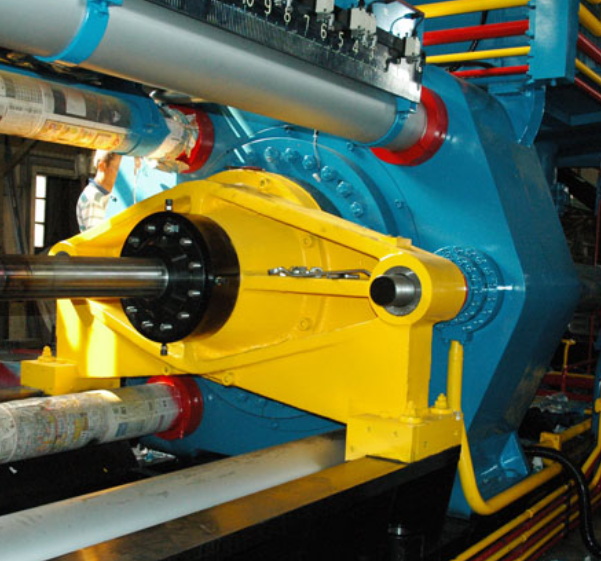

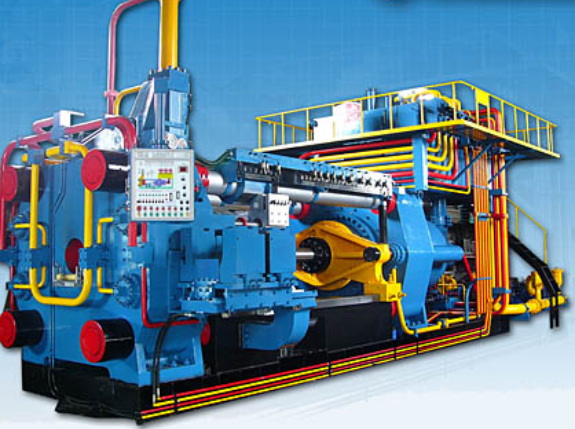

Step 3: Extrusion

In this critical step, a hydraulic ram applies immense pressure (up to 15,000 tons) to push the billet through the die[2]. The die, which can be customized to create various shapes, determines the final form of the extrusion.

Step 4: Cooling and Stretching

After extrusion, the aluminum is cooled through a process called quenching. The extruded piece is then stretched to straighten it and achieve the desired mechanical properties[2].

Step 5: Cutting and Aging

Finally, the extrusion is cut to the specified length and undergoes an aging process to enhance its strength and hardness[2].

Aluminum Extrusion in Portland, Oregon

Portland, Oregon, has established itself as a hub for aluminum extrusion, with several companies offering state-of-the-art services in this field.

Hydro Extrusion Portland

Hydro Extrusion's Portland facility is a prime example of the city's capabilities in aluminum extrusion. The facility is well-equipped with a technical design center and extensive fabrication capabilities[1]. It houses several extrusion presses of varying sizes, allowing for the production of a wide range of extrusion profiles.

Hydro Portland specializes in producing extruded aluminum for various industries, including aluminum curtainwall components for building and construction[7]. With in-house painting and anodizing capabilities, they supply aluminum to manufacturing companies throughout the Pacific Northwest and beyond.

Extrusion Press Capabilities in Portland

The extrusion presses in Portland's facilities are capable of producing a wide range of sizes and shapes. For instance, Hydro Extrusion's Portland facility boasts the following press sizes[1]:

- 550 ton (2.5"-4.5") (hard alloy and tight tolerances)

- 1,400 ton (5")

- 1,800 ton (7")

- 2,000 ton (7")

- 2,000 ton (8")

- 2,500 ton (9")

- 3,000 ton (10")

This variety allows for the production of extrusions ranging from small, intricate shapes to large, complex profiles.

Applications of Aluminum Extrusions in Portland

The versatility of aluminum extrusions makes them indispensable in various industries. In Portland, Oregon, these extrusions find applications in:

1. Construction: Aluminum extrusions are widely used in building facades, window frames, and structural components.

2. Transportation: The automotive and aerospace industries utilize aluminum extrusions for their lightweight and strength properties.

3. Consumer Goods: From furniture to electronics, aluminum extrusions are used in many everyday products.

4. Industrial Equipment: Many industrial machines and tools incorporate aluminum extrusions in their design.

Value-Added Services in Portland's Aluminum Extrusion Industry

Portland's aluminum extrusion companies offer more than just the basic extrusion process. Many provide value-added services that enhance the functionality and appearance of the extruded products.

Fabrication Services

Companies like Hydro Extrusion offer extensive fabrication capabilities. These include[1]:

- CNC machining

- MIG, TIG, and robotic welding

- Precision cutting

- Drilling

- Tapping

- Punching

These services allow for the production of fully finished components and assemblies, reducing costs and cycle times for customers.

Surface Finishing

Surface treatments are crucial for both aesthetic and functional purposes. In Portland, aluminum extrusion companies offer various finishing options, including:

1. Anodizing: This electrochemical process increases corrosion resistance and hardness while allowing for a range of color options[1].

2. Powder Coating: This finish provides a durable, attractive coating that's resistant to chipping, fading, and wear.

3. Painting: Custom paint finishes can be applied to meet specific color and appearance requirements.

The Advantages of Aluminum Extrusions

Aluminum extrusions produced in Portland, Oregon, offer numerous benefits that make them a preferred choice in many applications:

1. Lightweight: Aluminum weighs only about 30% as much as steel, copper, or brass[1].

2. Strength: Some aluminum alloys are as strong as medium-grade steel, with a higher strength-to-weight ratio[1].

3. Corrosion Resistance: The natural oxide layer that forms on aluminum provides protection against corrosion[1].

4. Conductivity: Aluminum efficiently conducts both heat and electricity[1].

5. Recyclability: Aluminum is 100% recyclable, making it an environmentally friendly choice[1].

Innovation and Research in Portland's Aluminum Extrusion Industry

Portland's aluminum extrusion industry is not just about production; it's also a hub for innovation and research. Companies like Hydro offer support from their global research and development teams for design and product development[7].

This focus on innovation helps in developing energy-efficient solutions that meet the growing demand for lightweight and reduced energy consumption products. The collaboration between industry and research institutions in Portland continues to push the boundaries of what's possible with aluminum extrusions.

The Future of Aluminum Extrusion in Portland, Oregon

As industries continue to seek lightweight, strong, and sustainable materials, the demand for aluminum extrusions is expected to grow. Portland, with its established expertise and advanced facilities, is well-positioned to meet this demand.

The future may see even more advanced alloys, more complex extrusion profiles, and further improvements in energy efficiency and sustainability in the extrusion process. As the industry evolves, Portland's aluminum extrusion companies are likely to remain at the forefront, driving innovation and meeting the changing needs of various sectors.

Conclusion

Aluminum extrusion in Portland, Oregon, is a sophisticated process that combines advanced technology with skilled craftsmanship. From the initial heating of the billet to the final finishing touches, every step is carried out with precision and care. The city's aluminum extrusion industry, led by companies like Hydro Extrusion, offers a wide range of capabilities, from basic extrusions to complex, custom-designed profiles with value-added services.

The versatility, strength, and sustainability of aluminum extrusions make them an ideal choice for numerous applications across various industries. As Portland continues to innovate and expand its capabilities in aluminum extrusion, it solidifies its position as a key player in this vital manufacturing sector.

Whether you're in construction, transportation, or any industry that requires high-quality, custom-designed aluminum components, Portland's aluminum extrusion industry offers the expertise, technology, and innovation to meet your needs.

Frequently Asked Questions

1. What are the main industries served by aluminum extrusion in Portland, Oregon?

The main industries served by aluminum extrusion in Portland, Oregon, include construction, transportation (automotive and aerospace), consumer goods, and industrial equipment manufacturing. Portland's extrusion companies provide custom solutions for a wide range of applications within these sectors.

2. How does the aluminum extrusion process in Portland ensure environmental sustainability?

Aluminum extrusion in Portland prioritizes environmental sustainability through several methods. Firstly, aluminum is 100% recyclable without losing its original qualities. Companies like Apex Aluminum Extrusions recycle all of their scrap aluminum[5]. Additionally, the extrusion process itself is relatively energy-efficient, and many Portland-based companies are continually working on improving their energy usage and reducing waste.

3. What are the size limitations for aluminum extrusions produced in Portland?

The size limitations for aluminum extrusions in Portland vary depending on the specific manufacturer and their equipment. For example, some facilities can produce extrusions with a weight-per-foot range of 0.033 to 10 pounds and a circle size up to 10+ inches[9]. However, it's best to consult with specific manufacturers for their exact capabilities.

4. How do Portland's aluminum extrusion companies ensure quality control?

Portland's aluminum extrusion companies employ rigorous quality control measures. For instance, they ensure fabricated parts meet required specifications through meticulous inspection, including creating custom gauging to ensure the fit and function of each part when necessary. Many companies, like Star Extrusions, maintain ISO 9001:2015 certifications across all of their manufacturing facilities[6].

5. What custom design services are available for aluminum extrusions in Portland?

Many Portland-based aluminum extrusion companies offer comprehensive custom design services. They can work with clients from the initial concept stage to the final product, utilizing computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies. Some companies, like Hydro, also offer support from their global research and development teams for design and product development[7].

Citations:

[1] https://www.hydro.com/profiles/custom-aluminum-extrusions-in-oregon

[2] https://www.pennex.com/press/the-steps-of-aluminum-extrusion

[3] https://aluminum-extrusions.net/sapa-inc/

[4] https://aec.org/faqs

[5] https://www.apexextrusions.ca/about-apex/faq/

[6] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq

[7] https://www.hydro.com/en/global/about-hydro/hydro-worldwide/americas/united-states/west/hydro-portland-or/

[8] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/

[9] https://starext.com/frequently-asked-questions-about-aluminum-extrusions