Content Menu

● Understanding Aluminum Extrusion

>> Benefits of Aluminum Extrusion in Product Design

● Applications of Aluminum Extrusion

>> Enhancing Product Design with Aluminum Extrusion

>>> 1. Customization

>>> 2. Integration of Features

>>> 3. Improved Performance

>>> 4. Enhanced Durability

>>> 5. Aesthetic Versatility

>> Innovations in Aluminum Extrusion Technology

>> Case Studies Highlighting Aluminum Extrusion Benefits

>>> Case Study 1: Automotive Industry

>>> Case Study 2: Architectural Applications

>>> Case Study 3: Consumer Electronics

● Future Trends in Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What is aluminum extrusion?

>> 2. What are the advantages of using aluminum in product design?

>> 3. In which industries is aluminum extrusion commonly used?

>> 4. Can aluminum extrusions be customized?

>> 5. How does aluminum contribute to sustainability?

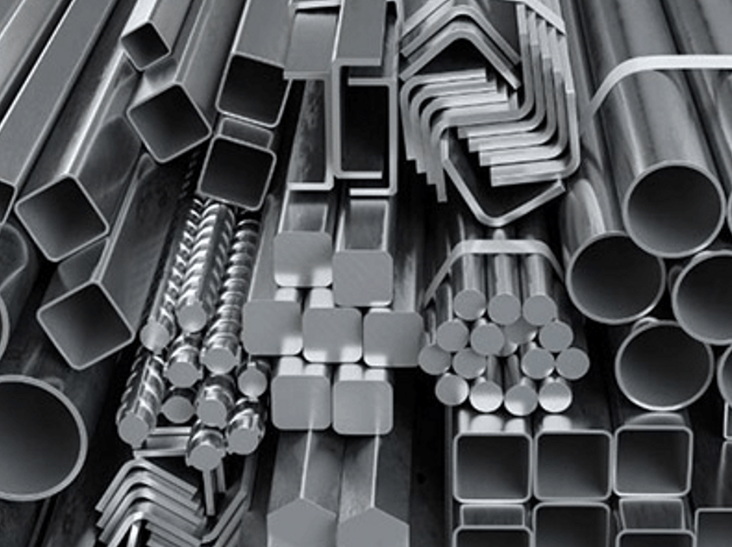

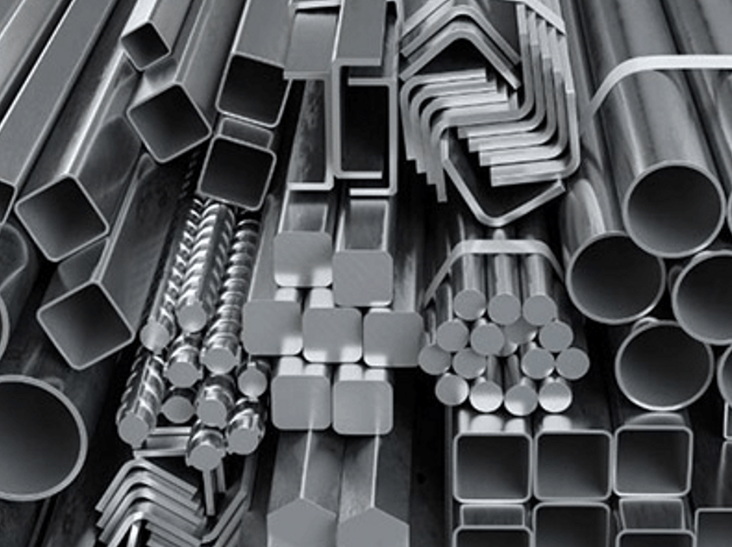

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into specific profiles by forcing it through a die. This technique has revolutionized product design across various industries, offering unique advantages that enhance functionality, aesthetics, and sustainability. In this article, we will explore how aluminum extrusion improves product design, its benefits, applications, and the future of this innovative process.

Understanding Aluminum Extrusion

Aluminum extrusion involves several key steps:

1. Material Selection: The process begins with selecting the appropriate aluminum alloy based on the desired properties of the final product.

2. Heating: The aluminum billets are heated to a specific temperature to make them malleable.

3. Extrusion: The heated billet is placed in an extrusion press, where it is forced through a die to create the desired shape.

4. Cooling: After extrusion, the profile is cooled, typically using air or water.

5. Cutting and Finishing: Finally, the extruded aluminum is cut to length and may undergo additional finishing processes such as anodizing or painting.

Benefits of Aluminum Extrusion in Product Design

Aluminum extrusion offers numerous advantages that significantly improve product design:

- Design Flexibility: The extrusion process allows for complex shapes and profiles that can be tailored to specific design requirements. Designers can create intricate designs that would be challenging or impossible with other manufacturing methods.

- Lightweight Yet Strong: Aluminum is known for its high strength-to-weight ratio. This characteristic enables designers to create lightweight products without compromising strength or durability.

- Cost-Effectiveness: Aluminum extrusion can reduce manufacturing costs due to its efficiency and the reduced need for secondary operations. This cost-effectiveness is particularly beneficial for large production runs.

- Sustainability: Aluminum is 100% recyclable without losing its properties. This makes aluminum extrusion an environmentally friendly choice for product design, aligning with modern sustainability goals.

- Aesthetic Appeal: The surface finish options available for extruded aluminum allow designers to achieve a wide range of aesthetic effects, enhancing the visual appeal of products.

Applications of Aluminum Extrusion

Aluminum extrusion is utilized in various industries due to its versatility:

- Construction: Used for window frames, door frames, and structural components due to its strength and resistance to corrosion.

- Automotive: Lightweight extruded components contribute to fuel efficiency while maintaining safety standards.

- Aerospace: The aerospace industry relies on aluminum extrusions for aircraft frames and components due to their lightweight and strength properties.

- Consumer Electronics: Many electronic devices use aluminum extrusions for housings and frames, providing durability while maintaining a sleek appearance.

- Furniture: Modern furniture designs often incorporate aluminum extrusions for their contemporary look and structural integrity.

Enhancing Product Design with Aluminum Extrusion

The integration of aluminum extrusion into product design can lead to innovative solutions that meet consumer demands effectively. Here are some ways aluminum extrusion enhances product design:

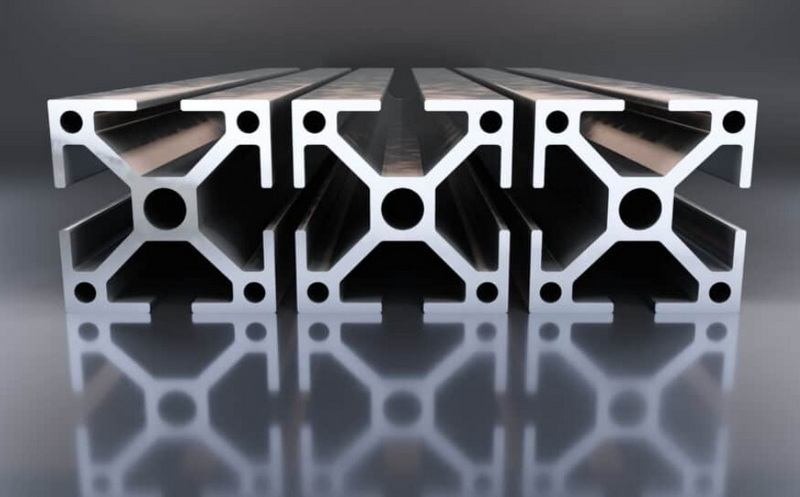

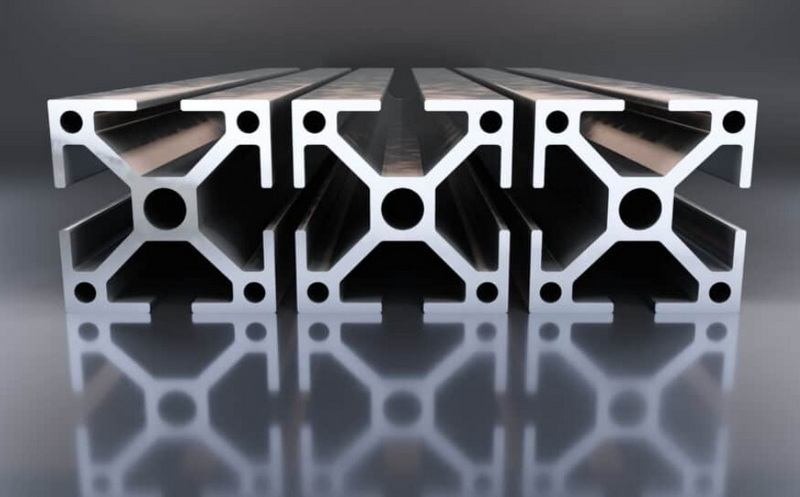

1. Customization

Aluminum extrusion allows for extensive customization options. Designers can specify exact dimensions, shapes, and finishes tailored to their products' needs. This level of customization enables brands to differentiate themselves in competitive markets.

2. Integration of Features

Extruded aluminum profiles can be designed with integrated features such as channels for wiring or grooves for mounting hardware. This integration simplifies assembly processes and reduces the number of components required in a product, streamlining production.

3. Improved Performance

The lightweight nature of aluminum contributes to improved performance in various applications. For instance, in automotive design, lighter vehicles lead to better fuel efficiency without sacrificing safety or performance standards.

4. Enhanced Durability

Aluminum's natural resistance to corrosion ensures that products maintain their appearance and functionality over time. This durability is particularly important in outdoor applications where exposure to elements can degrade materials quickly.

5. Aesthetic Versatility

With various finishing options available—such as anodizing, powder coating, or painting—aluminum extrusions can achieve different looks that appeal to consumers. This versatility allows designers to create visually striking products that align with current trends.

Innovations in Aluminum Extrusion Technology

As industries evolve, so does the technology surrounding aluminum extrusion:

- Advanced Die Design: Innovations in die technology allow manufacturers to create more complex shapes efficiently. These advanced dies reduce material waste and improve dimensional accuracy.

- Computer-Aided Design (CAD): The use of CAD software has streamlined the design process for aluminum extrusions. Designers can visualize their ideas in 3D before production begins, allowing for adjustments that enhance functionality and aesthetics.

- Automated Systems: Automation in the extrusion process increases production speed while maintaining quality control. Automated systems can monitor parameters such as temperature and pressure in real-time, ensuring consistent results.

Case Studies Highlighting Aluminum Extrusion Benefits

To illustrate the impact of aluminum extrusion on product design further, let's examine a few case studies from different industries:

Case Study 1: Automotive Industry

In the automotive sector, manufacturers have adopted aluminum extrusions extensively for vehicle frames and body panels. For example, a leading car manufacturer redesigned its sedan model using extruded aluminum components instead of traditional steel parts.

This change resulted in a weight reduction of approximately 20%, leading to improved fuel efficiency by nearly 15%. Additionally, the use of aluminum allowed for more innovative designs with better crash performance due to its energy absorption capabilities during impacts.

Case Study 2: Architectural Applications

In architecture, an innovative building project utilized custom-designed aluminum extrusions for its façade system. The architects aimed for a modern aesthetic while ensuring energy efficiency through thermal breaks within the profiles.

The result was not only visually stunning but also functional; the building achieved significant energy savings due to reduced heat transfer through the façade system. This project exemplifies how aluminum extrusion can enhance both form and function in architectural design.

Case Study 3: Consumer Electronics

A tech company decided to use aluminum extrusions for its latest line of laptops instead of plastic casings. The result was a sleek and robust design that appealed to consumers looking for premium products.

The use of extruded aluminum not only improved durability but also allowed for better heat dissipation during operation—an essential factor in maintaining performance levels in high-end electronics.

Future Trends in Aluminum Extrusion

As technology advances, so does the potential for aluminum extrusion in product design:

- 3D Printing Integration: The combination of aluminum extrusion with 3D printing technology may lead to new possibilities in creating complex geometries that were previously unattainable. Hybrid manufacturing techniques could allow designers to leverage both methods' strengths—creating intricate designs while maintaining structural integrity through extrusion.

- Smart Manufacturing: Implementing smart technologies in the extrusion process can optimize production efficiency and quality control, leading to better end products. IoT devices may monitor machinery performance continuously, predicting maintenance needs before failures occur.

- Sustainable Practices: As industries continue focusing on sustainability, innovations in recycling processes and eco-friendly finishes will likely become more prevalent in aluminum extrusion. Companies are exploring closed-loop systems where scrap material from production is reused directly in new extrusions.

Conclusion

Aluminum extrusion significantly enhances product design by offering flexibility, strength, cost-effectiveness, sustainability, and aesthetic appeal. Its applications span multiple industries, making it a vital component in modern manufacturing processes. As technology evolves, the future of aluminum extrusion looks promising, paving the way for even more innovative designs that meet consumer needs while adhering to sustainability principles.

FAQ

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into specific profiles by forcing it through a die under high pressure.

2. What are the advantages of using aluminum in product design?

The advantages include lightweight yet strong materials, design flexibility for complex shapes, cost-effectiveness in production, sustainability due to recyclability, and aesthetic versatility with various finishing options.

3. In which industries is aluminum extrusion commonly used?

Common industries include construction (for window frames), automotive (for lightweight components), aerospace (for aircraft structures), consumer electronics (for device housings), and furniture (for modern designs).

4. Can aluminum extrusions be customized?

Yes! Aluminum extrusions can be extensively customized regarding dimensions, shapes, and finishes tailored specifically to meet product requirements.

5. How does aluminum contribute to sustainability?

Aluminum is 100% recyclable without losing its properties, making it an environmentally friendly choice for manufacturers aiming for sustainable practices.