Content Menu

● Understanding Aluminum Extrusion

>> The Process of Aluminum Extrusion

● Benefits of Aluminum Extrusion in Glass Frames

>> 1. Strength and Lightweight Design

>> 2. Corrosion Resistance

>> 3. Thermal Efficiency

>> 4. Customizability

>> 5. Low Maintenance Requirements

● Applications of Aluminum Extrusion in Glass Framing

● Case Studies Highlighting Durability

● Future Trends in Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What are the primary benefits of using aluminum extrusions for glass frames?

>> 2. How does thermal efficiency impact energy costs?

>> 3. Can aluminum frames support large glass panels?

>> 4. What types of finishes can be applied to aluminum frames?

>> 5. Are there any environmental benefits associated with aluminum framing?

● Citations:

Aluminum extrusion has revolutionized the construction and design of glass frames, providing a multitude of benefits that enhance durability, aesthetics, and functionality. This article delves into how aluminum extrusion contributes to the longevity and resilience of glass frames, exploring its properties, manufacturing processes, and practical applications.

Understanding Aluminum Extrusion

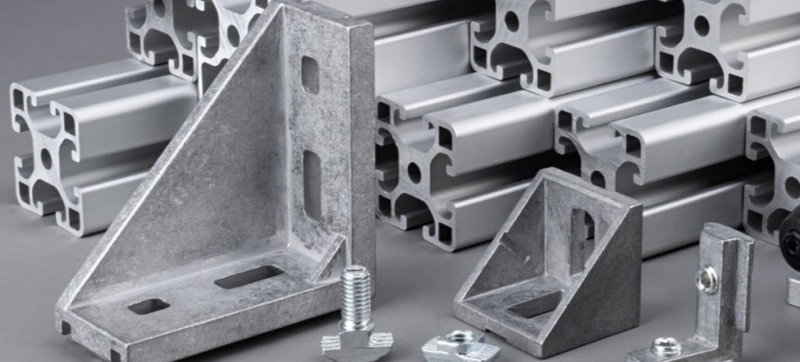

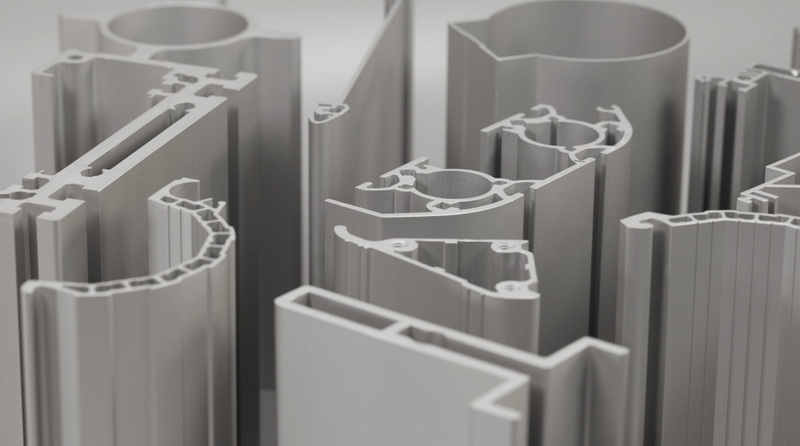

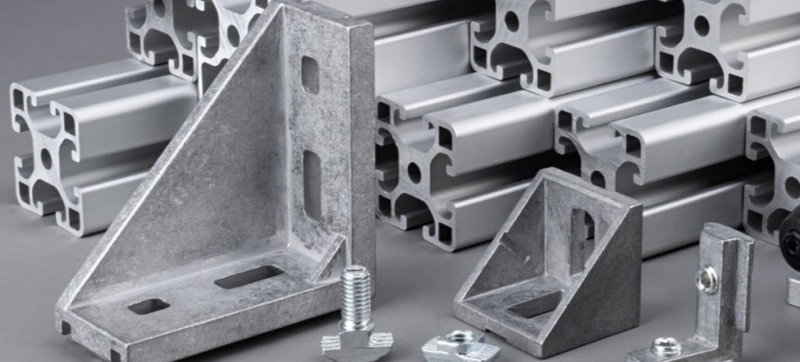

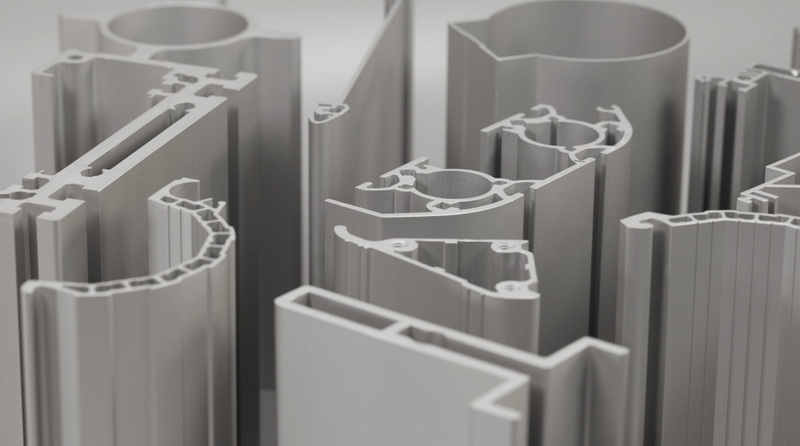

Aluminum extrusion is a manufacturing process that involves forcing aluminum alloy through a shaped die to create specific cross-sectional profiles. This technique allows for the production of complex shapes that are both lightweight and strong, making it an ideal choice for various applications, including glass framing.

The Process of Aluminum Extrusion

1. Material Selection: The process begins with selecting the appropriate aluminum alloy based on the desired properties such as strength, corrosion resistance, and thermal conductivity.

2. Heating: The aluminum is heated to a malleable state, allowing it to be easily shaped during the extrusion process.

3. Extrusion: The heated aluminum is pushed through a die to form the desired shape. This can include profiles designed specifically for glass frames.

4. Cooling and Finishing: Once extruded, the aluminum is cooled and can undergo various finishing processes such as anodizing or powder coating to enhance its properties.

Benefits of Aluminum Extrusion in Glass Frames

Aluminum extrusion offers several advantages that significantly improve the durability of glass frames:

1. Strength and Lightweight Design

Aluminum has an excellent strength-to-weight ratio, making it both strong and lightweight. This characteristic allows for larger glass panels without compromising structural integrity. The extruded profiles can support significant weight while remaining easy to handle and install.

The strength provided by aluminum extrusions is particularly important in high-rise buildings where large spans of glass are required. These frames can withstand wind loads and other environmental stresses without bending or warping over time.

2. Corrosion Resistance

One of the standout features of aluminum is its natural resistance to corrosion. Unlike steel, which can rust when exposed to moisture, aluminum forms a protective oxide layer that prevents degradation. This property is particularly beneficial for glass frames used in coastal areas or regions with high humidity.

Moreover, the ability to withstand harsh weather conditions means that aluminum frames maintain their structural integrity over time, reducing the need for frequent replacements or repairs.

3. Thermal Efficiency

Modern aluminum frames often incorporate thermal breaks—insulating materials placed between the interior and exterior surfaces of the frame. This design minimizes heat transfer, enhancing energy efficiency by keeping indoor temperatures stable. As a result, homes and buildings can reduce heating and cooling costs while maintaining comfort.

In addition to thermal breaks, many manufacturers are now employing advanced glazing techniques that work synergistically with aluminum frames to further improve energy efficiency. Low-emissivity (Low-E) coatings on glass can reflect heat back into the room during winter while keeping it out during summer, complementing the thermal performance of aluminum framing systems.

4. Customizability

The extrusion process allows for extensive customization of aluminum profiles. Manufacturers can create unique shapes and sizes tailored to specific design requirements. This flexibility enables architects and builders to achieve aesthetic goals without sacrificing performance.

Custom profiles can also accommodate various types of glazing systems, from single-pane to triple-pane insulated glass units. This adaptability ensures that designers can meet specific energy performance ratings while still achieving their desired architectural vision.

5. Low Maintenance Requirements

Aluminum frames require minimal maintenance compared to other materials like wood or steel. They do not need regular painting or treatment against rot or rust; a simple wash with soap and water is often sufficient to keep them looking new.

Furthermore, advancements in surface treatments such as anodizing or powder coating enhance not only aesthetics but also durability against scratches and fading due to UV exposure.

Applications of Aluminum Extrusion in Glass Framing

Aluminum extrusion is widely used in various applications involving glass frames:

- Residential Windows: Many modern homes utilize aluminum-framed windows due to their durability and energy efficiency.

- Commercial Buildings: Large glass facades in commercial buildings often employ aluminum extrusions for structural support while providing an attractive appearance.

- Curtain Walls: These systems use aluminum framing to support large glass panels in high-rise buildings, combining aesthetics with structural performance.

- Skylights: Aluminum extrusions are commonly used in skylight designs due to their ability to withstand outdoor elements while providing natural light.

- Glass Railings: In modern architecture, glass railings supported by aluminum extrusions provide safety without obstructing views, making them popular in both residential and commercial settings.

Case Studies Highlighting Durability

Several case studies illustrate how aluminum extrusion has improved durability in real-world applications:

1. The Burj Khalifa: As one of the tallest buildings in the world, the Burj Khalifa employs extensive use of aluminum framing for its curtain wall system. The choice of aluminum was crucial not only for its lightweight properties but also for its ability to withstand extreme wind loads at high altitudes.

2. The Sydney Opera House: Featuring large expanses of glass framed with custom-designed aluminum extrusions, this iconic structure benefits from enhanced durability against coastal weather conditions while maintaining its stunning aesthetic appeal.

3. Residential Developments: Numerous residential projects have adopted aluminum-framed windows due to their low maintenance needs and energy efficiency ratings, resulting in lower utility bills for homeowners over time.

Future Trends in Aluminum Extrusion

As technology continues to evolve, several trends are emerging within the field of aluminum extrusion that will further enhance its application in glass framing:

- Smart Technology Integration: The incorporation of smart technologies into window systems is on the rise. Sensors that monitor temperature changes or adjust tinting based on sunlight exposure are being integrated into aluminum-framed windows for improved energy management.

- Sustainability Practices: With increasing emphasis on sustainability, manufacturers are focusing on recycling processes for aluminum production and developing eco-friendly finishes that reduce environmental impact without compromising quality.

- Advanced Coatings: Innovations in coatings will lead to even greater resistance against scratches, UV damage, and chemical exposure—further extending the life cycle of aluminum frames used in various applications.

Conclusion

In conclusion, aluminum extrusion significantly enhances the durability of glass frames through its strength, corrosion resistance, thermal efficiency, customizability, and low maintenance needs. As building designs continue to evolve towards more sustainable and efficient solutions, the role of aluminum extrusion will only grow more critical in ensuring that structures are not only aesthetically pleasing but also resilient against environmental challenges.

FAQ

1. What are the primary benefits of using aluminum extrusions for glass frames?

Aluminum extrusions provide strength without added weight, excellent corrosion resistance, thermal efficiency through insulation features, customizability for design flexibility, and low maintenance requirements compared to other materials.

2. How does thermal efficiency impact energy costs?

Thermal efficiency reduces heat transfer between indoor and outdoor environments, helping maintain stable indoor temperatures which can lower heating and cooling costs over time.

3. Can aluminum frames support large glass panels?

Yes! Due to their high strength-to-weight ratio, aluminum frames can support larger glass panels without bending or warping over time.

4. What types of finishes can be applied to aluminum frames?

Common finishes include anodizing for corrosion resistance and aesthetic appeal as well as powder coating for additional color options and surface protection.

5. Are there any environmental benefits associated with aluminum framing?

Yes! Aluminum is recyclable and requires less maintenance over its lifespan compared to other materials like wood or steel, making it an eco-friendly choice for construction projects.

Citations:

[1] https://www.shenghai-alu.com/article/aluminum-profile-frame-can-bring-you-more-value.121

[2] https://www.otalum.com/advantages-of-using-aluminium-window-extrusion-profiles-in-construction.html

[3] https://exlabesa.com/uk/2023/05/19/is-extruded-aluminum-stronger-than-steel/

[4] https://www.istockphoto.com/photos/aluminum-window

[5] https://www.youtube.com/watch?v=2ASqovfuTTg

[6] https://hitopindustrial.com/aluminum-extrusion-process/

[7] https://stavianmetal.com/en/aluminum-framing/

[8] https://leadrp.net/blog/a-complete-guide-to-aluminum-extrusion/

[9] https://www.youtube.com/watch?v=ezuXdWRuGZc

[10] https://www.chaluminium.com/aluminum-frame-for-glass-panel-where-function-meets-form