Content Menu

● Understanding Aluminum Extrusion

● Benefits of Aluminum Extrusion for Automation

● Applications of Aluminum Extrusion in Automation

● How Automation Enhances Aluminum Extrusion Processes

● Advantages of Automated Material Handling

● Visualizing the Process

● Case Studies

● Expanding Applications of Aluminum Extrusions

● Future Trends in Aluminum Extrusion Automation

● Conclusion

● FAQ

>> 1. What is aluminum extrusion?

>> 2. How does aluminum extrusion improve automation efficiency?

>> 3. What industries benefit from aluminum extrusion?

>> 4. Can aluminum extrusions be customized?

>> 5. What are some common applications of aluminum extrusions in automation?

● Citations:

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into specific profiles by forcing it through a die. This technique has gained significant traction in various industries, particularly in automation, due to its efficiency and versatility. The integration of aluminum extrusion in automated systems enhances production capabilities, reduces costs, and improves product quality. In this article, we will explore how aluminum extrusion improves automation efficiency, the benefits it offers, and its applications across different sectors.

Understanding Aluminum Extrusion

Aluminum extrusion involves heating an aluminum billet to a malleable state and then pushing it through a die using a hydraulic press. The process can be broken down into several steps:

1. Preheating the Billet: The aluminum is heated to approximately 900°F (482°C) to make it malleable.

2. Extruding Through the Die: A hydraulic ram pushes the heated aluminum through the die, forming it into the desired shape.

3. Cooling and Cutting: Once extruded, the aluminum is cooled and cut to specified lengths.

This method allows for the creation of complex shapes that are lightweight yet strong, making aluminum extrusions ideal for various applications in automation.

Benefits of Aluminum Extrusion for Automation

Aluminum extrusion offers numerous advantages that significantly enhance automation efficiency:

1. Design Flexibility

One of the primary benefits of aluminum extrusion is its design flexibility. Engineers can create intricate shapes and profiles tailored to specific needs, which is crucial in automated systems where components must fit precisely within existing frameworks.

2. Lightweight Nature

Aluminum is inherently lightweight compared to other metals like steel. This property allows for easier handling and installation of components in automated systems, leading to reduced energy consumption and improved overall efficiency.

3. Cost-Effectiveness

While the initial setup costs for aluminum extrusion can be high due to die creation, the long-term savings are substantial. Mass production of extruded components reduces the cost per unit significantly, making it an economically viable option for manufacturers.

4. Enhanced Durability

Aluminum's natural resistance to corrosion ensures that extruded components have a longer lifespan with minimal maintenance required. This durability is essential in automation systems that operate continuously under varying environmental conditions.

5. Reduced Labor Costs

Automated systems utilizing aluminum extrusions can minimize manual handling, reducing labor costs and potential human errors during assembly or production processes.

Applications of Aluminum Extrusion in Automation

Aluminum extrusion finds applications in various automated systems across multiple industries:

- Assembly Line Construction: Aluminum extrusions are used to build modular assembly lines that can be easily reconfigured as production needs change.

- Robotic Systems: The lightweight nature of aluminum makes it ideal for constructing robotic arms and frameworks that require precision and strength without added weight.

- Material Handling Equipment: Extruded aluminum is commonly used in conveyor systems, storage racks, and other material handling solutions due to its strength and adaptability.

- Safety Enclosures: Aluminum profiles are utilized to create safety barriers and enclosures around machinery, ensuring operator safety while maintaining visibility.

- Control Systems: The versatility of aluminum allows for the creation of housings and supports for control panels and sensors within automated environments.

How Automation Enhances Aluminum Extrusion Processes

The integration of automation technologies in aluminum extrusion processes further improves efficiency:

- Automated Material Handling Systems (AMHS): These systems streamline the movement of materials throughout the production process, reducing wait times and increasing throughput.

- AI-Powered Quality Control: Automated inspection systems utilize AI to monitor product quality in real-time, ensuring that defects are caught early in the production cycle.

- Robotic Assembly Lines: Robots can assemble extruded components with precision, reducing assembly time and improving product consistency.

Advantages of Automated Material Handling

Automated material handling systems play a critical role in enhancing the efficiency of aluminum extrusion operations:

- Speeding Up Processes: Automated systems can move materials quickly between different stages of production without delays caused by manual handling.

- Reducing Labor Costs: By minimizing manual labor requirements, companies can lower operational costs while reallocating human resources to more complex tasks that require decision-making skills.

- Improving Safety: Reducing human intervention in potentially hazardous environments decreases the likelihood of workplace injuries associated with heavy lifting or equipment operation.

- Ensuring Quality Control: Automated material handling helps maintain consistent quality by reducing human error during transportation and assembly processes[1].

Visualizing the Process

To better understand how aluminum extrusion enhances automation efficiency, consider the following visual representations:

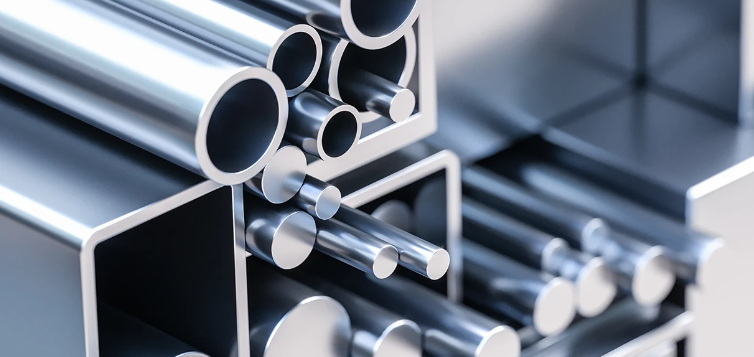

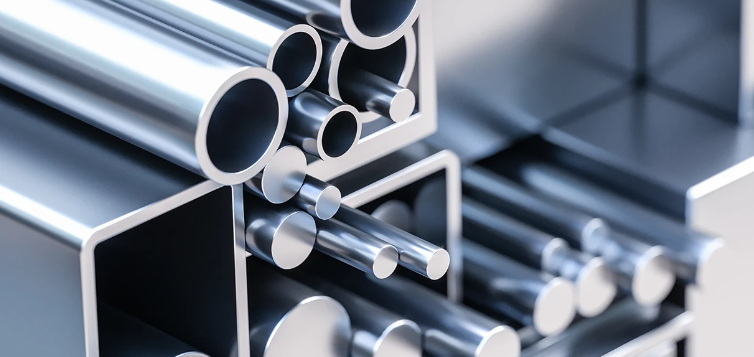

Aluminum Extrusion Process

*Figure 1: Overview of the Aluminum Extrusion Process*

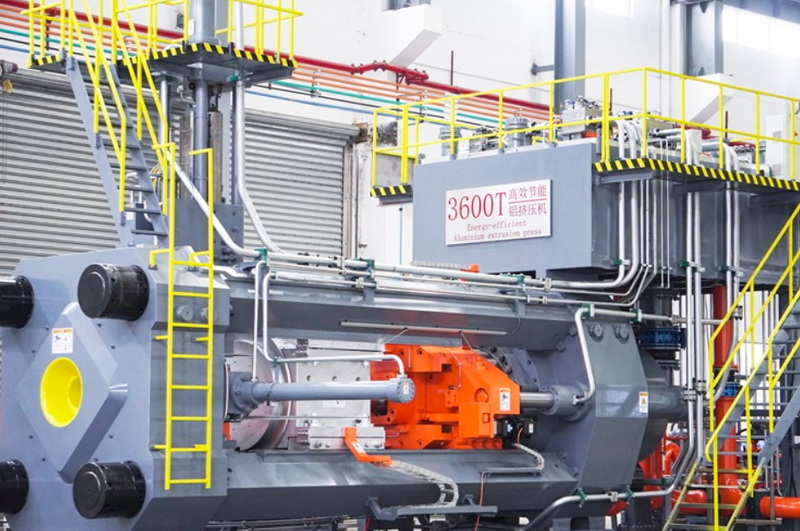

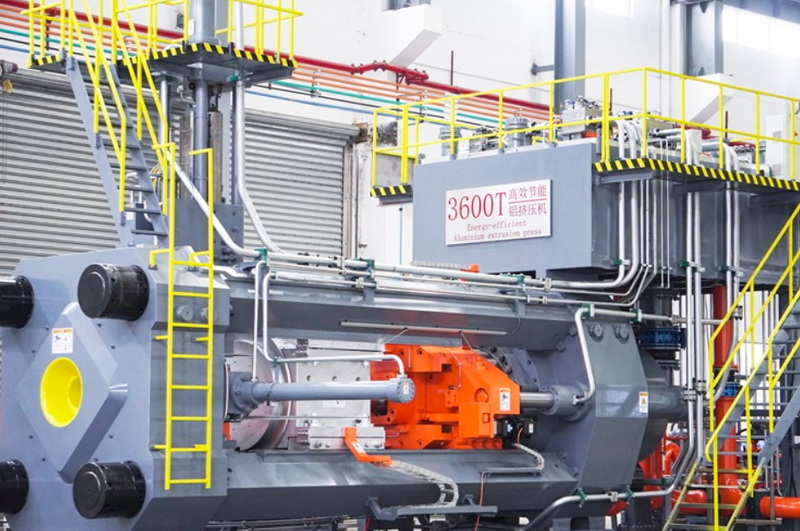

Automated Assembly Line

*Figure 2: Example of an Automated Assembly Line Using Aluminum Extrusions*

Case Studies

Several companies have successfully implemented aluminum extrusion in their automated processes:

- Company A: By integrating aluminum extrusions into their robotic assembly line, Company A reduced assembly time by 30% while improving product accuracy.

- Company B: Utilizing automated material handling with extruded components allowed Company B to increase their production capacity by 50%, significantly lowering operational costs[2].

Expanding Applications of Aluminum Extrusions

The versatility of aluminum extrusion extends beyond traditional applications:

- Industrial Ladders: Used extensively in factories, these ladders benefit from the lightweight yet sturdy nature of aluminum extrusions, making them easy to transport and maneuver while ensuring safety during use[5].

- Workstations: Customizable workstations made from aluminum extrusions are prevalent across various industries. They offer flexibility for different tasks while maintaining structural integrity[4].

- Machine Guarding Systems: These systems enhance workplace safety by using aluminum profiles to create barriers around machinery[2].

- Clean Rooms: In industries requiring sterile environments, anodized aluminum extrusions are used to construct cleanroom walls and structures that resist dust accumulation[5].

Future Trends in Aluminum Extrusion Automation

As technology advances, several trends are shaping the future of aluminum extrusion within automated environments:

1. Increased Use of Robotics

The integration of robotics into manufacturing processes will continue to grow. Robots equipped with vision systems can perform intricate tasks such as welding or painting on extruded components with high precision[3].

2. Smart Manufacturing

The adoption of IoT devices will enable real-time monitoring and data collection throughout the extrusion process. This information will facilitate predictive maintenance strategies, reducing downtime and enhancing productivity[6].

3. Sustainable Practices

With growing environmental concerns, manufacturers are focusing on sustainability initiatives such as recycling scrap aluminum from production processes and utilizing renewable energy sources[6].

4. Advanced Alloys

Research into new alloys will lead to improved performance characteristics such as enhanced strength-to-weight ratios or better corrosion resistance—key factors for applications in demanding environments like aerospace or automotive industries[7].

Conclusion

The integration of aluminum extrusion into automated systems offers numerous benefits that enhance overall efficiency. From design flexibility and cost-effectiveness to durability and reduced labor costs, aluminum extrusions are pivotal in modern manufacturing environments. As industries continue to evolve towards greater automation, the role of aluminum extrusion will become increasingly vital in meeting production demands while maintaining high standards of quality and sustainability.

FAQ

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy by forcing it through a die under high pressure to create specific profiles or shapes.

2. How does aluminum extrusion improve automation efficiency?

Aluminum extrusion enhances automation efficiency by providing lightweight, durable components that offer design flexibility, reduce labor costs, and improve overall production speed.

3. What industries benefit from aluminum extrusion?

Industries such as automotive, aerospace, construction, and electronics benefit significantly from aluminum extrusion due to its versatile applications and properties.

4. Can aluminum extrusions be customized?

Yes, aluminum extrusions can be customized in terms of shape, size, and finish to meet specific requirements for various applications.

5. What are some common applications of aluminum extrusions in automation?

Common applications include assembly line construction, robotic systems, material handling equipment, safety enclosures, and control system supports.

Citations:

[1] https://www.odmetals.com/blog/how-is-automated-material-handling-helping-aluminum-extrusion-suppliers

[2] https://www.linkedin.com/pulse/7-common-applications-industrial-aluminum

[3] https://elkamehr.com/en/automation-and-robotics-in-aluminum-manufacturing-enhancing-efficiency/

[4] https://info.izumiinternational.com/3-advantages-of-aluminium-extrusion-frames-over-welded-steel

[5] https://proax.ca/en/blog/post/aluminum-extrusion-manufacturing-applications

[6] https://www.atieuno.com/2023/10/09/aluminium-extrusion-manufacturers/

[7] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[8] https://www.unisontek.com.tw

[9] https://conceptsystemsinc.com/case-studies/

[10] https://kimsen.vn/an-introduction-to-aluminum-extrusion-and-profiles-ne46.html