Content Menu

● Overview of Aluminum Extrusion 6063

● Aluminum Extrusion Process

● Comparison with Other Aluminum Alloys

● Mechanical Properties

>> Aluminum Extrusion 6063

>> Aluminum Extrusion 6061

>> Aluminum Extrusion 6082

● Applications of Aluminum Extrusion 6063

● Advantages of Using Aluminum Extrusion 6063

● Environmental Considerations

● Surface Treatments

>> Anodizing

>> Powder Coating

>> Painting

● Challenges with Aluminum Extrusion 6063

● Future Trends in Aluminum Extrusion

● Conclusion

● FAQ

>> 1.What is the primary use of aluminum extrusion 6063?

>> 2.How does aluminum extrusion 6063 compare to aluminum extrusion 6061?

>> 3.Can aluminum extrusion 6063 be anodized?

>> 4.What are the mechanical properties of aluminum extrusion 6063?

>> 5.Is aluminum extrusion 6063 suitable for outdoor use?

Aluminum extrusion is a process that shapes aluminum alloy into desired profiles by forcing it through a die. Among the various aluminum alloys available, 6063 aluminum stands out due to its unique properties and versatility. This article will explore how aluminum extrusion 6063 compares to other popular alloys, particularly 6061 and 6082, focusing on their mechanical properties, applications, and advantages.

Overview of Aluminum Extrusion 6063

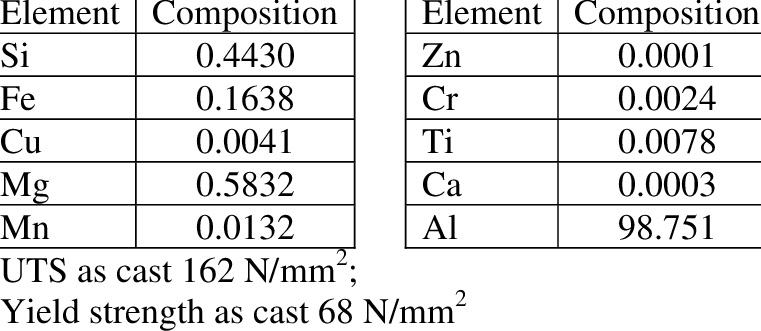

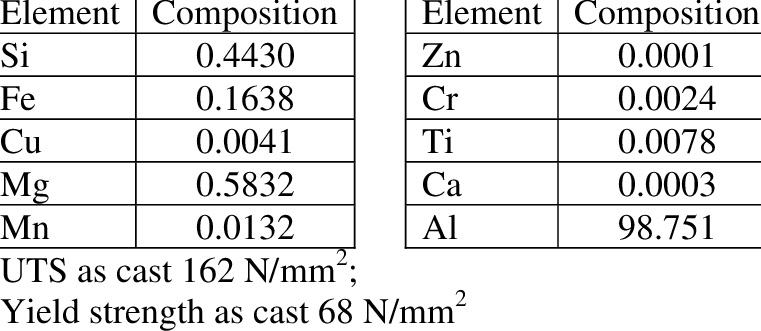

Aluminum alloy 6063 is often referred to as an architectural alloy due to its excellent extrudability and aesthetic finish. It primarily consists of magnesium and silicon, which contribute to its desirable characteristics. Here are some key properties of 6063 aluminum:

- Density: 2.69 g/cm³

- Tensile Strength: Ranges from 145 to 186 MPa (21.0–27.0 ksi)

- Elongation at Break: 18–33%

- Thermal Conductivity: 201–218 W/(m·K)

- Corrosion Resistance: Excellent

These properties make 6063 aluminum ideal for applications that require intricate shapes and high-quality surface finishes, such as window frames, door frames, and architectural components.

Aluminum Extrusion Process

The aluminum extrusion process involves several steps:

1. Billet Preparation: The aluminum alloy is heated to a specific temperature to soften it for easier shaping.

2. Extrusion: The softened billet is placed in a press, where it is forced through a die to create the desired profile.

3. Cooling: The extruded profile is cooled, typically using air or water, to solidify the shape.

4. Stretching: The profile is stretched to eliminate any internal stresses and ensure dimensional accuracy.

5. Cutting: Finally, the extruded lengths are cut to the required sizes for various applications.

Comparison with Other Aluminum Alloys

To understand the advantages of 6063 aluminum, it is essential to compare it with other commonly used alloys like 6061 and 6082.

| Property | Aluminum 6063 | Aluminum 6061 | Aluminum 6082 |

| Density | 2.69 g/cm³ | 2.70 g/cm³ | 2.70 g/cm³ |

| Tensile Strength | 145–186 MPa | 260–310 MPa | 260–310 MPa |

| Yield Strength | 90 MPa | 240 MPa | 240 MPa |

| Elongation at Break | 18–33% | 12–17% | 12–16% |

| Corrosion Resistance | Excellent | Good | Good |

| Workability | Excellent | Good | Good |

| Anodizing Quality | Excellent | Good | Moderate |

Mechanical Properties

The mechanical properties of aluminum alloys play a crucial role in determining their suitability for various applications.

Aluminum Extrusion 6063

- Strength: While not the strongest alloy, its tensile strength is adequate for many architectural applications.

- Workability: The alloy is highly workable, allowing for complex shapes and designs.

- Corrosion Resistance: Offers excellent resistance to corrosion, making it suitable for outdoor applications.

Aluminum Extrusion 6061

- Strength: Known for its high strength, making it ideal for structural applications.

- Workability: While still workable, it is less so than 6063, especially in intricate designs.

- Corrosion Resistance: Good but not as high as that of 6063.

Aluminum Extrusion 6082

- Strength: Similar to 6061, but with slightly better corrosion resistance.

- Workability: Good but not as easy to extrude as 6063.

- Corrosion Resistance: Comparable to that of 6061.

Applications of Aluminum Extrusion 6063

The versatility of aluminum extrusion 6063 makes it suitable for a wide range of applications:

- Architectural Applications: Used extensively in window frames, door frames, curtain walls, and structural tubing due to its aesthetic appeal and excellent surface finish.

- Automotive Industry: Commonly used in interior trim and structural components where weight reduction is critical without compromising strength.

- Electronics: Utilized in heat sinks and enclosures due to its thermal conductivity.

- Recreational Equipment: Found in bicycle frames and camping gear due to its lightweight nature.

Advantages of Using Aluminum Extrusion 6063

Choosing aluminum extrusion 6063 offers several benefits:

- Aesthetic Quality: Produces smooth surfaces that can be anodized or painted for enhanced visual appeal.

- Ease of Fabrication: Its excellent workability allows for intricate designs that are challenging with other alloys.

- Cost-Effectiveness: Generally less expensive than higher-strength alloys like 6061, making it a preferred choice for budget-sensitive projects.

Environmental Considerations

Aluminum extrusion also has significant environmental benefits:

- Recyclability: Aluminum can be recycled repeatedly without losing its properties. This makes it an environmentally friendly choice compared to other materials like steel or plastic.

- Lightweight Nature: The lightweight nature of aluminum reduces transportation costs and energy consumption during manufacturing processes.

Surface Treatments

One of the significant advantages of using aluminum extrusion 6063 is its compatibility with various surface treatments:

Anodizing

Anodizing enhances corrosion resistance and provides a durable finish that can be dyed in various colors. This treatment is particularly beneficial for architectural applications where aesthetics are crucial.

Powder Coating

Powder coating provides a thicker finish than traditional paint, offering better protection against scratches and wear while allowing for a wide range of color options.

Painting

Painting can also be used on aluminum extrusion profiles, providing additional protection against environmental factors while enhancing visual appeal.

Challenges with Aluminum Extrusion 6063

While there are many advantages to using aluminum extrusion 6063, there are also challenges associated with its use:

- Lower Strength Compared to Other Alloys: For applications requiring high strength-to-weight ratios, other alloys like 6061 may be more appropriate.

- Cost Variability: Although generally cost-effective, fluctuations in raw material prices can affect the overall cost-effectiveness of projects utilizing this alloy.

Future Trends in Aluminum Extrusion

As industries evolve, so do the technologies associated with aluminum extrusion. Some future trends include:

- Advanced Alloys Development: Research into new aluminum alloys that enhance strength while maintaining workability will continue.

- Sustainability Practices: Increased focus on sustainable practices within manufacturing processes will drive innovations in recycling and energy efficiency in extrusion operations.

Conclusion

In conclusion, while aluminum extrusion alloys like 6061 and 6082 offer higher strength, the unique properties of aluminum extrusion 6063 make it an exceptional choice for a variety of applications, particularly in architecture and design. Its combination of good mechanical properties, excellent corrosion resistance, and superior extrudability makes it a go-to material for many industries. As we move toward more sustainable practices and advanced technologies in manufacturing, the relevance of aluminum extrusion—especially the versatile alloy 6063—will undoubtedly continue to grow.

FAQ

1.What is the primary use of aluminum extrusion 6063?

Aluminum extrusion 6063 is primarily used in architectural applications such as window frames, door frames, and curtain walls due to its excellent surface finish and workability.

2.How does aluminum extrusion 6063 compare to aluminum extrusion 6061?

While both are used in similar applications, aluminum extrusion 6061 offers higher strength compared to aluminum extrusion 6063, making it more suitable for structural uses.

3.Can aluminum extrusion 6063 be anodized?

Yes, aluminum extrusion 6063 can be easily anodized, enhancing its corrosion resistance and aesthetic appeal.

4.What are the mechanical properties of aluminum extrusion 6063?

Aluminum extrusion 6063 has a tensile strength ranging from 145 to 186 MPa and an elongation at break between 18% and 33%.

5.Is aluminum extrusion 6063 suitable for outdoor use?

Yes, due to its excellent corrosion resistance, aluminum extrusion 6063 is well-suited for outdoor applications where exposure to the elements is a concern.