Content Menu

● Introduction to Aluminum Extrusion

>> Working Principle of Aluminum Extrusion Machines

>> Steps in the Extrusion Process

● Solar Aluminum Bearing Extruder

>> Applications in Solar Industry

>> Manufacturing Process for Solar Aluminum Frames

● Building a Solar Panel Rack with Aluminum Extrusions

● Slide Bearing Assembly for Aluminum Profiles

● Advantages of Solar Aluminum Bearing Extruders

● Challenges and Future Developments

● Conclusion

● FAQs

>> 1. What is the primary function of a solar aluminum bearing extruder?

>> 2. How does the extrusion process work?

>> 3. What are the advantages of using aluminum extrusions in solar applications?

>> 4. How are solar aluminum frames manufactured?

>> 5. What role do slide bearing assemblies play in solar panel systems?

The solar aluminum bearing extruder is a crucial component in the production of solar panel frames and other solar-related structures. It utilizes aluminum extrusion technology to create profiles that are essential for supporting solar panels. In this article, we will delve into the working principle of a solar aluminum bearing extruder, its applications, and the manufacturing process involved.

Introduction to Aluminum Extrusion

Aluminum extrusion is a process used to create aluminum profiles by forcing heated aluminum through a die. This process is widely used in various industries, including construction, automotive, and solar energy. The versatility of aluminum extrusion lies in its ability to produce complex shapes with precise dimensions, making it ideal for applications where customization is key.

Working Principle of Aluminum Extrusion Machines

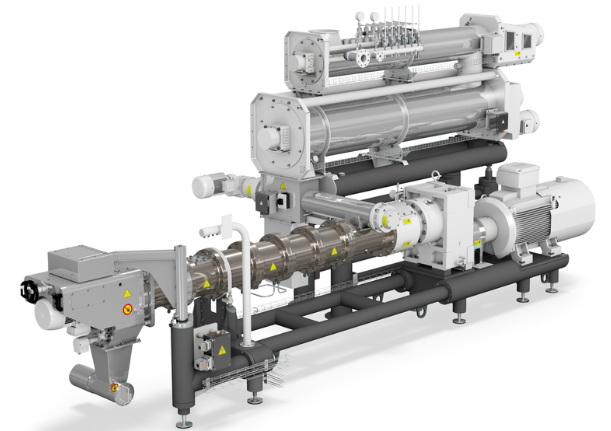

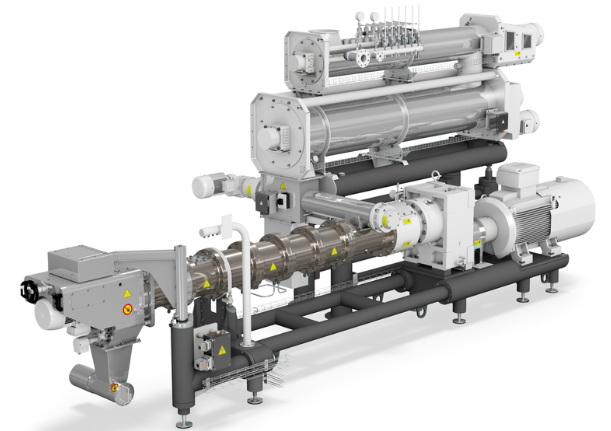

An aluminum extrusion machine consists of three main parts: the extrusion head, hydraulic system, and control system.

1. Extrusion Head: This includes a mold, heater, pretreatment device, and extrusion cavity. The mold shapes the aluminum into the desired profile, while the heater softens the aluminum to make it pliable. The pretreatment device removes oxide scales and applies lubricants to facilitate smooth extrusion.

2. Hydraulic System: This system generates the high pressure needed to push the aluminum through the mold. It consists of a fuel tank, oil pump, high-pressure cylinder, low-pressure cylinder, valves, and pipelines. The hydraulic system is critical for maintaining consistent pressure during the extrusion process.

3. Control System: This system controls the operation of the machine using a PLC controller, human-machine interface, and electrical components like sensors and relays. The control system ensures that the extrusion process is automated and efficient, allowing for precise control over temperature, pressure, and speed.

Steps in the Extrusion Process

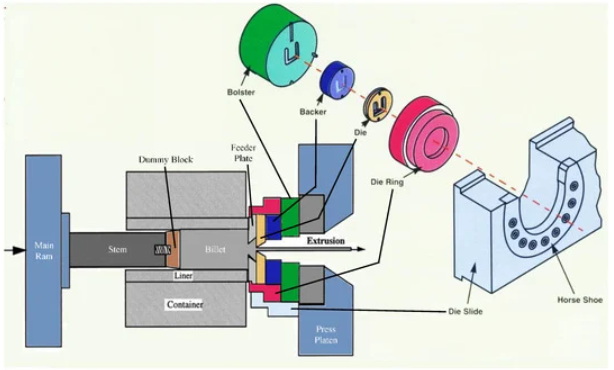

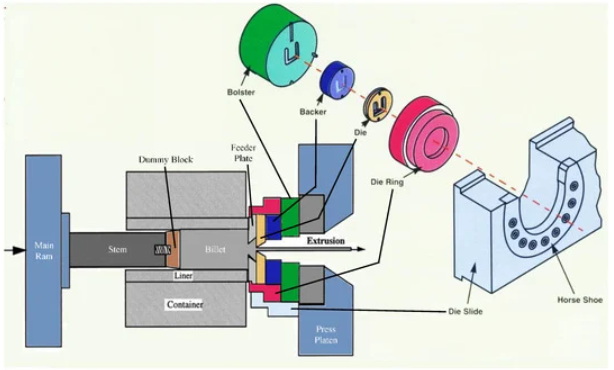

- Heating: Aluminum rods or plates are heated to a temperature between 300°C and 500°C. This heating process is crucial for reducing the aluminum's viscosity and making it easier to shape.

- Feeding: The heated aluminum is fed into the extrusion cavity. Proper alignment is essential to ensure that the aluminum flows smoothly through the mold.

- Pretreatment: The aluminum is pre-extruded to fit the mold closely. This step helps in removing any impurities and ensures that the aluminum adheres well to the mold.

- Extrusion: High pressure is applied to push the aluminum through the mold. The pressure must be carefully controlled to achieve the desired profile without causing defects.

- Cutting: The extruded profile is cut to the desired length. This can be done using a variety of cutting tools, depending on the precision required.

Solar Aluminum Bearing Extruder

A solar aluminum bearing extruder specifically produces profiles used in solar panel frames and other solar applications. These profiles are designed to support solar panels securely and efficiently, ensuring that they can withstand environmental conditions such as wind and rain.

Applications in Solar Industry

Aluminum extrusion profiles are widely used in the solar industry for several reasons:

- Durability: Aluminum is resistant to corrosion, making it ideal for outdoor applications where exposure to moisture is common.

- Lightweight: Aluminum profiles are lightweight, reducing the overall weight of solar panel systems. This makes them easier to transport and install.

- Customization: Profiles can be customized to fit various solar panel sizes and shapes. This flexibility allows manufacturers to design systems that are tailored to specific solar panel configurations.

Manufacturing Process for Solar Aluminum Frames

The manufacturing process for solar aluminum frames involves several steps:

1. Extrusion: Aluminum profiles are extruded using a solar aluminum bearing extruder. The extrusion process is critical for creating profiles with precise dimensions.

2. Straightening: Newly extruded profiles are straightened to prevent bending. Straightening ensures that the profiles are perfectly aligned, which is essential for structural integrity.

3. Aging: Profiles are heated to increase strength. This process, known as aging, enhances the mechanical properties of the aluminum, making it more durable.

4. Sandblasting: Profiles are sandblasted for a matte finish. Sandblasting helps in creating a surface that is suitable for further treatments like anodizing.

5. Anodizing: Profiles are anodized for corrosion resistance. Anodizing creates a protective layer on the aluminum surface, which protects it from environmental degradation.

6. Sawing: Profiles are cut to size. Precision cutting is crucial to ensure that the profiles fit perfectly into the solar panel frame.

7. Assembly: Frames are assembled with corners and rivets. The assembly process involves carefully fitting the profiles together to form a sturdy frame that can support solar panels securely.

Building a Solar Panel Rack with Aluminum Extrusions

Watching videos on how to build solar panel racks using aluminum extrusions can provide valuable insights into the practical applications of these profiles. Such videos often demonstrate how to design and assemble a rack that is both durable and efficient.

Slide Bearing Assembly for Aluminum Profiles

Slide bearing assemblies are used to create moving parts on aluminum profiles, which can be useful in solar panel tracking systems. These assemblies consist of bearings mounted on eccentric nuts, allowing for smooth movement along the profile. This feature is particularly beneficial in solar tracking systems, where panels need to adjust their angle to maximize sun exposure throughout the day.

Advantages of Solar Aluminum Bearing Extruders

Solar aluminum bearing extruders offer several advantages in the production of solar panel frames:

- Efficiency: These extruders can produce profiles at high speeds, making them efficient for large-scale production.

- Customization: They allow for the creation of customized profiles that fit specific solar panel designs.

- Durability: The profiles produced are durable and resistant to corrosion, ensuring long-lasting performance.

Challenges and Future Developments

Despite the advantages of solar aluminum bearing extruders, there are challenges that need to be addressed. One of the main challenges is the energy consumption of the extrusion process. Future developments may focus on integrating renewable energy sources into the manufacturing process to reduce carbon footprint.

Additionally, advancements in material science could lead to the development of new aluminum alloys that are even more durable and lightweight. Such innovations would further enhance the efficiency and sustainability of solar panel systems.

Conclusion

In conclusion, a solar aluminum bearing extruder plays a vital role in producing profiles for solar panel frames and other solar applications. Its ability to create customized, durable, and lightweight profiles makes it an essential tool in the solar industry. Understanding how these extruders work and their applications can help in optimizing solar panel systems for better efficiency and sustainability.

FAQs

1. What is the primary function of a solar aluminum bearing extruder?

A solar aluminum bearing extruder is primarily used to produce aluminum profiles that are customized for supporting solar panels and other solar-related structures. These profiles are designed to be durable, lightweight, and corrosion-resistant.

2. How does the extrusion process work?

The extrusion process involves heating aluminum rods or plates to make them pliable, then forcing them through a die using high pressure generated by a hydraulic system. This process shapes the aluminum into the desired profile.

3. What are the advantages of using aluminum extrusions in solar applications?

Aluminum extrusions offer several advantages in solar applications, including durability, lightweight construction, and customization options. They are also resistant to corrosion, making them suitable for outdoor use.

4. How are solar aluminum frames manufactured?

The manufacturing process for solar aluminum frames includes extrusion, straightening, aging, sandblasting, anodizing, sawing, and assembly. Each step ensures that the frames are strong, durable, and aesthetically pleasing.

5. What role do slide bearing assemblies play in solar panel systems?

Slide bearing assemblies are used to create moving parts on aluminum profiles, which can be useful in solar panel tracking systems. They allow for smooth movement and can enhance the efficiency of solar panel systems by optimizing sun exposure.