Content Menu

● Understanding Aluminum Extrusion

>> The Basics of Aluminum Alloys

● What is 80/40 Aluminum Extrusion?

>> Characteristics of 80/40 Aluminum Extrusion

● Comparing 80/40 Aluminum Extrusion to Other Sizes

>> 1. 30/30 Aluminum Extrusion

>> 2. 40/40 Aluminum Extrusion

>> 3. 80/80 Aluminum Extrusion

● Applications of 80/40 Aluminum Extrusion

● Advantages of Using 80/40 Aluminum Extrusion

● Factors to Consider When Choosing Aluminum Extrusion Sizes

● Conclusion

● Frequently Asked Questions

>> 1. What is the difference between 80/40 and 40/40 aluminum extrusions?

>> 2. Can I use 80/40 aluminum extrusion for outdoor applications?

>> 3. How do I cut 80/40 aluminum extrusion?

>> 4. Is it easy to modify structures made from 80/40 aluminum extrusion?

>> 5. What tools do I need to assemble 80/40 aluminum extrusion?

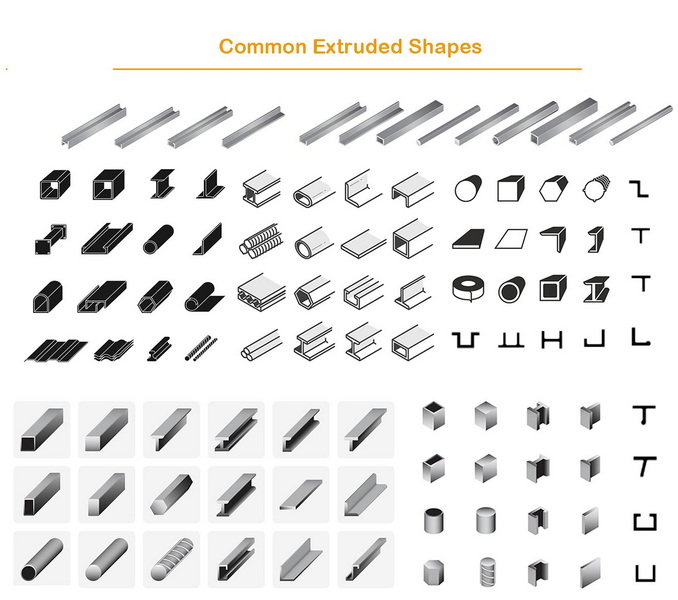

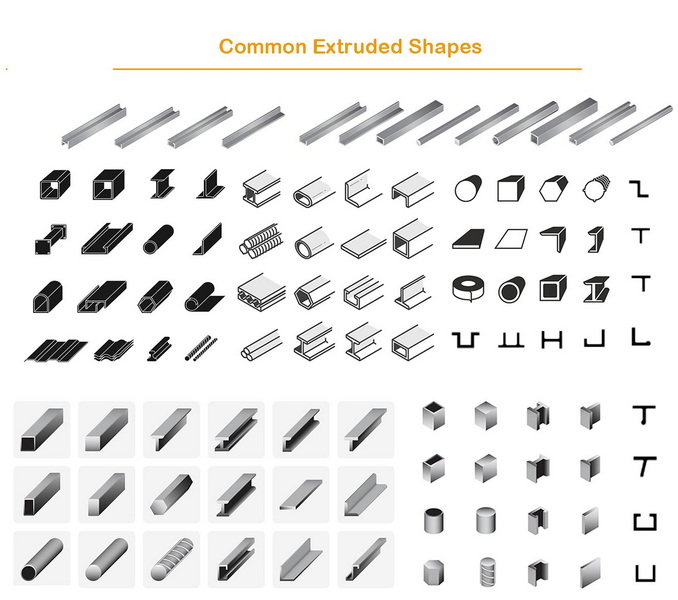

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This process is widely used in various industries due to the material's lightweight, strength, and versatility. Among the many sizes available, the 80/40 aluminum extrusion is particularly popular. In this article, we will explore how the 80/40 aluminum extrusion compares to other extrusion sizes, discussing its applications, advantages, and the factors that influence its selection.

Understanding Aluminum Extrusion

Before diving into the specifics of the 80/40 aluminum extrusion, it is essential to understand what aluminum extrusion is and how it works. The extrusion process involves forcing aluminum alloy through a die, which shapes it into a continuous profile. This method allows for the creation of complex shapes that can be used in various applications, from structural components to decorative elements.

The Basics of Aluminum Alloys

Aluminum alloys are categorized into two main types: wrought and cast. Wrought alloys are those that are mechanically worked into shape, while cast alloys are poured into molds. The most common alloys used in extrusion are 6061 and 6063, known for their excellent mechanical properties and corrosion resistance. The choice of alloy can significantly affect the performance of the final product.

What is 80/40 Aluminum Extrusion?

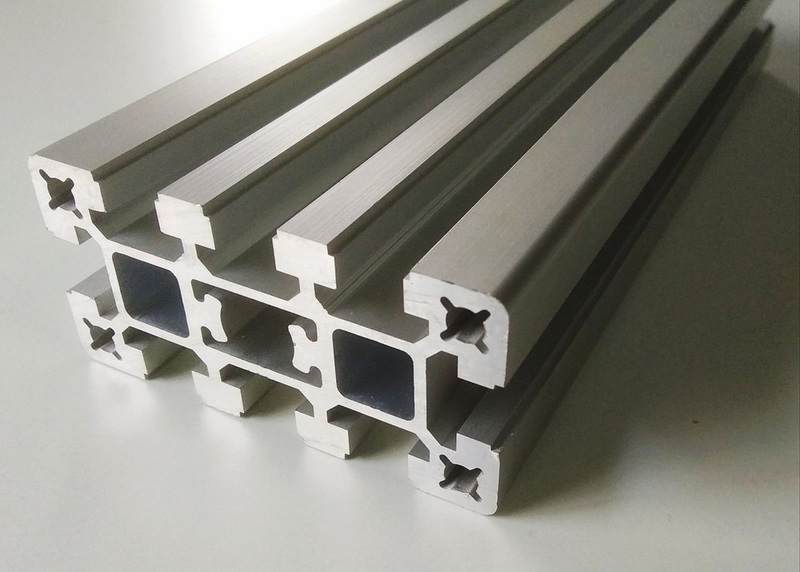

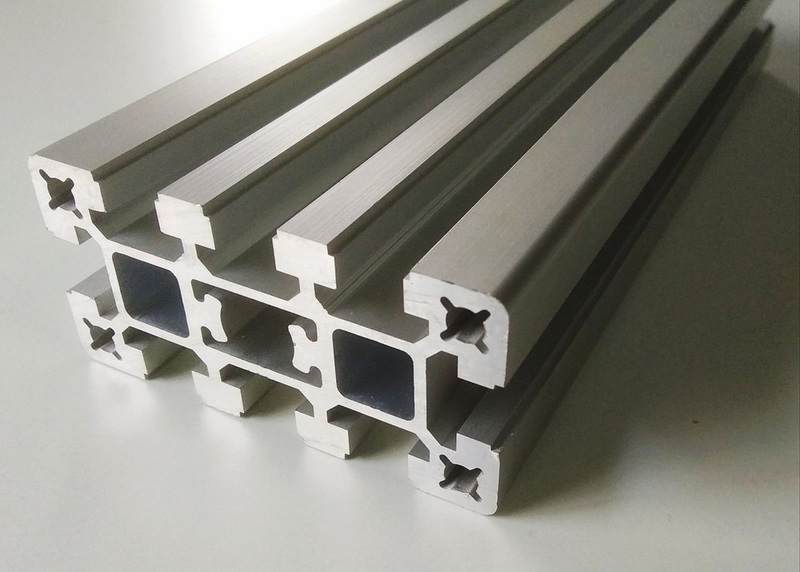

The designation "80/40" refers to the dimensions of the aluminum extrusion profile. Specifically, it indicates that the profile is 80 mm wide and 40 mm high. This size is part of the metric series of aluminum extrusions, which are commonly used in Europe and other regions that utilize the metric system.

Characteristics of 80/40 Aluminum Extrusion

1. Versatility: The 80/40 profile is versatile and can be used in various applications, including machine frames, workstations, and enclosures.

2. Strength: With its robust design, the 80/40 extrusion can support significant loads, making it suitable for structural applications.

3. T-Slot Design: The T-slot design allows for easy assembly and disassembly, enabling users to create custom structures without the need for specialized tools.

4. Compatibility: The 80/40 extrusion is compatible with other sizes in the metric series, allowing for flexibility in design and construction.

Comparing 80/40 Aluminum Extrusion to Other Sizes

When comparing the 80/40 aluminum extrusion to other sizes, several factors come into play, including dimensions, load capacity, and application suitability. Here, we will compare the 80/40 extrusion to some common alternatives, such as 30/30, 40/40, and 80/80 profiles.

1. 30/30 Aluminum Extrusion

The 30/30 aluminum extrusion is smaller, measuring 30 mm by 30 mm. This size is ideal for lightweight applications, such as small frames and enclosures. While it is easier to handle and assemble due to its smaller size, it cannot support the same load as the 80/40 extrusion. Therefore, the 30/30 profile is best suited for applications where weight is a concern, and structural integrity is less critical.

2. 40/40 Aluminum Extrusion

The 40/40 aluminum extrusion measures 40 mm by 40 mm and offers a balance between size and strength. It is commonly used in applications that require moderate load-bearing capabilities, such as workstations and light machinery. While the 40/40 profile is stronger than the 30/30, it still falls short of the load capacity provided by the 80/40 extrusion. Users looking for a robust solution for heavier applications will find the 80/40 extrusion more suitable.

3. 80/80 Aluminum Extrusion

On the other end of the spectrum, the 80/80 aluminum extrusion measures 80 mm by 80 mm. This profile is designed for heavy-duty applications, providing maximum strength and stability. While it offers superior load-bearing capabilities compared to the 80/40 extrusion, it is also heavier and more expensive. The choice between the 80/40 and 80/80 profiles will depend on the specific requirements of the project, including weight constraints and budget considerations.

Applications of 80/40 Aluminum Extrusion

The 80/40 aluminum extrusion is used in a wide range of applications across various industries. Some common uses include:

- Machine Frames: The strength and stability of the 80/40 profile make it an excellent choice for constructing machine frames that require durability and precision.

- Workstations: Many manufacturing and assembly operations utilize 80/40 extrusions to create customizable workstations that can be easily reconfigured as needed.

- Enclosures: The T-slot design allows for the easy assembly of enclosures for machinery and equipment, providing protection while maintaining accessibility.

- Robotics: The lightweight yet strong nature of the 80/40 extrusion makes it ideal for building robotic structures and supports.

Advantages of Using 80/40 Aluminum Extrusion

1. Ease of Assembly: The T-slot design allows for quick and easy assembly without the need for specialized tools, making it accessible for users of all skill levels.

2. Customization: The ability to easily modify and adapt structures using 80/40 extrusions allows for greater flexibility in design.

3. Cost-Effectiveness: While the initial investment may be higher than other materials, the long-term durability and low maintenance costs of aluminum make it a cost-effective choice.

4. Corrosion Resistance: Aluminum naturally resists corrosion, making it suitable for use in various environments, including those with high humidity or exposure to chemicals.

Factors to Consider When Choosing Aluminum Extrusion Sizes

When selecting the appropriate aluminum extrusion size for a project, several factors should be considered:

1. Load Requirements: Assess the weight and load that the structure will need to support. This will help determine whether the 80/40 extrusion or another size is more appropriate.

2. Space Constraints: Consider the available space for the structure. In tight spaces, smaller profiles like the 30/30 may be more suitable.

3. Assembly Complexity: Evaluate how complex the assembly process will be. T-slot designs simplify assembly, but larger profiles may require more planning.

4. Budget: Determine the budget for the project. While larger profiles may offer more strength, they can also be more expensive.

Conclusion

In conclusion, the 80/40 aluminum extrusion is a versatile and robust option for various applications. Its unique characteristics, such as the T-slot design and compatibility with other sizes, make it an excellent choice for those seeking a balance between strength and ease of use. When comparing it to other extrusion sizes, it is essential to consider the specific requirements of the project, including load capacity, space constraints, and budget. By understanding these factors, users can make informed decisions that lead to successful outcomes in their projects.

Frequently Asked Questions

1. What is the difference between 80/40 and 40/40 aluminum extrusions?

The 80/40 aluminum extrusion is larger and can support heavier loads compared to the 40/40 extrusion, which is more suitable for lighter applications.

2. Can I use 80/40 aluminum extrusion for outdoor applications?

Yes, aluminum is naturally resistant to corrosion, making it suitable for outdoor use. However, consider the environmental conditions and potential exposure to harsh elements.

3. How do I cut 80/40 aluminum extrusion?

You can cut aluminum extrusion using a miter saw with a fine-toothed blade or a band saw. Ensure to measure accurately and secure the profile during cutting.

4. Is it easy to modify structures made from 80/40 aluminum extrusion?

Yes, the T-slot design allows for easy modifications and reconfigurations, making it simple to adapt structures as needed.

5. What tools do I need to assemble 80/40 aluminum extrusion?

Basic tools such as an Allen wrench, a screwdriver, and a saw for cutting are typically sufficient for assembling structures using 80/40 aluminum extrusion.