Content Menu

● Understanding Aluminum Extrusion

>> What is 6040 Aluminum Extrusion?

● Comparison with Other Aluminum Profiles

>> Dimensions and Versatility

>> Strength and Load-Bearing Capacity

>> Machinability and Fabrication

>> Cost Considerations

>> Applications of 6040 Aluminum Extrusion

● Advantages of 6040 Aluminum Extrusion

● Limitations of 6040 Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What are the main uses of 6040 aluminum extrusion?

>> 2. How does the strength of 6040 aluminum extrusion compare to smaller profiles?

>> 3. Is 6040 aluminum extrusion easy to machine?

>> 4. What are the environmental benefits of using aluminum extrusion?

>> 5. Can 6040 aluminum extrusion be customized?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. Among the various profiles available, the 6040 aluminum extrusion stands out due to its unique dimensions and versatility. This article will explore how the 6040 aluminum extrusion compares to other aluminum profiles, focusing on its applications, advantages, and limitations.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing aluminum alloy through a die to create a specific shape. This process allows for the production of complex cross-sectional shapes that can be used in a variety of applications, from construction to automotive parts. The most common aluminum alloys used in extrusion include 6061, 6063, and 6082, each offering different properties suited for specific applications.

What is 6040 Aluminum Extrusion?

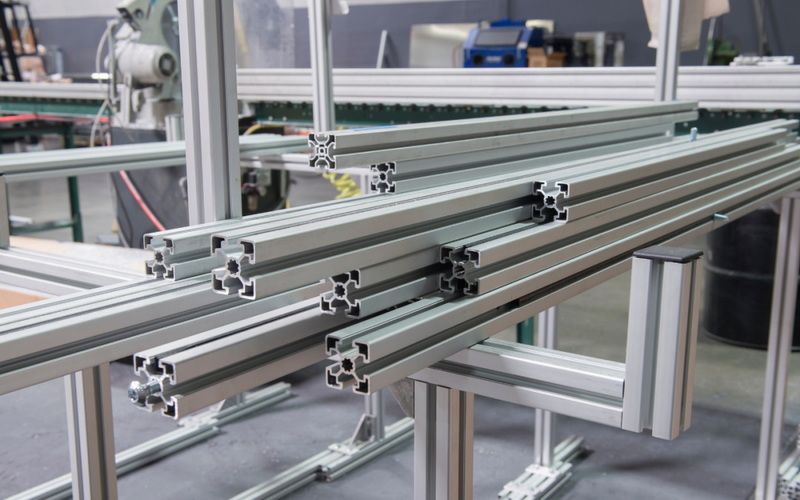

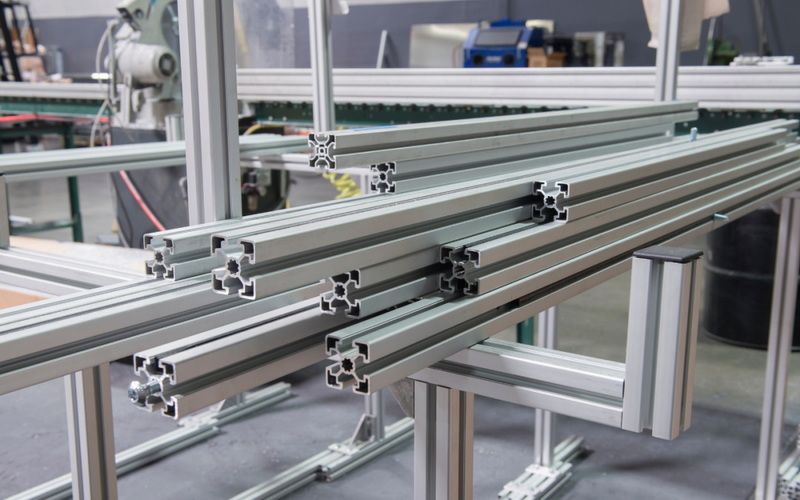

The term "6040" refers to the dimensions of the aluminum profile, specifically 60mm by 40mm. This profile is part of the T-slot aluminum extrusion family, which features grooves along its length, allowing for easy assembly and integration with other components. The 6040 profile is particularly popular in modular construction, robotics, and automation systems due to its strength and adaptability.

Comparison with Other Aluminum Profiles

Dimensions and Versatility

When comparing the 6040 aluminum extrusion to other profiles, one of the most significant factors is its dimensions. The 6040 profile is larger than smaller profiles like the 2020 (20mm x 20mm) and 3030 (30mm x 30mm) extrusions, making it suitable for applications that require greater structural integrity.

The versatility of the 6040 profile allows it to be used in various configurations, including frames, supports, and enclosures. Its T-slot design enables users to easily connect multiple profiles, creating custom structures without the need for complex machining. This adaptability is particularly beneficial in environments where designs need to be modified or expanded over time.

Strength and Load-Bearing Capacity

The strength of an aluminum profile is crucial in determining its suitability for specific applications. The 6040 aluminum extrusion, typically made from 6063 or 6061 alloys, offers excellent strength-to-weight ratios.

- 6063 Aluminum Alloy: Known for its good corrosion resistance and surface finish, 6063 is often used in architectural applications. It provides adequate strength for most structural applications while allowing for intricate designs.

- 6061 Aluminum Alloy: This alloy is stronger than 6063 and is often used in applications requiring higher strength, such as in the automotive and aerospace industries. The 6040 profile made from 6061 alloy can support heavier loads, making it ideal for demanding applications.

Machinability and Fabrication

Another critical aspect of aluminum profiles is their machinability. The 6040 aluminum extrusion is relatively easy to machine, allowing for the addition of features such as holes, slots, and other modifications.

Compared to other profiles, the 6040's larger size may require more robust machining equipment, but its T-slot design simplifies the assembly process. This ease of fabrication makes the 6040 profile a preferred choice for custom projects where precision and adaptability are essential.

Cost Considerations

Cost is always a factor when selecting materials for a project. Generally, larger profiles like the 6040 aluminum extrusion may have a higher initial cost compared to smaller profiles. However, the long-term benefits, such as durability and reduced maintenance, can offset these initial expenses.

When comparing costs, it is essential to consider the entire project lifecycle, including fabrication, assembly, and potential modifications. The versatility of the 6040 profile can lead to cost savings in assembly and integration, making it a cost-effective choice for many applications.

Applications of 6040 Aluminum Extrusion

The 6040 aluminum extrusion is widely used in various industries due to its unique properties. Some common applications include:

- Modular Workstations: The 6040 profile is often used to create adjustable workstations in manufacturing and assembly environments. Its T-slot design allows for easy reconfiguration as needs change.

- Robotics and Automation: In robotics, the 6040 profile provides a sturdy framework for building robotic arms and other structures. Its strength and adaptability make it ideal for dynamic environments.

- Display and Signage: The aesthetic appeal of the 6040 aluminum extrusion makes it suitable for creating attractive displays and signage. Its ability to be anodized or painted enhances its visual appeal.

- Enclosures and Frames: The 6040 profile is commonly used to construct enclosures for electronic equipment, providing protection while allowing for ventilation and access.

- Industrial Racking Systems: The 6040 profile is also utilized in the construction of industrial racking systems, where its strength and modularity allow for efficient storage solutions.

Advantages of 6040 Aluminum Extrusion

1. Lightweight: Aluminum is known for its lightweight properties, making the 6040 profile easy to handle and transport.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion. This property is particularly beneficial in outdoor applications.

3. Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice. The 6040 profile can be reused or recycled at the end of its life cycle.

4. Aesthetic Flexibility: The 6040 profile can be finished in various ways, including anodizing and powder coating, allowing for customization to match specific design requirements.

5. Ease of Assembly: The T-slot design simplifies the assembly process, enabling quick and efficient construction of complex structures.

6. Thermal Conductivity: Aluminum has excellent thermal conductivity, making the 6040 profile suitable for applications where heat dissipation is essential, such as in heat sinks for electronic devices.

7. Non-Magnetic Properties: Aluminum is non-magnetic, which is advantageous in applications where magnetic interference must be minimized, such as in certain electronic and medical devices.

Limitations of 6040 Aluminum Extrusion

While the 6040 aluminum extrusion has many advantages, it also has some limitations:

1. Cost: As mentioned earlier, the initial cost of larger profiles can be higher than smaller alternatives.

2. Weight: Although aluminum is lightweight, larger profiles like the 6040 can still be heavier than smaller profiles, which may be a consideration in weight-sensitive applications.

3. Machining Requirements: While the 6040 profile is easy to machine, it may require specialized equipment for precise modifications, which can increase fabrication costs.

4. Thermal Expansion: Aluminum has a higher coefficient of thermal expansion compared to other materials, which can lead to dimensional changes in applications subjected to significant temperature fluctuations.

5. Limited Strength in Extreme Conditions: While the 6040 profile is strong, it may not perform as well as steel profiles in extreme load-bearing applications or environments with high stress.

Conclusion

In conclusion, the 6040 aluminum extrusion offers a unique combination of strength, versatility, and ease of use, making it an excellent choice for various applications. When compared to other aluminum profiles, its dimensions and T-slot design provide distinct advantages in modular construction and assembly.

While there are some limitations, the benefits of using the 6040 profile often outweigh the drawbacks, particularly in applications requiring robust and adaptable structures. As industries continue to evolve, the demand for versatile materials like the 6040 aluminum extrusion will likely grow, solidifying its place in modern manufacturing and construction.

Frequently Asked Questions

1. What are the main uses of 6040 aluminum extrusion?

The 6040 aluminum extrusion is commonly used in modular workstations, robotics, display systems, and enclosures for electronic equipment.

2. How does the strength of 6040 aluminum extrusion compare to smaller profiles?

The 6040 profile generally offers greater strength and load-bearing capacity compared to smaller profiles like 2020 and 3030 due to its larger dimensions and the alloys used.

3. Is 6040 aluminum extrusion easy to machine?

Yes, the 6040 aluminum extrusion is relatively easy to machine, allowing for modifications such as drilling and cutting, although it may require specialized equipment for precise work.

4. What are the environmental benefits of using aluminum extrusion?

Aluminum is highly recyclable, and its natural corrosion resistance reduces the need for protective coatings, making it an environmentally friendly choice.

5. Can 6040 aluminum extrusion be customized?

Yes, the 6040 profile can be finished in various ways, including anodizing and powder coating, allowing for aesthetic customization to meet specific design needs.