Content Menu

● Understanding Aluminum Extrusion

● The 45x45 Aluminum Extrusion Profile

>> Key Features of 45x45 Aluminum Extrusion

● Comparing 45x45 Aluminum Extrusion to Other Sizes

>> Strength and Load-Bearing Capacity

>> Weight Considerations

>> Application Suitability

● Advantages of Using 45x45 Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What are the common applications for 45x45 aluminum extrusion?

>> 2. How does the weight of 45x45 aluminum extrusion compare to smaller profiles?

>> 3. Can 45x45 aluminum extrusion be used for outdoor applications?

>> 4. Is the 45x45 aluminum extrusion easy to assemble?

>> 5. What are the advantages of using aluminum extrusion over other materials?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This process is widely used in various industries due to the material's lightweight, strength, and versatility. Among the many sizes available, the 45x45 mm aluminum extrusion profile is particularly popular. This article will explore how the 45x45 aluminum extrusion compares to other sizes, discussing its applications, advantages, and considerations for use.

Understanding Aluminum Extrusion

Before diving into the specifics of the 45x45 profile, it's essential to understand what aluminum extrusion entails. The extrusion process involves forcing aluminum alloy through a die to create a continuous profile. This method allows for complex shapes and designs, making it ideal for various applications, from structural components to decorative elements.

The importance of profile size cannot be overstated. The size of an aluminum extrusion profile significantly impacts its strength, weight, and suitability for different applications. Common sizes include 20x20 mm, 30x30 mm, 40x40 mm, and 45x45 mm, among others. Each size has its unique characteristics, making it suitable for specific uses.

The 45x45 Aluminum Extrusion Profile

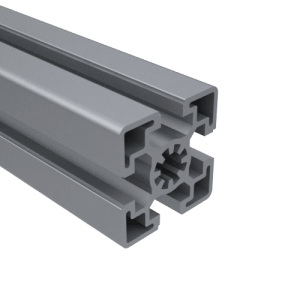

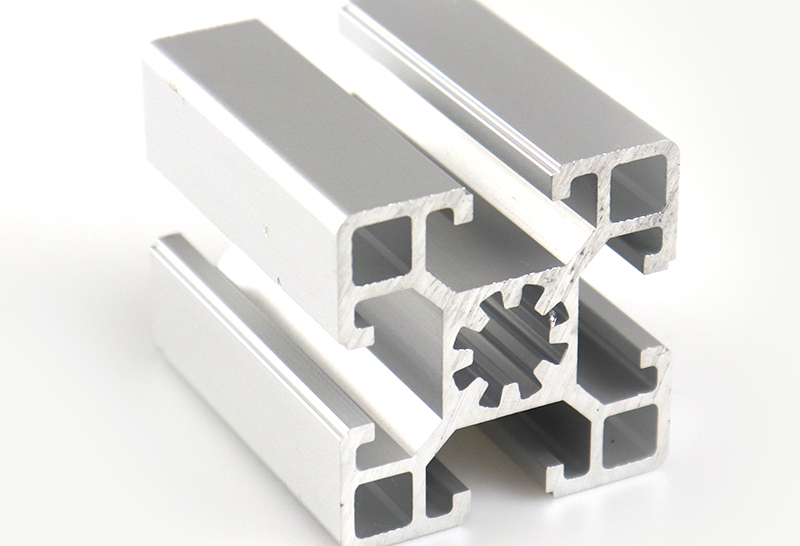

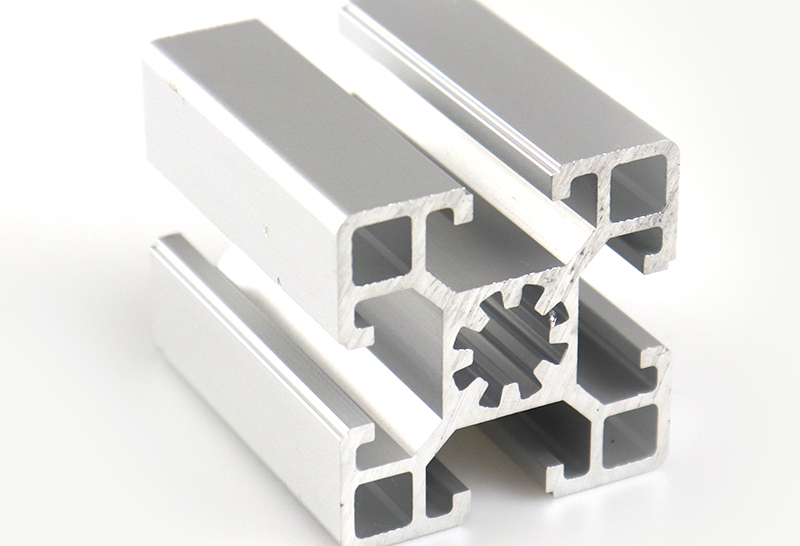

The 45x45 mm aluminum extrusion profile is characterized by its square shape and is part of the T-slot family of extrusions. This profile is particularly favored in modular construction, robotics, and automation due to its robust design and ease of assembly.

Key Features of 45x45 Aluminum Extrusion

1. Versatility: The 45x45 profile can be used in various applications, including framing, supports, and enclosures. Its T-slot design allows for easy attachment of components, making it ideal for custom builds.

2. Strength: The square shape provides excellent structural integrity, allowing it to bear significant loads. This makes it suitable for both lightweight and heavy-duty applications.

3. Ease of Assembly: The T-slot design enables quick and straightforward assembly without the need for specialized tools. This feature is particularly beneficial for prototyping and temporary structures.

4. Aesthetic Appeal: The clean lines and modern look of aluminum extrusions make them a popular choice for visible structures, such as display cases and furniture.

Comparing 45x45 Aluminum Extrusion to Other Sizes

When comparing the 45x45 profile to other sizes, several factors come into play, including strength, weight, and application suitability.

Strength and Load-Bearing Capacity

The strength of an aluminum extrusion profile is primarily determined by its cross-sectional area and shape. The 45x45 profile offers a good balance between strength and weight, making it suitable for various applications.

- 20x20 mm Profile: While lighter and easier to handle, the 20x20 profile may not provide the same load-bearing capacity as the 45x45 profile. It is often used in smaller, less demanding applications.

- 30x30 mm Profile: The 30x30 profile offers a middle ground, providing more strength than the 20x20 but still falling short of the 45x45 in terms of load capacity.

- 40x40 mm Profile: The 40x40 profile is stronger than the 30x30 but may still not match the versatility and strength of the 45x45 profile, especially in larger structures.

- 60x60 mm Profile: While the 60x60 profile offers superior strength, it is also heavier and may not be necessary for applications where the 45x45 profile suffices.

Weight Considerations

Weight is a crucial factor in many applications, especially in industries like aerospace and automotive, where reducing weight can lead to significant efficiency gains.

- The 45x45 profile, while heavier than smaller profiles, provides a good strength-to-weight ratio. This makes it suitable for applications where both strength and weight are critical.

- Smaller profiles like 20x20 and 30x30 are lighter and easier to handle, making them ideal for portable applications or where weight savings are paramount.

Application Suitability

The choice of aluminum extrusion size often depends on the specific application requirements.

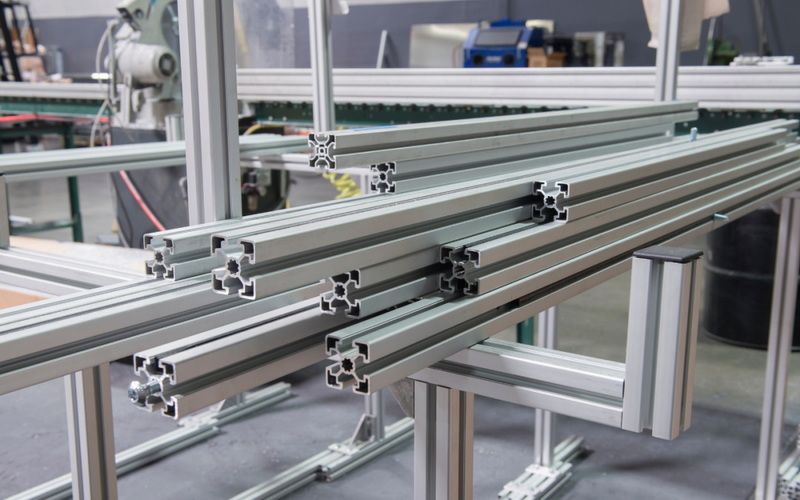

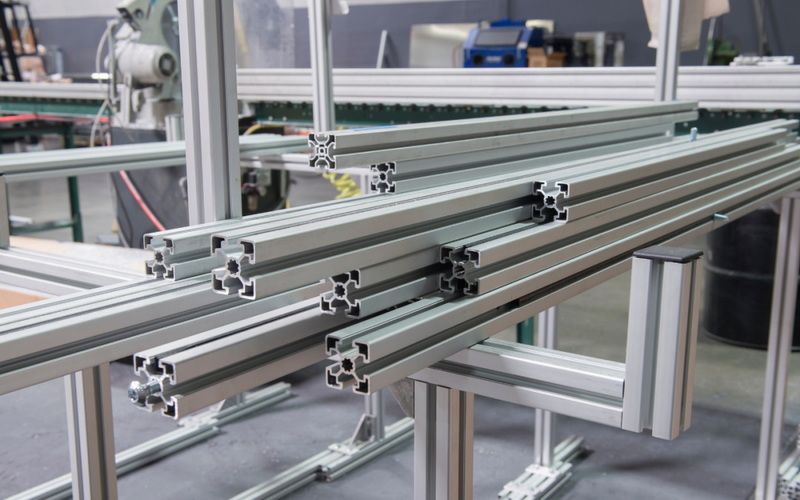

- 45x45 mm Profile: Ideal for structural frames, machine guards, and workstations. Its versatility allows it to be used in both permanent and temporary structures.

- 20x20 mm Profile: Best suited for lightweight applications such as small enclosures, brackets, and supports.

- 30x30 mm Profile: Commonly used in medium-duty applications, including furniture and display stands.

- 40x40 mm Profile: Suitable for heavier applications, such as industrial machinery and larger frames.

- 60x60 mm Profile: Often used in heavy-duty applications where maximum strength is required, such as in construction and large machinery.

Advantages of Using 45x45 Aluminum Extrusion

1. Modularity: The T-slot design allows for easy reconfiguration and expansion of structures, making it ideal for evolving projects.

2. Cost-Effectiveness: While the initial cost may be higher than smaller profiles, the durability and versatility of the 45x45 profile can lead to long-term savings.

3. Sustainability: Aluminum is a recyclable material, making it an environmentally friendly choice for construction and manufacturing.

4. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion and suitable for outdoor applications.

5. Aesthetic Flexibility: The sleek appearance of aluminum extrusions allows them to be used in both functional and decorative applications, enhancing the overall design of a project.

Conclusion

In conclusion, the 45x45 aluminum extrusion profile stands out for its versatility, strength, and ease of use. While it may not be the lightest option available, its robust design makes it suitable for a wide range of applications. When comparing it to other sizes, the 45x45 profile offers a balanced approach, providing sufficient strength for demanding applications while remaining manageable in weight.

As industries continue to evolve, the demand for efficient and adaptable materials like aluminum extrusion will only grow. The 45x45 profile, with its unique characteristics, will undoubtedly remain a popular choice among engineers, designers, and manufacturers.

Frequently Asked Questions

1. What are the common applications for 45x45 aluminum extrusion?

The 45x45 aluminum extrusion is commonly used in structural frames, machine guards, workstations, and modular systems.

2. How does the weight of 45x45 aluminum extrusion compare to smaller profiles?

The 45x45 profile is heavier than smaller profiles like 20x20 and 30x30, but it offers a better strength-to-weight ratio for demanding applications.

3. Can 45x45 aluminum extrusion be used for outdoor applications?

Yes, aluminum is naturally corrosion-resistant, making the 45x45 profile suitable for outdoor use.

4. Is the 45x45 aluminum extrusion easy to assemble?

Yes, the T-slot design allows for quick and easy assembly without the need for specialized tools.

5. What are the advantages of using aluminum extrusion over other materials?

Aluminum extrusion offers a lightweight, strong, and corrosion-resistant option that is also recyclable, making it an environmentally friendly choice for various applications.