Content Menu

● Understanding Aluminum Extrusion

● The 40120 Aluminum Extrusion Profile

>> Key Features of 40120 Aluminum Extrusion

● Comparing 40120 Aluminum Extrusion to Other Profiles

>> Size and Dimensions

>> Strength and Load-Bearing Capacity

>> Weight Considerations

● Applications of 40120 Aluminum Extrusion

>> Advantages of Using 40120 Aluminum Extrusion

● Visualizing the Comparison

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary use of 40120 aluminum extrusion?

>> 2. How does the 40120 profile compare to the 4040 profile?

>> 3. Is the 40120 aluminum extrusion easy to assemble?

>> 4. Can the 40120 profile be used outdoors?

>> 5. What are the environmental benefits of using aluminum extrusions?

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This process is widely used in various industries due to the material's lightweight, strength, and corrosion resistance. Among the many profiles available, the 40120 aluminum extrusion stands out for its unique characteristics and applications. In this article, we will explore how the 40120 aluminum extrusion compares to other aluminum profiles, discussing its features, benefits, and applications, while also providing visual aids to enhance understanding.

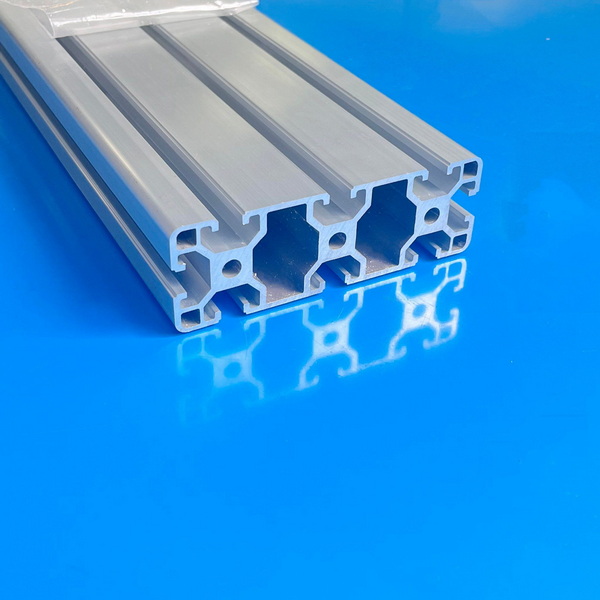

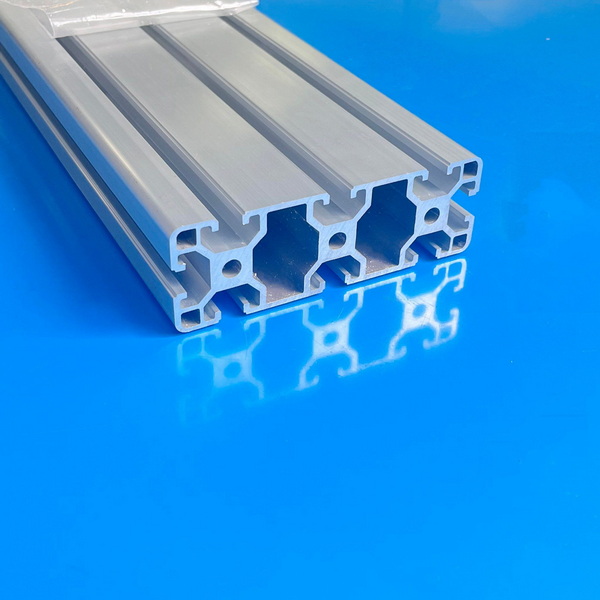

The 40120 Aluminum Extrusion Profile

The 40120 aluminum extrusion profile is part of the 40 series of aluminum extrusions, which are characterized by their T-slot design. This profile measures 40mm by 20mm, making it suitable for a wide range of applications. The T-slot design allows for easy assembly and disassembly, making it ideal for modular construction and custom projects.

Key Features of 40120 Aluminum Extrusion

1. Versatility: The 40120 profile can be used in various applications, including framing, machine guards, and workstations. Its modular design allows for easy customization and adaptability.

2. Strength: Aluminum is known for its strength-to-weight ratio. The 40120 profile is robust enough to support heavy loads while remaining lightweight, making it an excellent choice for structural applications.

3. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps prevent corrosion. This property makes the 40120 profile suitable for both indoor and outdoor use.

4. Ease of Assembly: The T-slot design allows for quick and easy assembly using standard fasteners. This feature is particularly beneficial for projects that require frequent modifications or adjustments.

5. Aesthetic Appeal: The sleek appearance of aluminum profiles adds a modern touch to any project. The 40120 profile can be anodized or powder-coated to enhance its visual appeal and durability.

Comparing 40120 Aluminum Extrusion to Other Profiles

When comparing the 40120 aluminum extrusion to other profiles, several factors come into play, including size, strength, weight, and application suitability.

Size and Dimensions

The 40120 profile is part of the 40mm series, which includes various other profiles such as 4040, 4045, and 4080. Each of these profiles has different dimensions and load-bearing capacities. For instance, the 4040 profile measures 40mm by 40mm, providing a square shape that may be more suitable for certain applications requiring uniformity in all directions. The 40120 profile, with its rectangular shape, offers a different set of advantages, particularly in applications where space constraints are a concern.

Strength and Load-Bearing Capacity

The load-bearing capacity of aluminum profiles varies based on their dimensions and design. The 40120 profile is designed to handle moderate loads, making it suitable for applications such as workstations and display stands. In contrast, larger profiles like the 4080 can support heavier loads, making them ideal for structural applications in construction or heavy machinery. Understanding the specific load requirements of a project is crucial when selecting the appropriate aluminum profile.

Weight Considerations

Weight is a crucial factor in many applications, especially in industries like aerospace and automotive. The 40120 profile offers a lightweight solution without compromising strength. However, for applications where weight is less of a concern, larger profiles may be preferred for their increased load-bearing capabilities. The choice between a lighter profile like the 40120 and a heavier one depends on the specific requirements of the project, including the need for mobility and ease of installation.

Applications of 40120 Aluminum Extrusion

The versatility of the 40120 aluminum extrusion profile allows it to be used in various applications across different industries. Here are some common uses:

1. Modular Workstations: The 40120 profile is often used to create custom workstations in manufacturing and assembly environments. Its T-slot design allows for easy integration of accessories such as shelves, tool holders, and lighting. This adaptability makes it a favorite among manufacturers looking to optimize their workspace.

2. Machine Guards: The strength and durability of the 40120 profile make it an excellent choice for machine guards, providing safety and protection in industrial settings. The ability to customize the height and width of the guards ensures that they can be tailored to fit specific machinery, enhancing workplace safety.

3. Display Stands: Retail environments often utilize the 40120 profile to create attractive and functional display stands. Its aesthetic appeal and modularity allow for easy customization to fit various product displays. Retailers can quickly change the layout of their displays, keeping the shopping experience fresh and engaging for customers.

4. Automated Systems: In automation and robotics, the 40120 profile is used to construct frames and supports for robotic arms and conveyor systems, providing a lightweight yet sturdy structure. The ability to easily modify the frame design allows for quick adjustments as technology evolves.

5. Furniture Design: The modern look of aluminum profiles makes them popular in furniture design. The 40120 profile can be used to create stylish and functional furniture pieces, such as tables and shelving units. Designers appreciate the flexibility of aluminum, allowing them to create unique pieces that stand out in any environment.

Advantages of Using 40120 Aluminum Extrusion

1. Cost-Effectiveness: The 40120 profile is often more cost-effective than larger profiles, making it an attractive option for budget-conscious projects. Its affordability does not compromise quality, making it a smart choice for many applications.

2. Customization: The modular nature of the 40120 profile allows for easy customization, enabling users to create unique solutions tailored to their specific needs. This flexibility is particularly beneficial in industries where requirements frequently change.

3. Sustainability: Aluminum is a recyclable material, making the use of aluminum extrusions an environmentally friendly choice. The 40120 profile can be recycled at the end of its life cycle, reducing waste. This sustainability aspect is increasingly important to consumers and businesses alike.

4. Low Maintenance: The corrosion resistance of aluminum means that the 40120 profile requires minimal maintenance, making it a practical choice for long-term use. This low maintenance requirement translates to cost savings over time.

5. Thermal Conductivity: Aluminum has excellent thermal conductivity, making the 40120 profile suitable for applications where heat dissipation is essential. This property is particularly valuable in electronic enclosures and heat sinks.

Visualizing the Comparison

To better understand the differences between the 40120 aluminum extrusion and other profiles, consider the following visual aids:

- Profile Comparison Chart: A chart comparing the dimensions, load capacities, and typical applications of various aluminum profiles, including 40120, 4040, and 4080.

- Assembly Diagrams: Diagrams illustrating how to assemble structures using the 40120 profile, showcasing its versatility in different configurations.

- Application Photos: Images of real-world applications of the 40120 profile, such as workstations, machine guards, and display stands, highlighting its functionality and aesthetic appeal.

Conclusion

In conclusion, the 40120 aluminum extrusion profile offers a unique combination of versatility, strength, and aesthetic appeal, making it an excellent choice for a wide range of applications. While it may not be suitable for every project, its advantages make it a popular option in various industries. By understanding how the 40120 profile compares to other aluminum profiles, manufacturers and designers can make informed decisions that best suit their needs.

Frequently Asked Questions

1. What is the primary use of 40120 aluminum extrusion?

- The 40120 aluminum extrusion is primarily used in modular workstations, machine guards, display stands, and various structural applications due to its strength and versatility.

2. How does the 40120 profile compare to the 4040 profile?

- The 40120 profile measures 40mm by 20mm, while the 4040 profile measures 40mm by 40mm. The 4040 profile offers a square shape, which may provide more uniform load distribution in certain applications.

3. Is the 40120 aluminum extrusion easy to assemble?

- Yes, the T-slot design of the 40120 profile allows for quick and easy assembly using standard fasteners, making it ideal for projects that require frequent modifications.

4. Can the 40120 profile be used outdoors?

- Yes, the corrosion resistance of aluminum makes the 40120 profile suitable for outdoor use, provided it is properly finished or coated to enhance durability.

5. What are the environmental benefits of using aluminum extrusions?

- Aluminum is a recyclable material, and using aluminum extrusions like the 40120 profile contributes to sustainability by reducing waste and promoting recycling at the end of its life cycle.