Content Menu

● Understanding Aluminum Extrusions

● The 30 x 30 Aluminum Extrusion Profile

● Applications of 30 x 30 Aluminum Extrusion

● Comparing 30 x 30 Aluminum Extrusion to Other Sizes

>> Strength and Load-Bearing Capacity

>> Weight Considerations

>> Versatility and Adaptability

● Cost Considerations

● Visualizing the Differences

● Real-World Examples

>> Case Study: Automated Assembly Line

>> Case Study: Retail Display

● Environmental Considerations

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using 30 x 30 aluminum extrusion?

>> 2. In what applications is 30 x 30 aluminum extrusion typically used?

>> 3. How does the load-bearing capacity of 30 x 30 compare to larger profiles?

>> 4. Is 30 x 30 aluminum extrusion more cost-effective than larger profiles?

>> 5. Can 30 x 30 aluminum extrusion be easily modified or expanded?

Aluminum extrusions are a fundamental component in various industries, providing structural support and versatility in design. Among the many sizes available, the 30 x 30 mm aluminum extrusion profile stands out due to its balance of strength, weight, and adaptability. This article explores how the 30 x 30 aluminum extrusion compares to other sizes, examining its applications, advantages, and the contexts in which it excels.

Understanding Aluminum Extrusions

Aluminum extrusion is a process that involves forcing aluminum alloy through a die to create a specific cross-sectional shape. This method allows for the production of complex profiles that can be used in a wide range of applications, from construction to manufacturing machinery. The resulting extrusions are lightweight, corrosion-resistant, and can be easily machined or assembled.

The 30 x 30 Aluminum Extrusion Profile

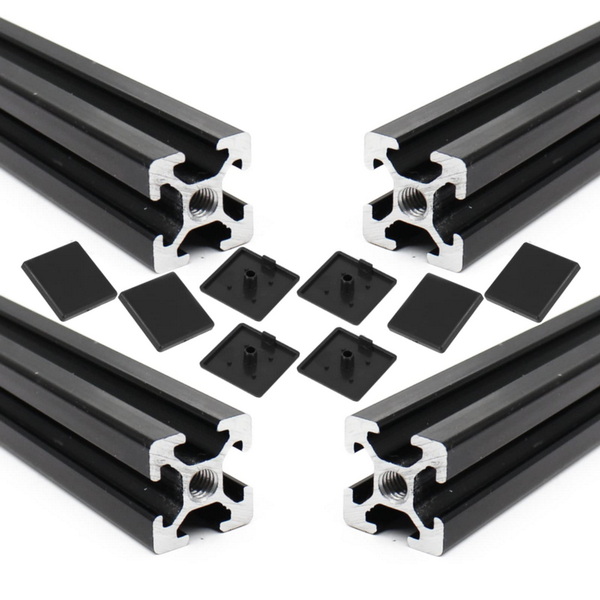

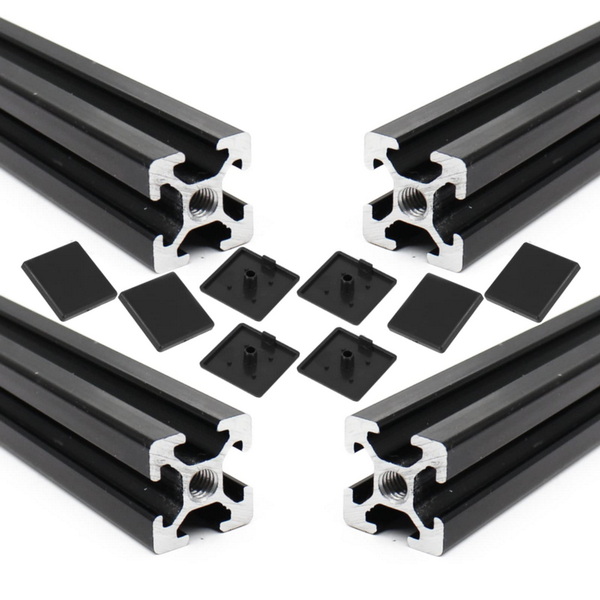

The 30 x 30 mm aluminum extrusion profile is part of the 30 series, which is characterized by its square shape and T-slot design. This profile features four open T-slots on each side, allowing for easy attachment of various components, such as brackets, connectors, and fasteners. The dimensions make it suitable for medium-duty applications, providing a good balance between strength and weight.

Applications of 30 x 30 Aluminum Extrusion

The versatility of the 30 x 30 aluminum extrusion makes it ideal for a variety of applications, including:

- Frameworks and Structures: It is commonly used in building frames for enclosures, workstations, and machine guards.

- Automated Systems: The profile is often utilized in the construction of conveyor systems and robotic arms due to its lightweight nature and strength.

- Furniture Design: Many modern furniture designs incorporate aluminum extrusions for their aesthetic appeal and structural integrity.

- Display Racks: Retail environments frequently use 30 x 30 profiles for creating display stands and shelving units.

Comparing 30 x 30 Aluminum Extrusion to Other Sizes

When comparing the 30 x 30 aluminum extrusion to other sizes, several factors come into play, including strength, weight, and application suitability.

Strength and Load-Bearing Capacity

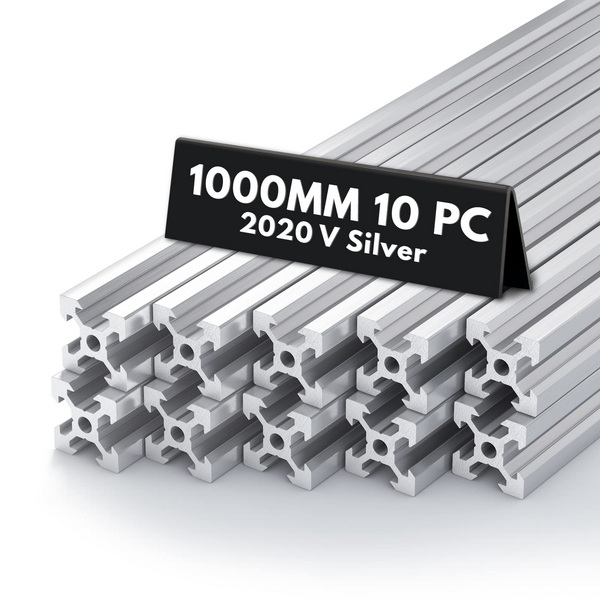

One of the primary considerations when selecting an aluminum extrusion profile is its strength. The 30 x 30 profile offers a good load-bearing capacity for medium-duty applications. However, larger profiles, such as 40 x 40 mm or 45 x 45 mm, provide increased strength and rigidity, making them more suitable for heavy-duty applications. The choice of profile size often depends on the specific requirements of the project, including the expected loads and environmental conditions.

Weight Considerations

Weight is another critical factor in the selection of aluminum extrusions. The 30 x 30 profile is lightweight, making it easier to handle and install compared to larger profiles. This characteristic is particularly beneficial in applications where weight savings are essential, such as in portable structures or mobile equipment. The reduced weight can also lead to lower shipping costs and easier transportation, which is a significant advantage in many industries.

Versatility and Adaptability

The T-slot design of the 30 x 30 aluminum extrusion allows for a high degree of versatility. It can be easily modified or expanded upon, accommodating changes in design or function. In contrast, larger profiles may offer more strength but can be less adaptable due to their size and weight. The ability to quickly reconfigure a structure using the 30 x 30 profile can save time and resources during the design and assembly phases.

Cost Considerations

Cost is always a factor in material selection. Generally, the 30 x 30 aluminum extrusion is more cost-effective than larger profiles, making it an attractive option for budget-conscious projects. However, the total cost will also depend on the specific application and the required load-bearing capacity. In some cases, investing in a larger profile may be justified if the application demands higher strength and durability.

Visualizing the Differences

To better understand the differences between the 30 x 30 aluminum extrusion and other sizes, consider the various applications and configurations. For instance, in a manufacturing setting, the 30 x 30 profile might be used for lightweight frames, while a 40 x 40 profile could be employed for heavy-duty machinery supports. This flexibility allows engineers and designers to choose the most appropriate profile for their specific needs.

Real-World Examples

Case Study: Automated Assembly Line

In an automated assembly line, engineers opted for the 30 x 30 aluminum extrusion to construct the framework for the conveyor system. The lightweight nature of the profile allowed for easy installation and modification as the production requirements evolved. However, for the load-bearing sections of the assembly line, they utilized 40 x 40 mm profiles to ensure adequate strength and stability. This combination of profiles optimized both performance and cost, demonstrating the importance of selecting the right size for each application.

Case Study: Retail Display

A retail store designed a new display using 30 x 30 aluminum extrusions. The T-slot design enabled quick assembly and reconfiguration of the display as new products were introduced. The lightweight profile made it easy to move and adjust the display without requiring extensive labor or equipment. This adaptability not only enhanced the store's visual merchandising but also allowed for efficient use of space.

Environmental Considerations

In today's world, sustainability is a crucial factor in material selection. Aluminum is a highly recyclable material, and using aluminum extrusions can contribute to a more sustainable manufacturing process. The 30 x 30 aluminum extrusion profile, like other aluminum products, can be recycled at the end of its life cycle, reducing waste and conserving resources. Additionally, the lightweight nature of aluminum can lead to lower energy consumption during transportation, further enhancing its environmental benefits.

Conclusion

The 30 x 30 aluminum extrusion profile is a versatile and cost-effective option for a wide range of applications. While it offers a good balance of strength and weight, it is essential to consider the specific requirements of each project. Larger profiles may be necessary for heavy-duty applications, while the 30 x 30 profile excels in medium-duty scenarios where adaptability and ease of use are paramount. By understanding the strengths and limitations of different aluminum extrusion sizes, designers and engineers can make informed decisions that optimize performance and cost-effectiveness.

Frequently Asked Questions

1. What are the main advantages of using 30 x 30 aluminum extrusion?

The main advantages include its lightweight nature, versatility, ease of assembly, and cost-effectiveness for medium-duty applications.

2. In what applications is 30 x 30 aluminum extrusion typically used?

It is commonly used in frameworks, automated systems, furniture design, and display racks.

3. How does the load-bearing capacity of 30 x 30 compare to larger profiles?

The 30 x 30 profile has a good load-bearing capacity for medium-duty applications, but larger profiles like 40 x 40 mm offer increased strength for heavy-duty applications.

4. Is 30 x 30 aluminum extrusion more cost-effective than larger profiles?

Generally, yes. The 30 x 30 profile is more cost-effective, making it suitable for budget-conscious projects.

5. Can 30 x 30 aluminum extrusion be easily modified or expanded?

Yes, the T-slot design allows for easy modifications and expansions, accommodating changes in design or function.