Content Menu

● Understanding Aluminum Extrusions

● The 20x40 Aluminum Extrusion Profile

● Comparing 20x40 Aluminum Extrusion to Other Sizes

>> Strength and Load-Bearing Capacity

>> Weight Considerations

>> Versatility and Applications

>> Cost Considerations

● Additional Benefits of 20x40 Aluminum Extrusion

>> Ease of Assembly

>> Aesthetic Appeal

>> Environmental Considerations

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using 20x40 aluminum extrusion?

>> 2. Can 20x40 aluminum extrusion be used for outdoor applications?

>> 3. How do I cut 20x40 aluminum extrusion?

>> 4. What types of connectors can be used with 20x40 aluminum extrusion?

>> 5. Is 20x40 aluminum extrusion suitable for heavy-duty applications?

Aluminum extrusions are widely used in various industries due to their lightweight, strength, and versatility. Among the many sizes available, the 20x40 aluminum extrusion profile stands out for its unique balance of structural integrity and adaptability. This article will explore how the 20x40 aluminum extrusion compares to other sizes, discussing its applications, advantages, and the contexts in which it excels.

Understanding Aluminum Extrusions

Aluminum extrusion is a process that involves shaping aluminum alloy by forcing it through a die. This method allows for the creation of complex shapes and profiles that can be used in a variety of applications, from construction to manufacturing. The dimensions of these extrusions are typically described in millimeters, with the first number representing the width and the second the height. For instance, a 20x40 aluminum extrusion has a width of 20 mm and a height of 40 mm.

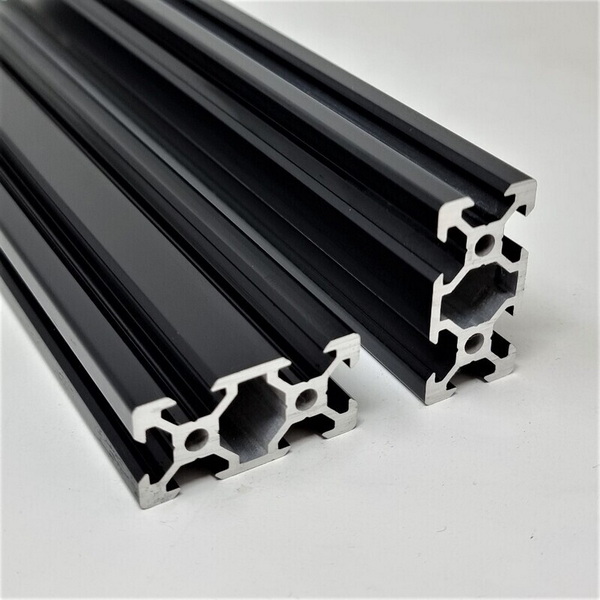

The 20x40 Aluminum Extrusion Profile

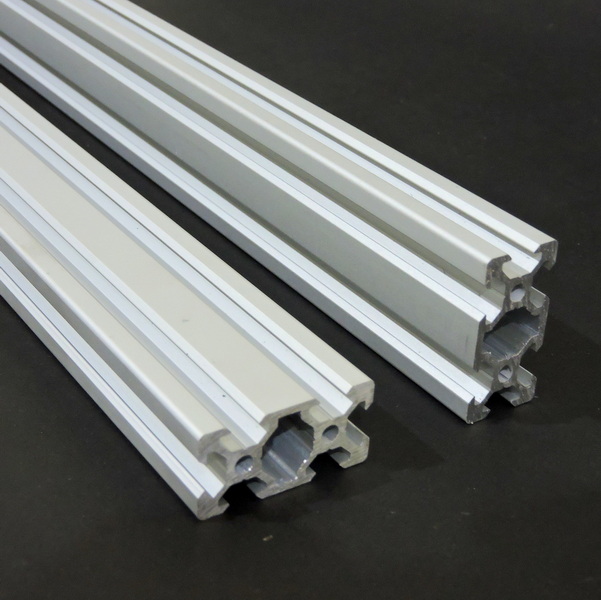

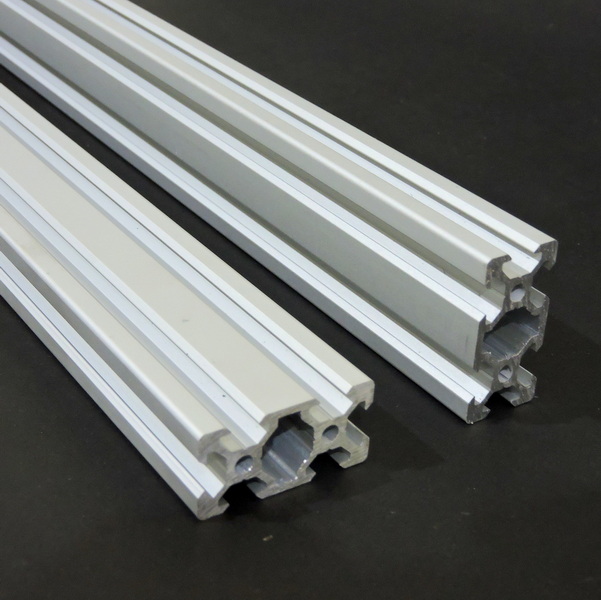

The 20x40 aluminum extrusion profile is part of the T-slot family, which features grooves along its length. These grooves allow for easy assembly and integration with other components, making it a popular choice for building frames, supports, and enclosures. The profile's dimensions provide a good balance between strength and weight, making it suitable for various applications.

Comparing 20x40 Aluminum Extrusion to Other Sizes

When comparing the 20x40 aluminum extrusion to other sizes, several factors come into play, including strength, weight, versatility, and cost. Here, we will compare it to some common sizes: 20x20, 30x30, and 40x40 aluminum extrusions.

Strength and Load-Bearing Capacity

One of the primary considerations when choosing an aluminum extrusion profile is its strength. The 20x40 profile offers a higher load-bearing capacity than the 20x20 profile due to its larger cross-sectional area. This makes it suitable for applications that require more structural support, such as frames for machinery or heavy equipment.

In contrast, while the 30x30 and 40x40 profiles provide even greater strength, they also come with increased weight. The choice between these profiles often depends on the specific requirements of the project. For instance, if weight is a critical factor, the 20x40 profile may be the best option, as it provides a good compromise between strength and weight.

Weight Considerations

Weight is another crucial factor in the selection of aluminum extrusions. The 20x40 profile is lighter than the 30x30 and 40x40 profiles, making it easier to handle and install. This is particularly important in applications where mobility is required, such as in portable structures or equipment.

For example, in the construction of a mobile workstation, using a 20x40 aluminum extrusion can significantly reduce the overall weight of the structure, making it easier to transport and set up.

Versatility and Applications

The versatility of the 20x40 aluminum extrusion is one of its most significant advantages. It can be used in a wide range of applications, including:

- Industrial Automation: The 20x40 profile is commonly used in the construction of frames for automated machinery and conveyor systems.

- Robotics: Its strength and lightweight nature make it ideal for building robotic arms and other components.

- Furniture: The profile can be used to create modern furniture designs, such as tables and shelving units.

- Enclosures: It is often used to build protective enclosures for sensitive equipment.

In comparison, while the 30x30 and 40x40 profiles are also versatile, they are often used in applications that require more robust structures, such as heavy-duty machinery frames or large-scale construction projects.

Cost Considerations

Cost is always a factor in material selection. Generally, the larger the profile, the higher the cost. The 20x40 aluminum extrusion is typically more affordable than the 30x30 and 40x40 profiles, making it an attractive option for budget-conscious projects.

For small to medium-sized projects, the 20x40 profile provides an excellent balance of performance and cost, allowing for efficient use of resources without compromising on quality.

Additional Benefits of 20x40 Aluminum Extrusion

Ease of Assembly

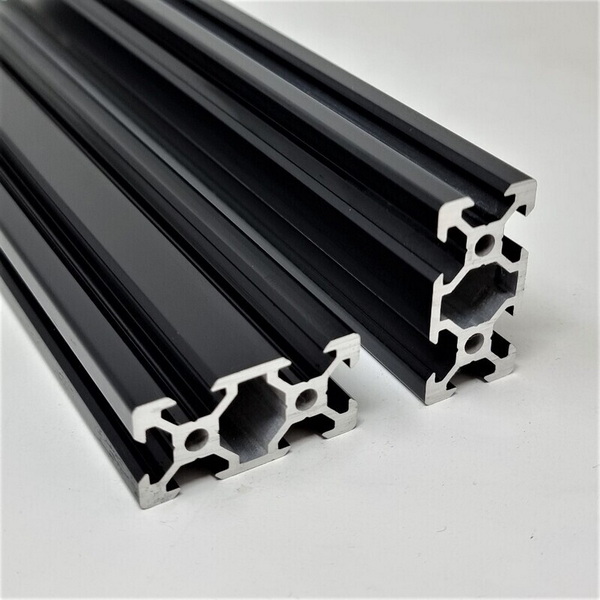

One of the standout features of the 20x40 aluminum extrusion is its ease of assembly. The T-slot design allows for quick and straightforward connections between different components. This feature is particularly beneficial in environments where modifications or adjustments are frequently required. Users can easily add or remove components without the need for specialized tools, making it a flexible solution for evolving project needs.

Aesthetic Appeal

In addition to its functional benefits, the 20x40 aluminum extrusion also offers aesthetic advantages. The clean lines and modern appearance of aluminum profiles make them suitable for visible applications, such as furniture and display cases. The ability to anodize or powder-coat the aluminum further enhances its visual appeal, allowing for a variety of finishes that can match different design themes.

Environmental Considerations

Aluminum is a highly recyclable material, making it an environmentally friendly choice. The production of aluminum extrusions typically involves less energy compared to other materials, and the ability to recycle aluminum without losing its properties contributes to sustainability efforts. By choosing 20x40 aluminum extrusions, companies can reduce their environmental footprint while still achieving high-performance results.

Conclusion

In summary, the 20x40 aluminum extrusion profile offers a unique combination of strength, lightweight design, versatility, and cost-effectiveness. When compared to other sizes, such as 20x20, 30x30, and 40x40, it stands out as an ideal choice for a wide range of applications. Its ability to support significant loads while remaining lightweight makes it particularly valuable in industries such as automation, robotics, and furniture design.

As you consider your next project, think about the specific requirements you have in terms of strength, weight, versatility, and budget. The 20x40 aluminum extrusion may just be the perfect fit for your needs.

Frequently Asked Questions

1. What are the main advantages of using 20x40 aluminum extrusion?

The main advantages include its lightweight nature, high strength-to-weight ratio, versatility in applications, and cost-effectiveness.

2. Can 20x40 aluminum extrusion be used for outdoor applications?

Yes, aluminum is naturally resistant to corrosion, making it suitable for outdoor use. However, it is advisable to use anodized or powder-coated finishes for added protection.

3. How do I cut 20x40 aluminum extrusion?

You can cut aluminum extrusion using a miter saw with a fine-toothed blade, a band saw, or a hacksaw. Ensure to measure accurately and secure the profile before cutting.

4. What types of connectors can be used with 20x40 aluminum extrusion?

Various connectors, such as corner brackets, T-nuts, and bolts, can be used to join 20x40 aluminum extrusions, allowing for flexible assembly options.

5. Is 20x40 aluminum extrusion suitable for heavy-duty applications?

While it is strong and suitable for many applications, for extremely heavy-duty applications, larger profiles like 30x30 or 40x40 may be more appropriate.