Content Menu

● Understanding Screen Aluminum Extrusion

>> Benefits of Using Screen Aluminum Extrusion

● Tools and Materials Needed

● Step-by-Step Installation Process

>> Step 1: Measure and Plan

>> Step 2: Cut the Aluminum Extrusions

>> Step 3: Assemble the Frame

>> Step 4: Attach the Screen Mesh

>> Step 5: Install the Frame

>> Step 6: Finishing Touches

● Tips for Maximum Durability

● Common Applications of Screen Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What type of screen mesh is best for aluminum extrusions?

>> 2. Can I paint aluminum extrusions?

>> 3. How do I maintain my screen aluminum extrusion?

>> 4. Is it possible to install screen aluminum extrusion on uneven surfaces?

>> 5. What tools do I need for installation?

Understanding Screen Aluminum Extrusion

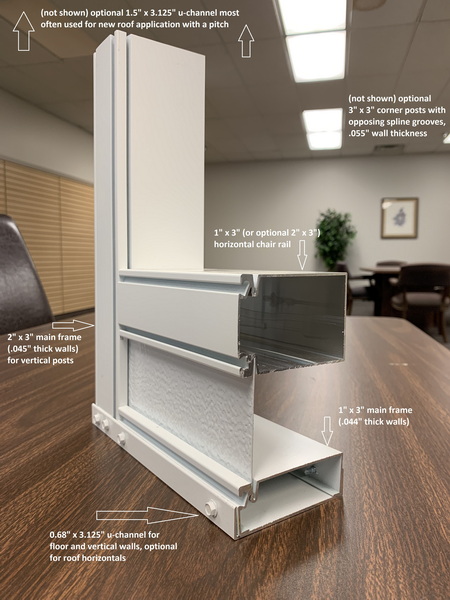

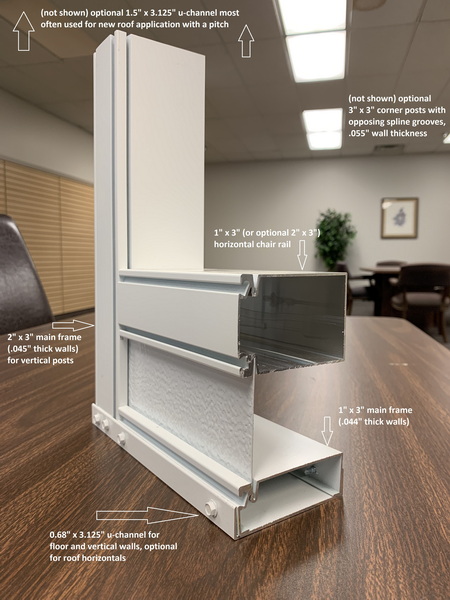

Screen aluminum extrusion refers to the process of shaping aluminum into specific profiles that can be used to create frames for screens. These extrusions are lightweight, resistant to corrosion, and can withstand various weather conditions, making them an ideal choice for outdoor applications. The durability of aluminum extrusions is enhanced by their ability to resist rust and decay, which is particularly important in humid or rainy environments.

Benefits of Using Screen Aluminum Extrusion

1. Durability: Aluminum is known for its strength and longevity. It does not warp, crack, or swell like wood, ensuring that your screen frames will maintain their shape and function over time.

2. Low Maintenance: Unlike wood, which requires regular painting or sealing, aluminum extrusions are easy to clean and maintain. A simple wash with soap and water is often sufficient to keep them looking new.

3. Versatility: Aluminum extrusions can be customized to fit various applications, from window screens to large patio enclosures. They can be painted or anodized to match your home's aesthetic.

4. Ease of Installation: With the right tools and techniques, installing screen aluminum extrusion can be a straightforward DIY project.

Tools and Materials Needed

Before you begin the installation process, gather the following tools and materials:

- Tools:

- Measuring tape

- Miter saw or hacksaw

- Drill and drill bits

- Screwdriver

- Level

- Safety goggles

- Gloves

- Materials:

- Screen aluminum extrusions (frames)

- Screen mesh (fiberglass or aluminum)

- Corner brackets (if needed)

- Screws and fasteners

- Adhesive or sealant (optional)

Step-by-Step Installation Process

Step 1: Measure and Plan

Begin by measuring the area where you plan to install the screen aluminum extrusion. Accurate measurements are crucial for ensuring that your frames fit properly. Consider the following:

- Height and width of the opening

- Any obstructions (like window sills or door frames)

- Desired screen tension and fit

Step 2: Cut the Aluminum Extrusions

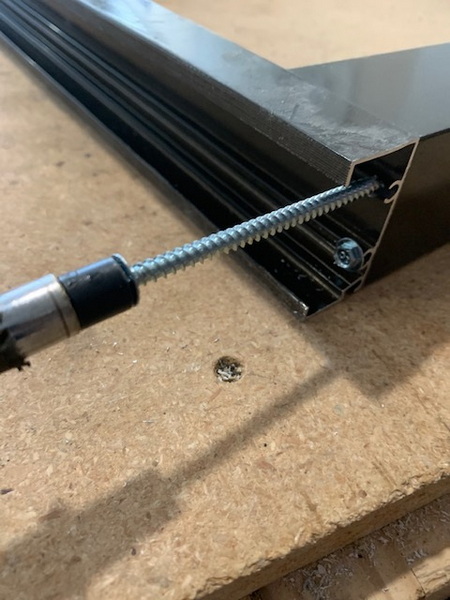

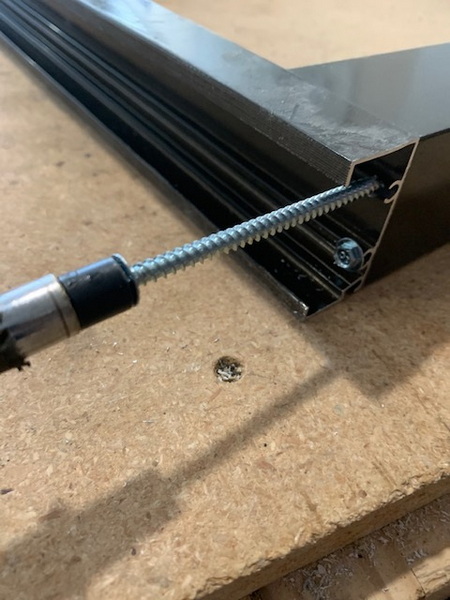

Using a miter saw or hacksaw, cut the aluminum extrusions to the appropriate lengths based on your measurements. Make sure to wear safety goggles and gloves during this process to protect yourself from sharp edges.

Step 3: Assemble the Frame

Once you have cut the extrusions, assemble the frame. If you are using corner brackets, attach them to the corners of the frame using screws. Ensure that the frame is square by measuring the diagonals; they should be equal.

Step 4: Attach the Screen Mesh

Lay the screen mesh over the frame, ensuring that it extends beyond the edges. Secure the mesh to the frame using staples or screen clips. If you are using adhesive, apply it along the edges of the frame before attaching the mesh. Pull the mesh taut to avoid sagging.

Step 5: Install the Frame

With the screen mesh attached, it's time to install the frame. Position the frame in the desired location and use a level to ensure it is straight. Secure the frame to the wall or structure using screws. If you are installing a larger frame, consider adding additional support in the middle to prevent bowing.

Step 6: Finishing Touches

After the frame is securely installed, trim any excess screen mesh and clean up the area. You may choose to apply a sealant around the edges for added protection against moisture.

Tips for Maximum Durability

- Choose Quality Materials: Invest in high-quality aluminum extrusions and screen mesh to ensure longevity. Look for extrusions that are anodized or powder-coated for added protection against the elements.

- Regular Maintenance: Periodically check the frames for any signs of wear or damage. Clean the screens regularly to prevent dirt buildup. If you notice any tears or holes in the mesh, repair them promptly to maintain the integrity of the screen.

- Consider Weather Conditions: If you live in an area with extreme weather, consider additional reinforcements or protective coatings for your aluminum frames. For instance, using a UV-resistant screen mesh can help prevent fading and deterioration from sunlight exposure.

- Proper Installation Techniques: Ensure that you follow the installation instructions carefully. Misalignment or improper fastening can lead to structural weaknesses that may compromise the durability of the screen.

- Use of Sealants: Applying a high-quality sealant around the edges of the frame can help prevent moisture from seeping in, which is particularly important in areas prone to heavy rainfall.

Common Applications of Screen Aluminum Extrusion

Screen aluminum extrusions are used in a variety of applications, including:

- Screened Porches: Creating a comfortable outdoor space that is protected from insects and debris.

- Window Screens: Enhancing ventilation while keeping bugs out.

- Patio Enclosures: Providing a versatile space for relaxation and entertainment.

- Pool Enclosures: Offering protection from insects while enjoying the pool area.

- Commercial Applications: Used in restaurants and cafes to create outdoor dining areas that are insect-free.

Conclusion

Installing screen aluminum extrusion is a rewarding project that can enhance the functionality and aesthetics of your outdoor spaces. By following the steps outlined in this article and utilizing the provided tips, you can achieve a durable and attractive installation. Remember to choose quality materials, maintain your screens regularly, and enjoy the benefits of your new screen enclosure. With the right approach, your screen aluminum extrusion will provide years of reliable service, allowing you to enjoy your outdoor areas without the nuisance of insects or debris.

Frequently Asked Questions

1. What type of screen mesh is best for aluminum extrusions?

Fiberglass mesh is commonly used due to its durability and resistance to tearing. Aluminum mesh is also an option for added strength, especially in high-traffic areas.

2. Can I paint aluminum extrusions?

Yes, aluminum extrusions can be painted. It is recommended to use a primer designed for metal surfaces to ensure proper adhesion. Additionally, consider using exterior-grade paint for better durability against the elements.

3. How do I maintain my screen aluminum extrusion?

Regularly clean the frames and screens with soap and water. Check for any signs of wear or damage and address them promptly. If the screen mesh becomes loose, re-tighten it to maintain its effectiveness.

4. Is it possible to install screen aluminum extrusion on uneven surfaces?

Yes, you can use shims to level the frame on uneven surfaces, ensuring a proper fit. This is particularly important for maintaining the structural integrity of the installation.

5. What tools do I need for installation?

Basic tools include a measuring tape, saw, drill, screwdriver, and safety gear. Additional tools may be required depending on your specific project, such as clamps for holding pieces in place during assembly.