Content Menu

● Understanding Telescoping Aluminum Extrusions

● Factors to Consider When Choosing Telescoping Aluminum Extrusions

>> Material Quality

>> Profile Design

>> Length and Size

>> Load Capacity

>> Surface Finish

● Applications of Telescoping Aluminum Extrusions

● How to Install Telescoping Aluminum Extrusions

● Maintenance Tips for Telescoping Aluminum Extrusions

● Frequently Asked Questions

>> 1.What Are the Benefits of Using Telescoping Aluminum Extrusions?

>> 2.How Do I Determine the Right Size for My Project?

>> 3.Can Telescoping Aluminum Extrusions Be Customized?

>> 4.What Industries Use Telescoping Aluminum Extrusions?

>> 5.How Do I Maintain Telescoping Aluminum Extrusions?

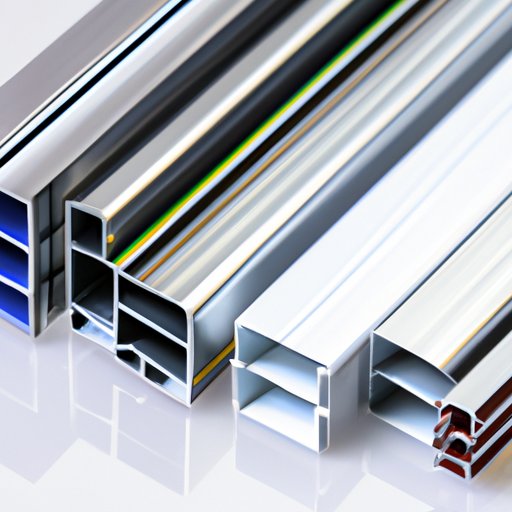

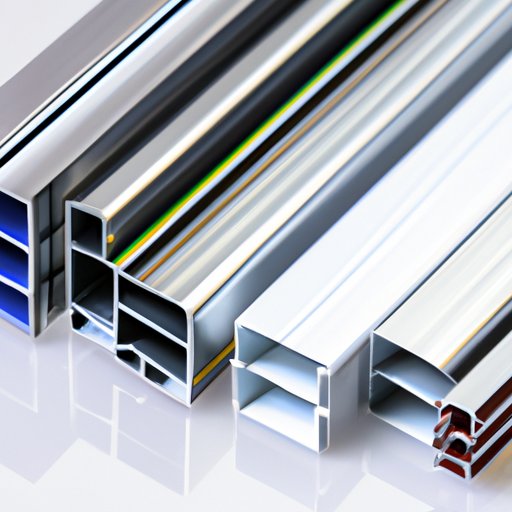

Understanding Telescoping Aluminum Extrusions

Telescoping aluminum extrusions consist of two or more sections that can slide within each other, allowing for adjustable lengths. This feature makes them ideal for applications where flexibility and adaptability are required. Common uses include adjustable tables, scaffolding, and various types of machinery. The lightweight nature of aluminum, combined with its strength and resistance to corrosion, makes it a popular choice for many industries.

Factors to Consider When Choosing Telescoping Aluminum Extrusions

Material Quality

The quality of the aluminum used in the extrusion process is crucial. Look for extrusions made from high-grade aluminum alloys, such as 6061 or 6063. These alloys offer excellent strength-to-weight ratios and are resistant to corrosion, making them suitable for both indoor and outdoor applications.

Profile Design

The design of the extrusion profile plays a significant role in its functionality. Different profiles offer varying levels of strength and flexibility. For instance, a square profile may provide more rigidity, while a round profile may allow for smoother movement. Consider the specific requirements of your project when selecting the profile design.

Length and Size

Telescoping aluminum extrusions come in various lengths and sizes. It's essential to choose an extrusion that fits your project's dimensions. Measure the required length and ensure that the selected extrusion can accommodate the necessary adjustments. Additionally, consider the diameter or width of the extrusion, as this will impact its overall strength and stability.

Load Capacity

Understanding the load capacity of the telescoping aluminum extrusion is vital, especially for applications that require support for heavy items. Each extrusion will have a specified load capacity based on its design and material. Be sure to consult the manufacturer's specifications to ensure that the extrusion can handle the intended load.

Surface Finish

The surface finish of the aluminum extrusion can affect its appearance and durability. Common finishes include anodizing, powder coating, and mill finish. Anodizing provides a protective layer that enhances corrosion resistance, while powder coating offers a wide range of color options. Choose a finish that aligns with your project's aesthetic and functional requirements.

Applications of Telescoping Aluminum Extrusions

Telescoping aluminum extrusions are used in various industries and applications. Here are some common uses:

1. Adjustable Furniture: Many modern furniture designs incorporate telescoping aluminum extrusions to allow for height adjustments. This feature is particularly popular in office desks and tables, enabling users to customize their workspace.

2. Scaffolding Systems: In construction, telescoping aluminum extrusions are often used in scaffolding systems. Their lightweight nature makes them easy to transport and assemble, while their strength ensures safety during construction projects.

3. Machinery and Equipment: Many industrial machines utilize telescoping aluminum extrusions for adjustable components. This allows for easy modifications and maintenance, enhancing the overall efficiency of the equipment.

4. Sports Equipment: Telescoping aluminum extrusions are commonly found in sports equipment, such as adjustable poles for tents or flags. Their ability to extend and retract makes them ideal for portable setups.

5. Automotive Applications: In the automotive industry, telescoping aluminum extrusions are used in various components, including adjustable seats and storage solutions. Their lightweight properties contribute to overall vehicle efficiency.

How to Install Telescoping Aluminum Extrusions

Installing telescoping aluminum extrusions is a straightforward process, but it requires careful planning and execution. Here are the steps to follow:

1. Gather Tools and Materials: Before starting the installation, gather all necessary tools, including a measuring tape, drill, screws, and brackets. Ensure you have the correct telescoping aluminum extrusions for your project.

2. Measure and Mark: Measure the desired height or length for the installation. Use a pencil to mark the locations where the extrusions will be attached. Double-check your measurements to ensure accuracy.

3. Prepare the Surface: If installing on a wall or other surface, ensure it is clean and free of debris. If necessary, use a level to ensure that the surface is even.

4. Attach Brackets: If your project requires brackets for support, attach them to the marked locations using screws and a drill. Ensure they are securely fastened to support the weight of the telescoping extrusions.

5. Insert the Extrusions: Slide the telescoping aluminum extrusions into place, ensuring they fit snugly within the brackets. Adjust the length as needed to achieve the desired height or configuration.

6. Secure the Extrusions: Once the extrusions are in place, secure them using screws or locking mechanisms provided by the manufacturer. This step is crucial for ensuring stability and safety.

7. Test the Installation: After installation, test the telescoping mechanism to ensure it operates smoothly. Make any necessary adjustments to improve functionality.

Maintenance Tips for Telescoping Aluminum Extrusions

To ensure the longevity and performance of your telescoping aluminum extrusions, regular maintenance is essential. Here are some tips to keep in mind:

1. Clean Regularly: Dust and debris can accumulate on the surface of the extrusions, affecting their appearance and functionality. Use a soft cloth and mild detergent to clean the extrusions regularly.

2. Inspect for Damage: Periodically inspect the extrusions for any signs of wear or damage. Look for dents, scratches, or corrosion that may compromise their integrity.

3. Lubricate Moving Parts: If your telescoping aluminum extrusions have moving parts, consider applying a lubricant to ensure smooth operation. This step can help prevent friction and wear over time.

4. Store Properly: If the extrusions are not in use, store them in a dry, cool place to prevent exposure to moisture and extreme temperatures. Proper storage can help maintain their condition.

5. Follow Manufacturer Guidelines: Always refer to the manufacturer's maintenance guidelines for specific recommendations related to your telescoping aluminum extrusions.

Frequently Asked Questions

1.What Are the Benefits of Using Telescoping Aluminum Extrusions?

Telescoping aluminum extrusions offer several benefits, including lightweight construction, corrosion resistance, and versatility. They can be easily adjusted to meet specific project requirements, making them ideal for various applications.

2.How Do I Determine the Right Size for My Project?

To determine the right size for your project, measure the required length and consider the load capacity needed. Consult the manufacturer's specifications to ensure the selected extrusion meets your project's demands.

3.Can Telescoping Aluminum Extrusions Be Customized?

Yes, many manufacturers offer customization options for telescoping aluminum extrusions. You can choose specific lengths, profiles, and finishes to suit your project's unique requirements.

4.What Industries Use Telescoping Aluminum Extrusions?

Telescoping aluminum extrusions are used in various industries, including construction, furniture design, automotive, and sports equipment. Their adaptability makes them suitable for a wide range of applications.

5.How Do I Maintain Telescoping Aluminum Extrusions?

Regular maintenance includes cleaning, inspecting for damage, lubricating moving parts, and following the manufacturer's guidelines. Proper care can extend the lifespan and performance of your extrusions.