Content Menu

● Understanding Aluminum Extrusion

>> What is Aluminum Extrusion?

>> Why Choose Aluminum Extrusion for DIY Projects?

>> Common Applications of Aluminum Extrusion Kits

● Key Components of an Aluminum Extruder Kit

● Factors to Consider When Choosing an Aluminum Extruder Kit

>> 1. Project Requirements

>> 2. Extrusion Profile

>> 3. Material and Finish

>> 4. Connector Types

>> 5. Kit Contents and Quality

>> 6. Supplier Reputation and Support

● Step-by-Step Guide to Selecting the Right Kit

● Tips for Working with Aluminum Extrusion Kits

● Conclusion

● FAQ

>> 1. What tools are needed to assemble an aluminum extrusion kit?

>> 2. Can aluminum extrusions be cut at home?

>> 3. What are the advantages of using T-slot aluminum over wood?

>> 4. Where can I order an "aluminum extruder kit"?

>> 5. Can AluFab help me design my build by suggesting which extrusion and fasteners to use?

● Citations:

Aluminum extrusion kits have become increasingly popular for DIY enthusiasts and professionals alike. These kits offer a versatile and modular solution for building a wide range of structures, from simple frames to complex machines. The "Industrial Erector Set"[2], as it's sometimes called, allows for easy assembly and modification, making it an ideal choice for various projects[6]. This article will guide you through the process of selecting the best aluminum extruder kit for your DIY applications, covering everything from understanding the basics of aluminum extrusion to the factors you should consider before making a purchase.

Understanding Aluminum Extrusion

What is Aluminum Extrusion?

Aluminum extrusion is a process where aluminum alloy is forced through a die of a specific shape, creating a long piece with the desired profile[5]. This process allows for the creation of complex shapes with consistent dimensions, making it a versatile material for various applications[5]. The resulting extrusions are strong, lightweight, and corrosion-resistant, making them suitable for both indoor and outdoor projects[5].

Why Choose Aluminum Extrusion for DIY Projects?

1. Modularity and Flexibility: Aluminum extrusion systems are highly modular, allowing for easy assembly and reconfiguration[6]. The T-slot design enables components to be connected at any point, making it simple to adjust and expand your projects as needed[6].

2. Strength and Durability: Aluminum is a strong and durable material, capable of withstanding significant loads and environmental factors[10]. This makes it ideal for building structures that need to be robust and long-lasting[10].

3. Lightweight: Despite its strength, aluminum is relatively lightweight, making it easy to handle and transport[10]. This is particularly beneficial for larger projects or those that require mobility[10].

4. Ease of Assembly: Aluminum extrusion kits are designed for easy assembly, often requiring only basic hand tools[6]. The T-slot system allows for bolting components together, eliminating the need for welding or other permanent joining methods[6].

5. Customization: Aluminum extrusions can be easily customized with various accessories and components, such as brackets, connectors, and panels[6]. This allows you to create highly specialized structures tailored to your specific needs[6].

Common Applications of Aluminum Extrusion Kits

- Sim Racing Rigs: Many sim racers use aluminum extrusion to build sturdy and adjustable racing rigs[2].

- Workstations: Aluminum extrusion can be used to create custom workstations that can be easily modified to fit your needs[6].

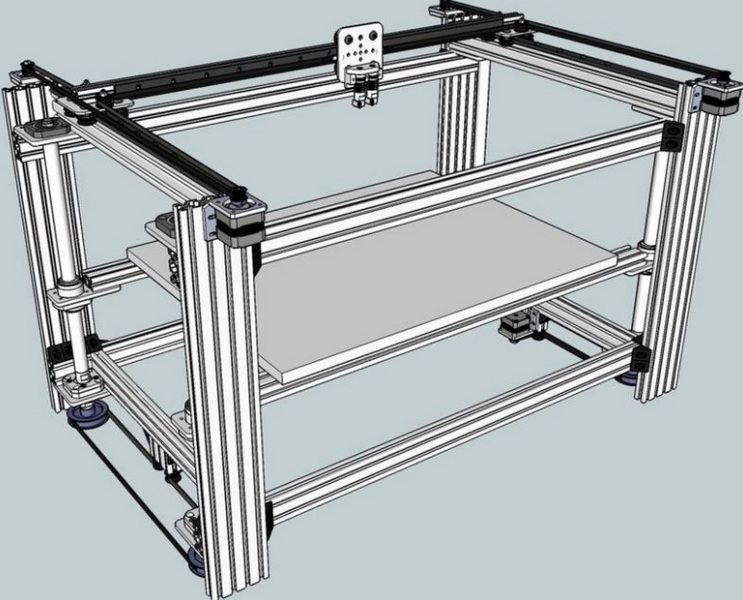

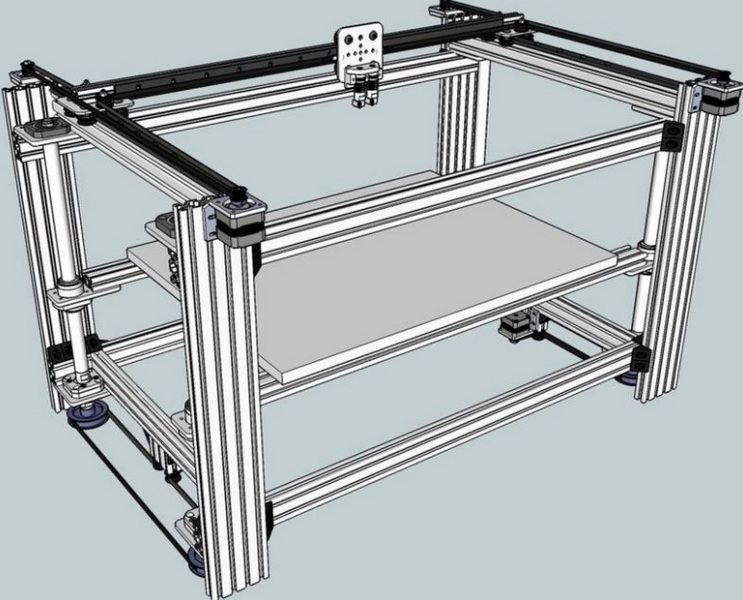

- Machine Frames: The strength and modularity of aluminum extrusion make it ideal for building machine frames[6].

- Greenhouses: Aluminum extrusion provides a durable and corrosion-resistant framework for greenhouses[5].

- Tank Stands and Canopies: T-Slot aluminum extrusion is an ideal material for building modern, strong tank stands and canopies[10].

Key Components of an Aluminum Extruder Kit

An aluminum extruder kit typically includes several essential components that work together to create a functional structure. Understanding these components is crucial for selecting the right kit for your project.

1. Aluminum Extrusions: These are the main structural elements of the kit. They come in various shapes and sizes, with T-slots along their surfaces for attaching other components[6].

2. Connectors: These are used to join extrusions together at various angles. Common types include corner brackets, joining plates, and pivot connectors[2].

3. Fasteners: These include screws, bolts, and T-nuts, which are used to secure the connectors and other components to the extrusions[2].

4. End Caps: These are used to cover the open ends of the extrusions, providing a finished look and preventing debris from entering[6].

5. Accessories: These can include items such as handles, casters, panels, and mounting plates, which add functionality and customization to your structure[6].

Factors to Consider When Choosing an Aluminum Extruder Kit

1. Project Requirements

The first step in choosing an aluminum extruder kit is to clearly define your project requirements. Consider the following factors:

- Size and Dimensions: Determine the overall size and dimensions of the structure you need to build. This will help you choose the appropriate length and size of the extrusions[6].

- Load Capacity: Estimate the maximum load that the structure will need to support. This will influence the choice of extrusion profile and connector types[10].

- Environmental Conditions: Consider the environmental conditions in which the structure will be used. If it will be exposed to moisture or corrosive substances, choose aluminum alloys with good corrosion resistance[5].

- Functionality: Identify any specific functions or features that the structure needs to have. This will help you select the appropriate accessories and components[6].

2. Extrusion Profile

The extrusion profile refers to the shape and dimensions of the aluminum extrusion. Different profiles offer different strength and stiffness characteristics. Common profiles include square, rectangular, and triangular[6].

- Series: Aluminum extrusions are often categorized by series, such as 10 series, 15 series, and 40 series. The series number typically corresponds to the T-slot width in millimeters or inches. Higher series numbers indicate larger and stronger extrusions[2].

- T-Slot Size: The T-slot size determines the size of the T-nuts and other fasteners that can be used with the extrusion. Ensure that the T-slot size is compatible with the components you plan to use[6].

- Wall Thickness: The wall thickness of the extrusion affects its strength and stiffness. Thicker walls provide greater load-bearing capacity but also add weight and cost[10].

3. Material and Finish

- Aluminum Alloy: The most common aluminum alloys used for extrusion are 6061 and 6063. 6061 is stronger and more corrosion-resistant, while 6063 is more easily extruded and offers a better surface finish[5].

- Surface Finish: Aluminum extrusions can be finished with various coatings to improve their appearance and corrosion resistance. Common finishes include anodizing, powder coating, and painting[5]. Anodizing provides a hard, durable, and corrosion-resistant finish, while powder coating offers a wide range of colors and textures[5].

4. Connector Types

Connectors are used to join extrusions together and create the desired structure. Different types of connectors offer different strength and flexibility characteristics[2].

- Corner Brackets: These are used to join extrusions at right angles. They are available in various sizes and shapes, with different numbers of mounting holes[2].

- Joining Plates: These are used to join extrusions in a straight line or at other angles. They provide a strong and rigid connection[2].

- Pivot Connectors: These allow extrusions to be joined at adjustable angles, providing flexibility in your design[6].

- Hidden Connectors: These provide a clean and seamless look by concealing the connection hardware inside the extrusion[2].

5. Kit Contents and Quality

- Completeness: Check the kit contents to ensure that it includes all the necessary components for your project. This includes extrusions, connectors, fasteners, end caps, and any other accessories you may need[4].

- Component Quality: Assess the quality of the components, paying attention to the materials, dimensions, and finish. High-quality components will ensure a strong and durable structure[4].

- Drawings and Bill of Materials: Comprehensive drawings and a bill of materials can significantly streamline the assembly process[1].

- Packaging: Individual packaging with labeled components can help with organization and prevent loss of parts[1].

6. Supplier Reputation and Support

- Reputation: Research the supplier's reputation by reading reviews and checking their ratings. A reputable supplier will offer high-quality products and excellent customer service[4].

- Support: Check if the supplier offers technical support and assistance with design and assembly. This can be invaluable if you encounter any problems during your project[4].

Step-by-Step Guide to Selecting the Right Kit

1. Define Your Project: Clearly outline the purpose, size, and load requirements of your project[6].

2. Choose the Right Extrusion Profile: Select an extrusion series and profile that matches your strength and size requirements[2].

3. Select Appropriate Connectors: Choose connectors that provide the necessary strength and flexibility for your design[2].

4. Consider Material and Finish: Decide on the appropriate aluminum alloy and surface finish based on your environmental conditions and aesthetic preferences[5].

5. Evaluate Kit Contents: Ensure that the kit includes all the necessary components and that they are of high quality[4].

6. Check Supplier Reputation: Research the supplier's reputation and ensure they offer adequate support[4].

7. Compare Prices: Compare prices from different suppliers to find the best value for your money[4].

Tips for Working with Aluminum Extrusion Kits

- Plan Ahead: Before you start building, create a detailed plan and design. This will help you avoid mistakes and ensure that you have all the necessary components[6].

- Use the Right Tools: Use the appropriate tools for cutting and assembling the extrusions. This includes a miter saw with an aluminum-cutting blade, Allen wrenches, and a torque wrench[1].

- Follow Instructions: Carefully follow the assembly instructions provided with the kit. This will ensure that you assemble the structure correctly and safely[1].

- Tighten Fasteners: Ensure that all fasteners are properly tightened to provide a strong and rigid connection[6].

- Be Precise: Pay attention to detail and ensure that all cuts and connections are accurate. This will improve the overall quality and appearance of your structure[6].

Conclusion

Choosing the best "aluminum extruder kit" for your DIY applications requires careful consideration of your project requirements, the extrusion profile, material, connector types, kit contents, and supplier reputation. By following the guidelines outlined in this article, you can select a kit that meets your needs and allows you to build a strong, durable, and customized structure[4]. Whether you're building a sim racing rig, a workstation, or a machine frame, an aluminum extrusion kit can provide a versatile and cost-effective solution[6].

FAQ

1. What tools are needed to assemble an aluminum extrusion kit?

Basic hand tools such as a tape measure and Allen wrenches are typically needed[1]. T-handles are useful for applying torque efficiently, and wrenches may be needed depending on the connectors[1]. A rubber mallet can also be helpful[1].

2. Can aluminum extrusions be cut at home?

Yes, aluminum extrusions can be cut at home using a miter saw with a blade designed for cutting aluminum[7]. It is recommended to use a 60-72 tooth carbide-tipped triple chip blade[10]. Always use proper eye and safety protection when cutting T-Slot, as cutting has a tendency to produce tiny/sharp/hot aluminum shavings[10]!

3. What are the advantages of using T-slot aluminum over wood?

Building with T-Slot has a number of advantages over building with wood. Aluminum extrusion is stronger and lighter than wood[10]. Once the cuts are made, it can also be put together and taken down easily[6][10].

4. Where can I order an "aluminum extruder kit"?

You can easily order "aluminum extruder kits" and connector pieces online at various suppliers[6]. Many suppliers also offer custom cutting, end machining, and kitted materials to meet your project's specific needs[4][6].

5. Can AluFab help me design my build by suggesting which extrusion and fasteners to use?

Yes, AluFab is happy to help suggest and educate their customers on the best and easiest way to build and assemble your project. They can suggest fasteners and hardware and make sure that any hardware you order is compatible with the corresponding extrusion that you are ordering[4].

Citations:

[1] https://www.youtube.com/watch?v=msIBFiahdzk

[2] https://www.reddit.com/r/simracing/comments/gadira/diy_8020_sim_racing_rig_buyerbuild_guide/

[3] https://www.reddit.com/r/Rad_Decentralization/comments/hqycli/aluminum_extrusion_making_machine_has_anyone_seen/

[4] https://www.alufabinc.com/faqs/

[5] https://tricityextrusion.com/roxyfileman/uploads/AEC_2018_Aluminum_Extrusion_Manual.pdf

[6] https://blog.airlinehyd.com/how-to-build-anything-with-aluminum-extrusion-in-3-steps

[7] https://hackaday.com/2021/05/25/getting-started-with-aluminum-extrusions/

[8] https://www.pinterest.com/edhyslip/aluminum-extrusion-projects/

[9] https://www.youtube.com/watch?v=gJIChIs4g6A

[10] https://www.reef2reef.com/threads/guide-to-diy-with-t-slot-aluminum.903885/