Content Menu

● Introduction

● Understanding T-Slot and V-Slot Aluminum Profiles

>> Key Differences Between T-Slot and V-Slot Profiles

● Key Benefits of T-Slot Aluminum Profiles

>> A. Versatility in Applications

>> B. Enhanced Structural Integrity

>> C. Easy Assembly and Modification

● Key Benefits of V-Slot Aluminum Profiles

>> A. Smooth Linear Motion

>> B. Lightweight and Strong

>> C. Modular Design for Customization

● Practical Applications of T-Slot and V-Slot Aluminum Profiles

>> T-Slot Applications

>> V-Slot Applications

● Accessories and Components for T-Slot and V-Slot Systems

● Conclusion

● Frequently Asked Questions

>> 1. What are the main differences between T-slot and V-slot aluminum profiles?

>> 2. In what applications are T-slot profiles typically used?

>> 3. What advantages do V-slot profiles offer for CNC machines?

>> 4. Can T-slot and V-slot profiles be used together in a project?

>> 5. What accessories are available for T-slot and V-slot systems?

Introduction

Aluminum extrusion has revolutionized the manufacturing and construction industries, providing versatile and lightweight solutions for a variety of applications. Among the most popular types of aluminum profiles are T-slot and V-slot extrusions. Both designs offer unique advantages, making them suitable for different structural applications. This article will explore the key differences between T-slot and V-slot aluminum profiles, focusing on their structural applications, benefits, and ideal use cases.

Understanding T-Slot and V-Slot Aluminum Profiles

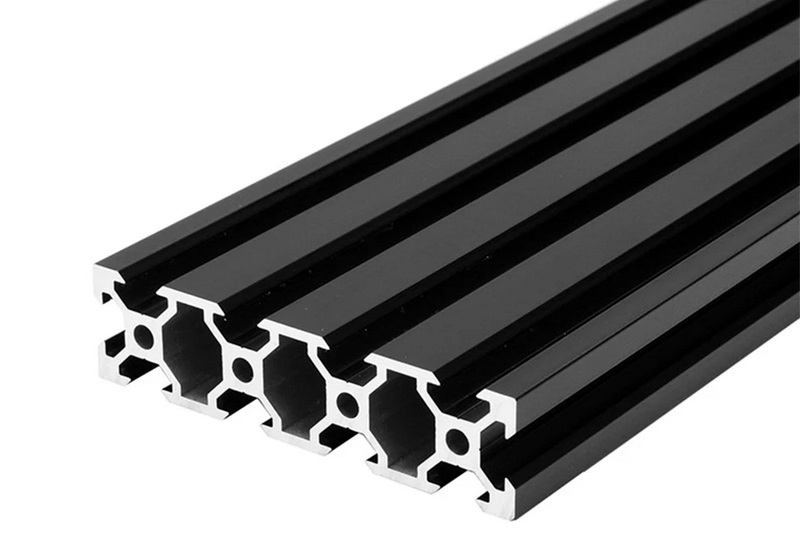

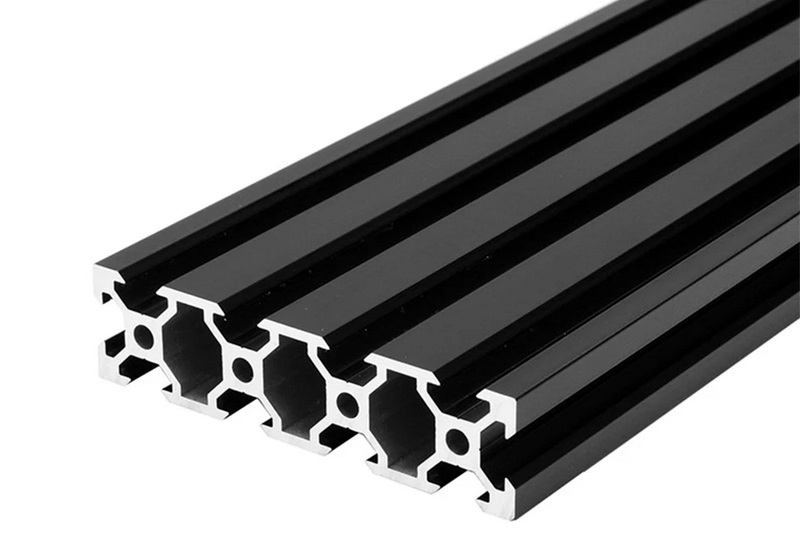

T-slot aluminum profiles feature a T-shaped groove that runs along the length of the profile. This design allows for easy attachment of components, making it a popular choice for modular construction. T-slot profiles are often used in building frames, workstations, and machine guards due to their strength and adaptability.

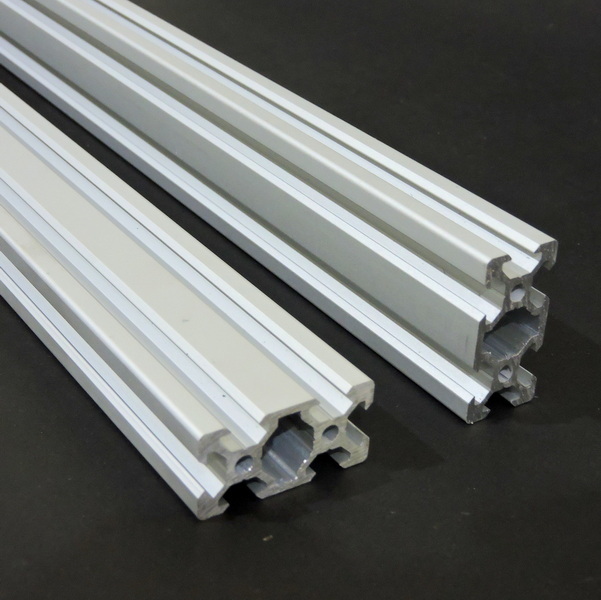

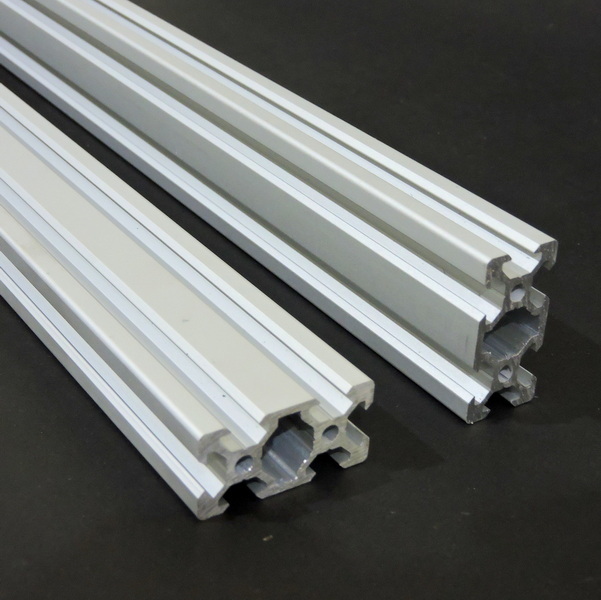

In contrast, V-slot aluminum profiles have a V-shaped groove that provides a different set of advantages. The V-slot design is particularly beneficial for linear motion applications, such as in CNC machines and 3D printers. The groove allows for smooth movement of wheels or bearings, making it ideal for systems that require precise linear motion.

Key Differences Between T-Slot and V-Slot Profiles

1. Design and Functionality: The primary difference between T-slot and V-slot profiles lies in their groove design. T-slot profiles are designed for versatility in connecting various components, while V-slot profiles are optimized for linear motion.

2. Applications: T-slot profiles are commonly used in structural applications where strength and stability are paramount. V-slot profiles, on the other hand, excel in applications requiring smooth movement and precision, such as robotics and automation.

3. Assembly and Modularity: T-slot profiles allow for easy assembly and disassembly, making them ideal for temporary structures or setups that require frequent modifications. V-slot profiles also offer modularity but are more specialized for specific applications.

Key Benefits of T-Slot Aluminum Profiles

A. Versatility in Applications

T-slot aluminum profiles are incredibly versatile, making them suitable for a wide range of applications. They can be used to create everything from simple frames to complex machinery. The ability to easily attach components at any point along the profile allows for customization and adaptability in design.

B. Enhanced Structural Integrity

One of the standout features of T-slot profiles is their structural integrity. The T-shaped groove provides additional strength, allowing for the construction of robust frameworks that can support heavy loads. This makes T-slot profiles an excellent choice for industrial applications where durability is essential.

C. Easy Assembly and Modification

T-slot profiles are designed for quick assembly and modification. The use of standard fasteners and connectors means that components can be easily added or removed without the need for specialized tools. This flexibility is particularly beneficial in environments where designs need to be adjusted frequently.

Key Benefits of V-Slot Aluminum Profiles

A. Smooth Linear Motion

V-slot aluminum profiles are specifically designed to facilitate smooth linear motion. The V-shaped groove allows for the use of wheels or bearings that glide effortlessly along the track. This feature is crucial in applications such as CNC machines and 3D printers, where precision and accuracy are paramount.

B. Lightweight and Strong

Despite their lightweight nature, V-slot profiles maintain a high strength-to-weight ratio. This makes them ideal for applications where weight is a concern, such as in robotics or portable equipment. The aluminum material also provides resistance to corrosion, ensuring longevity in various environments.

C. Modular Design for Customization

Like T-slot profiles, V-slot profiles offer a modular design that allows for easy customization. Users can create unique setups tailored to their specific needs, whether for a DIY project or a professional application. The ability to mix and match components enhances the versatility of V-slot systems.

Practical Applications of T-Slot and V-Slot Aluminum Profiles

T-Slot Applications

T-slot aluminum profiles are widely used in various industries, including manufacturing, construction, and automation. Some common applications include:

- Workstations: T-slot profiles can be used to create ergonomic workstations that can be easily adjusted to suit different tasks.

- Machine Guards: The strength of T-slot profiles makes them ideal for constructing safety guards around machinery.

- Conveyor Systems: T-slot profiles can be used to build conveyor systems that transport materials efficiently.

V-Slot Applications

V-slot aluminum profiles are particularly popular in applications that require linear motion. Some notable uses include:

- CNC Machines: V-slot profiles provide the necessary support and smooth movement for CNC machines, ensuring precise cutting and shaping of materials.

- 3D Printers: The V-slot design allows for the smooth operation of print heads, contributing to the accuracy of 3D printing.

- Robotics: V-slot profiles are often used in robotic arms and other automated systems where linear motion is essential.

Accessories and Components for T-Slot and V-Slot Systems

Both T-slot and V-slot profiles can be enhanced with a variety of accessories and components. For T-slot systems, connectors, brackets, and fasteners are essential for building stable structures. These components allow users to create custom configurations that meet their specific needs.

For V-slot systems, wheels, bearings, and linear guides are crucial for ensuring smooth movement. These accessories are designed to fit perfectly within the V-shaped groove, providing stability and precision in motion. Users can also find various end caps and connectors to complete their V-slot setups.

Conclusion

In summary, both T-slot and V-slot aluminum profiles offer unique advantages for structural applications. T-slot profiles excel in versatility and strength, making them suitable for a wide range of industrial applications. V-slot profiles, on the other hand, are optimized for linear motion, making them ideal for CNC machines, 3D printers, and robotics.

When choosing between T-slot and V-slot profiles, it is essential to consider the specific requirements of your project. Understanding the differences in design, functionality, and application will help you make an informed decision that best suits your needs.

Frequently Asked Questions

1. What are the main differences between T-slot and V-slot aluminum profiles?

T-slot profiles feature a T-shaped groove for versatile connections, while V-slot profiles have a V-shaped groove designed for smooth linear motion.

2. In what applications are T-slot profiles typically used?

T-slot profiles are commonly used in workstations, machine guards, and conveyor systems due to their strength and adaptability.

3. What advantages do V-slot profiles offer for CNC machines?

V-slot profiles provide smooth linear motion, which is crucial for the precise operation of CNC machines, ensuring accurate cutting and shaping.

4. Can T-slot and V-slot profiles be used together in a project?

Yes, T-slot and V-slot profiles can be used together in a project, allowing for a combination of structural strength and linear motion capabilities.

5. What accessories are available for T-slot and V-slot systems?

T-slot systems typically use connectors, brackets, and fasteners, while V-slot systems utilize wheels, bearings, and linear guides to enhance movement and stability.