Content Menu

● Introduction

● Understanding Aluminum Extrusion Profiles

● Advantages of Aluminum Extrusion Profiles

>> Lightweight and Durable

>> Customizability

>> Cost-Effectiveness

● Applications of Aluminum Extrusion Profiles in Sliding Mechanisms

>> Industrial Automation

>> Furniture and Fixtures

>> Transportation

● Conclusion

● Related Questions

>> 1. What are the key benefits of using aluminum extrusion sliders in linear motion systems?

>> 2. How do modular aluminum slides improve industrial automation?

>> 3. Can aluminum extrusion profiles be customized for specific applications?

>> 4. What industries benefit the most from aluminum extrusion sliders?

>> 5. How do aluminum sliders contribute to cost savings in manufacturing?

Introduction

In the realm of modern engineering and manufacturing, the importance of efficient linear motion systems cannot be overstated. These systems are integral to a wide array of applications, from industrial automation to robotics and even furniture design. At the heart of many of these systems lies the aluminum extrusion slider, a component that offers a unique combination of strength, versatility, and lightweight properties. This article delves into how modular aluminum slides enhance linear motion systems, exploring their benefits, applications, and the technology behind them.

Understanding Aluminum Extrusion Profiles

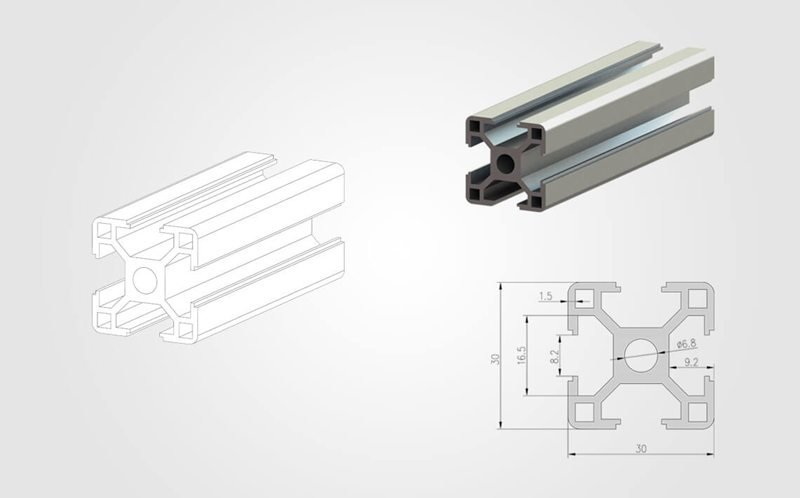

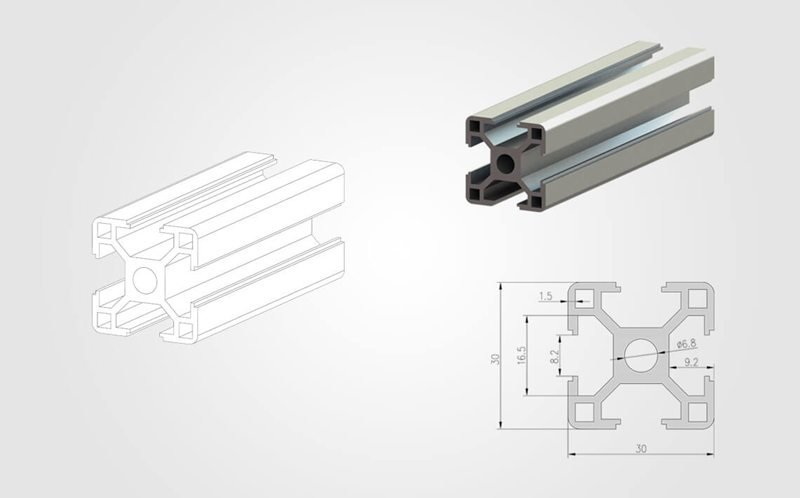

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. This process allows for the creation of complex shapes that can be tailored to specific applications. The resulting aluminum extrusion profiles are lightweight yet strong, making them ideal for various uses, including linear motion systems.

Modular aluminum slides are a specific type of aluminum extrusion designed for linear motion applications. They typically feature a T-slot design, which allows for easy assembly and customization. This modularity is a significant advantage, as it enables engineers and designers to create systems that meet their precise needs without the constraints of traditional manufacturing methods.

Advantages of Aluminum Extrusion Profiles

Lightweight and Durable

One of the most significant advantages of aluminum extrusion sliders is their lightweight nature. Aluminum is inherently lighter than many other metals, such as steel, which makes it easier to handle and install. This lightweight characteristic is particularly beneficial in applications where weight is a critical factor, such as in aerospace and automotive industries.

Despite their lightness, aluminum extrusion sliders are incredibly durable. They can withstand significant loads and stresses, making them suitable for heavy-duty applications. The strength-to-weight ratio of aluminum is one of the highest among metals, ensuring that these sliders can perform reliably over time.

Customizability

The modular nature of aluminum extrusion profiles allows for a high degree of customizability. Engineers can design and manufacture sliders that fit specific dimensions and requirements, ensuring optimal performance in their intended applications. This flexibility is particularly valuable in industries where unique configurations are necessary.

For instance, in a robotic assembly line, the ability to customize the length and width of aluminum slides can lead to more efficient operations. By tailoring the components to fit the exact needs of the system, manufacturers can enhance productivity and reduce downtime.

Cost-Effectiveness

While the initial investment in aluminum extrusion sliders may be higher than some alternatives, the long-term cost-effectiveness is undeniable. The durability of aluminum means that these components require less frequent replacement, leading to lower maintenance costs over time. Additionally, the ease of installation and customization can reduce labor costs associated with system setup and modifications.

In many cases, the use of aluminum extrusion profiles can lead to significant savings in both material and labor costs, making them an attractive option for manufacturers looking to optimize their operations.

Applications of Aluminum Extrusion Profiles in Sliding Mechanisms

Industrial Automation

Aluminum extrusion sliders play a crucial role in industrial automation. They are commonly used in conveyor systems, robotic arms, and automated assembly lines. The smooth linear motion provided by these sliders ensures that products move efficiently through various stages of production.

For example, in a conveyor system, aluminum slides can facilitate the movement of goods from one station to another, reducing friction and wear on the components. This efficiency not only speeds up production but also minimizes the risk of damage to the products being transported.

Furniture and Fixtures

In the realm of furniture design, modular aluminum slides are increasingly being used to create innovative and functional pieces. Sliding doors, for instance, benefit from the smooth operation provided by aluminum extrusion sliders. The lightweight nature of aluminum allows for larger doors that are easy to open and close, enhancing user experience.

Moreover, modular aluminum slides can be integrated into modular furniture systems, allowing for customizable configurations. This adaptability is particularly appealing in modern living spaces where flexibility and functionality are paramount.

Transportation

The transportation industry also leverages the benefits of aluminum extrusion profiles. In automotive applications, aluminum sliders are used in various components, including sliding doors and hatches. The lightweight nature of aluminum contributes to overall vehicle efficiency, improving fuel economy and performance.

In aerospace, aluminum extrusion sliders are utilized in aircraft components, where weight reduction is critical. The strength and durability of aluminum ensure that these components can withstand the rigors of flight while maintaining safety and reliability.

Conclusion

Modular aluminum slides are a vital component in enhancing linear motion systems across various industries. Their lightweight and durable nature, combined with customizability and cost-effectiveness, make them an ideal choice for engineers and designers. From industrial automation to furniture design and transportation, the applications of aluminum extrusion sliders are vast and varied.

As technology continues to advance, the role of aluminum extrusion profiles in linear motion systems will likely expand, leading to even more innovative solutions. By understanding the benefits and applications of these components, manufacturers can optimize their operations and improve overall efficiency.

Related Questions

1. What are the key benefits of using aluminum extrusion sliders in linear motion systems?

Aluminum extrusion sliders offer lightweight durability, customizability, and cost-effectiveness, making them ideal for various applications.

2. How do modular aluminum slides improve industrial automation?

They provide smooth linear motion, reducing friction and wear, which enhances the efficiency of conveyor systems and robotic arms.

3. Can aluminum extrusion profiles be customized for specific applications?

Yes, the modular nature of aluminum extrusion allows for high levels of customization to meet specific design requirements.

4. What industries benefit the most from aluminum extrusion sliders?

Industries such as manufacturing, furniture design, transportation, and aerospace benefit significantly from the use of aluminum extrusion sliders.

5. How do aluminum sliders contribute to cost savings in manufacturing?

Their durability leads to lower maintenance and replacement costs, while their ease of installation reduces labor expenses.