Content Menu

● Introduction to Extrusion Equipment

>> Applications of Extrusion Machines

● Key Factors in Selecting Extrusion Equipment

● Types of Extrusion Machines

● Benefits of Using Extrusion Equipment PDFs

● Applications of Extrusion in Various Industries

● Choosing the Right Extrusion Machine

● Conclusion

● Frequently Asked Questions

>> 1. What are the key factors to consider when selecting an extrusion machine?

>> 2. How do single-screw and twin-screw extruders differ?

>> 3. What are the benefits of using extrusion equipment PDFs?

>> 4. What industries commonly use extrusion technology?

>> 5. How can I optimize the performance of my extrusion equipment?

● Citations:

Choosing the right extrusion equipment is crucial for the production of plastics, metals, and other materials. Utilizing an extrusion equipment PDF can help you better understand and select the most suitable equipment for your needs. Below is a comprehensive guide on how to leverage these PDFs to optimize your equipment selection process.

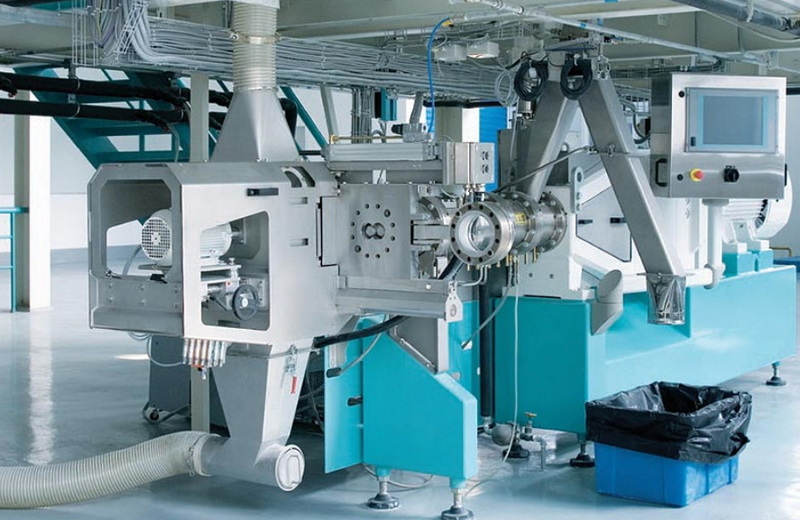

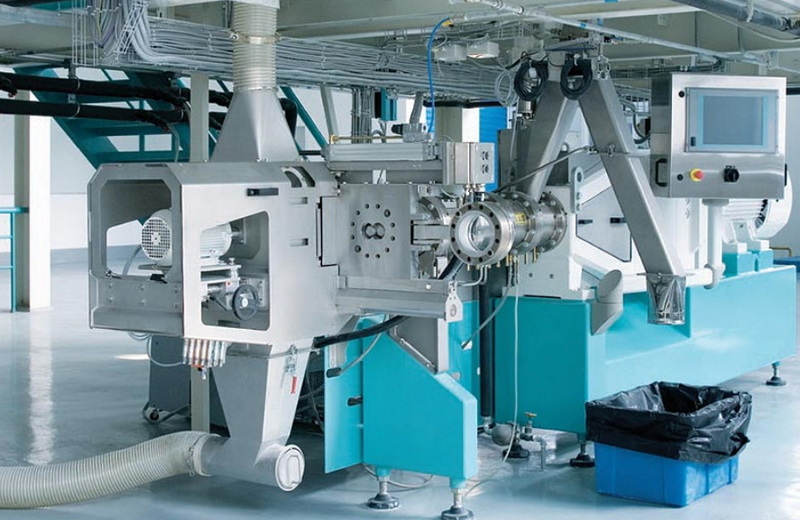

Introduction to Extrusion Equipment

Extrusion equipment is a vital tool in various industries, including plastics, metals, and food processing. It involves heating and shaping raw materials to produce products with specific shapes and sizes. The process allows for precise control over the final product's properties, making it essential for manufacturing a wide range of items, from plastic pipes and sheets to metal profiles and food products.

Applications of Extrusion Machines

Extrusion machines are widely used across different sectors:

- Plastics Industry: Extruders are extensively used to produce plastic products like pipes, sheets, films, and profiles. These products are essential in packaging, construction, and automotive industries[1][3].

- Food Industry: Food extruders modify the texture, shape, and nutritional content of food products, making them valuable for producing snacks, cereals, and pet foods[1].

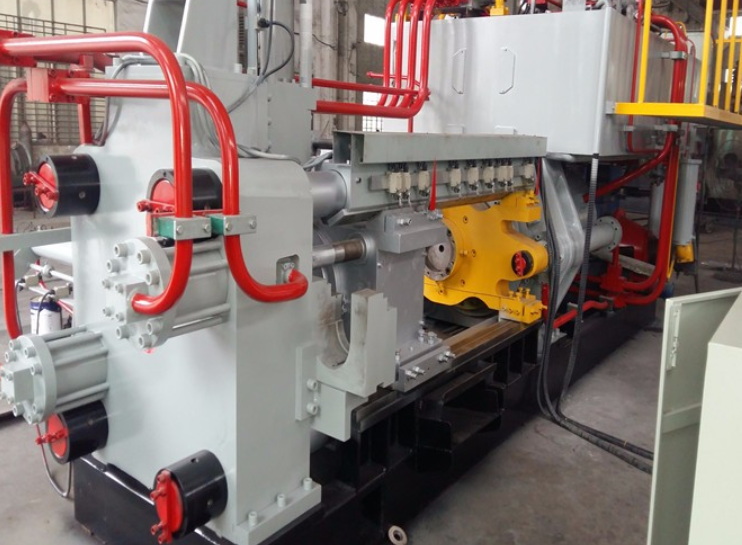

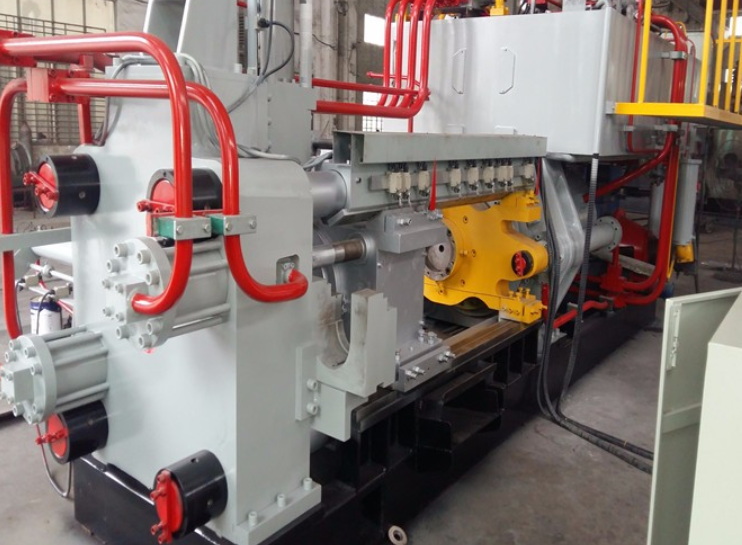

- Metals Industry: Metal extrusion is used to create complex shapes from metals like aluminum, copper, and steel, commonly applied in automotive, aerospace, and construction industries[1][7].

Key Factors in Selecting Extrusion Equipment

When selecting extrusion equipment, several factors must be considered:

1. Capacity and Output: Determine the desired production volume and speed to ensure the machine meets your production demands. Assess the extruder's maximum output capacity in terms of kilograms per hour[2].

2. Type of Extruder: Extruder machines come in various configurations, such as single-screw, twin-screw, co-rotating, or counter-rotating options. Each type offers unique advantages depending on the application[2][3].

3. Material Compatibility: Ensure the extruder is compatible with the material you plan to process. Different materials have varying melting points and flow characteristics[4].

4. Energy Efficiency: Opt for energy-efficient models to reduce operating costs and environmental impact. Features like advanced control systems and optimized motor drives can significantly improve efficiency[2].

5. Quality and Reliability: Choose reputable manufacturers known for their high-quality equipment and reliable performance. This ensures consistent production output and minimizes downtime[2].

Types of Extrusion Machines

Extrusion machines vary based on their application and design:

- Single-Screw Extruders: These are the most common type, suitable for processing thermoplastics like polyethylene and polypropylene. They are cost-effective and easy to operate[3].

- Twin-Screw Extruders: These offer better mixing capabilities and are used for complex formulations requiring high homogenization, such as filled plastics and masterbatches[3].

- Multilayer Plastic Sheet Extruders: Designed to produce products with multiple layers of different plastics, often used in packaging for barrier films[3].

Benefits of Using Extrusion Equipment PDFs

Using extrusion equipment PDFs provides several benefits:

- Detailed Technical Parameters: PDFs offer comprehensive technical specifications, helping you understand the equipment's performance and suitability for your needs.

- Operation Guides: They typically include operation manuals, ensuring correct usage and maintenance.

- Comparative Analysis: PDFs enable you to compare different equipment models, facilitating informed decisions.

Applications of Extrusion in Various Industries

Extrusion technology is applied in numerous industries:

- Solar and Automotive Industries: Extruded plastics are used in solar panel frames and automotive parts like weather seals and interior trim components[5].

- Appliance Industry: Extruded plastics provide insulation and sealing properties, enhancing appliance efficiency[5].

- Construction Industry: Used in windows, doors, and other architectural elements for weather resistance and thermal efficiency[5].

Choosing the Right Extrusion Machine

To select the right extrusion machine, consider the following:

1. Business Objectives: Align your choice with business goals, such as expanding operations or enhancing energy efficiency[6].

2. Return on Investment (ROI): Evaluate the profit potential compared to the initial investment[6].

3. Break-Even Point: Consider how long it takes for the equipment to pay for itself[6].

Conclusion

Choosing the right extrusion equipment is crucial for efficient production and product quality. By utilizing extrusion equipment PDFs, you can gain a deeper understanding of technical parameters, operation guides, and comparative analyses. This helps in making informed decisions tailored to your specific needs. Additionally, considering factors like material compatibility, production capacity, and energy efficiency ensures that you select the most suitable equipment for your operations.

Frequently Asked Questions

1. What are the key factors to consider when selecting an extrusion machine?

When selecting an extrusion machine, consider factors such as capacity and output, type of extruder, material compatibility, energy efficiency, and quality and reliability of the manufacturer[2][4].

2. How do single-screw and twin-screw extruders differ?

Single-screw extruders are suitable for simple applications and cost-effective, while twin-screw extruders offer better mixing capabilities and are used for complex formulations[3].

3. What are the benefits of using extrusion equipment PDFs?

Using extrusion equipment PDFs provides detailed technical parameters, operation guides, and comparative analyses, helping you make informed decisions[3].

4. What industries commonly use extrusion technology?

Extrusion technology is widely used in plastics, metals, food processing, automotive, aerospace, and construction industries[1][7].

5. How can I optimize the performance of my extrusion equipment?

Optimizing performance involves regular maintenance, ensuring proper operation conditions, and selecting the right materials for processing[4].

Citations:

[1] https://engitech.in/extrusion-machines-and-extruders-guide/

[2] https://www.linkedin.com/pulse/key-buying-pipe-extrusion-machinery-important-factors-nader-amin

[3] https://www.cnchaoxu.com/news-center/what-are-the-different-types-of-plastic-extrusion-machines

[4] https://jieyatwinscrew.com/blog/small-extrusion-machine/

[5] https://www.clarkrandp.com/6-common-applications-of-plastic-extrusion/

[6] https://www.bausano.com/en/press-and-news/are-there-objective-parameters-to-choose-the-right-machine

[7] https://www.globalspec.com/learnmore/manufacturing_process_equipment/manufacturing_equipment_components/extrusion_machines

[8] https://www.chenyu.com.tw/en/news_i_Selecting-WPC-Profile-Extrusion-Machines

[9] https://www.moldingmachinetepai.com/resources/plastic-extrusion-machines-introduction-types-application.html

[10] https://www.outashi.com/blog/factors-to-consider-when-selecting-aluminum-extrusion-machine-id32.html

[11] https://jieyatwinscrew.com/blog/exploring-the-world-of-extrusion-machines-understanding-the-basics-and-benefits/

[12] https://drts.com/extruder-machine-manufacturer/

[13] https://www.macocorporation.com/blog/extruder-machine/

[14] https://www.cowellextrusion.com/key-points-when-choosing-a-plastic-extruder-machine/

[15] https://www.thermofisher.com/hk/en/home/industrial/manufacturing-processing/extrusion-compounding-equipment/applications.html

[16] https://paulmurphyplastics.com/industry-news-blog/3-tips-you-should-consider-when-choosing-a-plastic-extrusion-machine/

[17] https://plasticextrusiontech.net/machines-used-in-the-plastic-extrusion-process/

[18] https://www.chuangboextrusion.com/7-factors-that-can-help-you-choose-a-suitable-twin-screw-extruder-id42094737.html