Content Menu

● Understanding F-Channel Aluminum Extrusions

● Tools and Materials Needed

>> Tools

>> Materials

● Step-by-Step Installation Process

>> Step 1: Measure and Mark

>> Step 2: Cut the F-Channel

>> Step 3: Prepare the Surface

>> Step 4: Position the F-Channel

>> Step 5: Secure the F-Channel

>> Step 6: Apply Sealant

>> Step 7: Install Panels or Trim

>> Step 8: Final Inspection

● Tips for Successful Installation

● Common Mistakes to Avoid

● Maintenance of F-Channel Aluminum Extrusions

● Conclusion

● Frequently Asked Questions

>> 1. What is the best way to cut F-channel aluminum extrusions?

>> 2. Can I install F-channel aluminum extrusions on uneven surfaces?

>> 3. How do I choose the right size F-channel for my project?

>> 4. Is sealant necessary for indoor installations?

>> 5. How often should I inspect my F-channel installations?

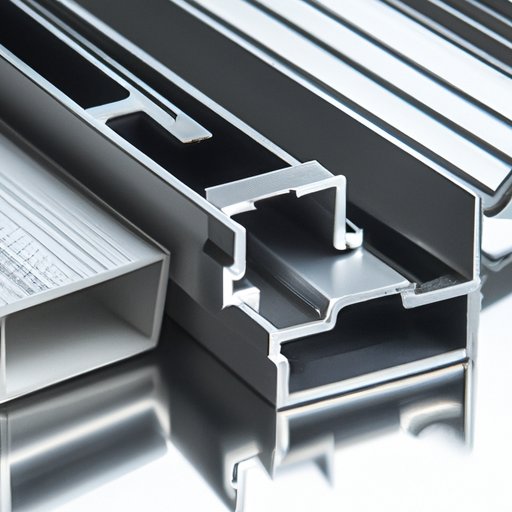

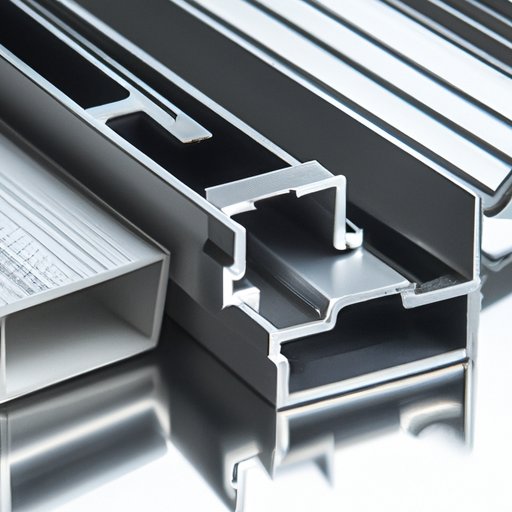

Understanding F-Channel Aluminum Extrusions

Installing F-channel aluminum extrusions can be a straightforward process if you follow the right steps and techniques. F-channel extrusions are commonly used in various applications, including siding, roofing, and other structural elements. The "F" shape allows for easy attachment and alignment, making them a popular choice among builders and DIY enthusiasts.

F-channel aluminum extrusions are designed to provide a strong and durable framework for various construction projects. They are typically used to support panels, trim, and other materials. The benefits of using F-channel aluminum extrusions include durability, lightweight properties, versatility, and aesthetic appeal. Aluminum is resistant to rust and corrosion, making it ideal for outdoor applications. Additionally, F-channels can be used in various applications, from siding to roofing and more, and are available in various finishes to enhance the overall look of your project.

Tools and Materials Needed

Before you begin the installation process, gather the necessary tools and materials:

Tools

- Meuring Tape: For accurate measurements.

- Level: To ensure your installation is straight and even.

- Drill: For making holes and securing the F-channel.

- Screwdriver: For fastening screws.

- Saw: A miter saw or hacksaw for cutting the aluminum extrusions.

- Safety Gear: Gloves and safety glasses to protect yourself during installation.

Materials

- F-Channel Aluminum Extrusions: Choose the appropriate length and thickness for your project.

- Screws: Use corrosion-resistant screws suitable for aluminum.

- Sealant: A high-quality sealant to prevent water infiltration.

- Backing Material: Depending on your application, you may need a backing material for added support.

Step-by-Step Installation Process

Step 1: Measure and Mark

Begin by measuring the area where you will install the F-channel. Use your measuring tape to determine the length needed for the extrusion. Mark the locations where the F-channel will be installed, ensuring that your marks are level and straight. Accurate measurements are crucial to avoid any misalignment during installation.

Step 2: Cut the F-Channel

Using a saw, cut the F-channel aluminum extrusions to the desired length. Make sure to wear safety glasses and gloves during this process to protect yourself from metal shavings. After cutting, smooth any sharp edges with a file to prevent injury during installation. Proper cutting techniques will ensure that the F-channel fits perfectly into the designated area.

Step 3: Prepare the Surface

Before attaching the F-channel, ensure that the surface is clean and free of debris. If you are installing the F-channel on a wall, check for any protrusions or obstacles that may interfere with the installation. A clean surface will help the F-channel adhere better and provide a more secure installation.

Step 4: Position the F-Channel

Align the F-channel with your marked locations. Use a level to ensure that it is straight. If you are installing multiple pieces, make sure they are aligned properly with each other. Proper alignment is essential for both functionality and aesthetics.

Step 5: Secure the F-Channel

Using your drill, make pilot holes through the F-channel into the surface below. This will help prevent the aluminum from cracking during installation. Once the pilot holes are made, secure the F-channel using corrosion-resistant screws. Be careful not to overtighten, as this can damage the aluminum. Proper fastening techniques will ensure that the F-channel remains securely in place.

Step 6: Apply Sealant

To prevent water infiltration, apply a high-quality sealant along the edges of the F-channel. This step is crucial, especially for outdoor applications, as it helps protect the underlying structure from moisture damage. Sealant not only provides waterproofing but also enhances the longevity of the installation.

Step 7: Install Panels or Trim

Once the F-channel is securely in place, you can proceed to install the panels or trim that will be supported by the F-channel. Follow the manufacturer's instructions for the specific materials you are using. Proper installation of panels or trim will ensure a cohesive look and functionality.

Step 8: Final Inspection

After installation, conduct a final inspection to ensure everything is secure and properly aligned. Check for any gaps or areas where sealant may need to be reapplied. A thorough inspection will help identify any potential issues before they become significant problems.

Tips for Successful Installation

- Work in Good Lighting: Ensure you have adequate lighting to see your measurements and markings clearly. Good visibility will help you avoid mistakes during installation.

- Double-Check Measurements: Always double-check your measurements before cutting to avoid mistakes. Accurate measurements are key to a successful installation.

- Use a Helper: If possible, have someone assist you during installation, especially when handling long pieces of F-channel. Having an extra set of hands can make the process smoother and more efficient.

- Follow Manufacturer Guidelines: Always refer to the manufacturer's guidelines for specific installation instructions related to the products you are using. Manufacturer recommendations can provide valuable insights and tips.

Common Mistakes to Avoid

1. Skipping the Pilot Holes: Failing to make pilot holes can lead to cracking or damaging the aluminum. Always make pilot holes to ensure a secure fit.

2. Not Using Sealant: Neglecting to apply sealant can result in water damage over time. Sealant is essential for protecting your installation from moisture.

3. Improper Alignment: Ensure that the F-channel is level and aligned with other components to avoid aesthetic issues. Misalignment can lead to a less professional appearance.

Maintenance of F-Channel Aluminum Extrusions

To keep your F-channel aluminum extrusions looking their best, regular maintenance is essential. Here are some tips:

- Clean Regularly: Use a mild detergent and water to clean the surface of the aluminum. Avoid harsh chemicals that can damage the finish. Regular cleaning will help maintain the appearance and integrity of the aluminum.

- Inspect for Damage: Periodically check for any signs of wear or damage, especially after severe weather. Early detection of issues can prevent more significant problems down the line.

- Reapply Sealant as Needed: Over time, sealant may wear away. Inspect and reapply as necessary to maintain waterproofing. Keeping the sealant fresh will help protect your installation.

Conclusion

Installing F-channel aluminum extrusions can enhance the durability and appearance of your construction project. By following the steps outlined in this guide, you can ensure a successful installation that will stand the test of time. Remember to take your time, measure accurately, and follow best practices for a professional finish.

Frequently Asked Questions

1. What is the best way to cut F-channel aluminum extrusions?

Using a miter saw or hacksaw for clean cuts is recommended. Always wear safety gear to protect yourself during the cutting process.

2. Can I install F-channel aluminum extrusions on uneven surfaces?

It is best to level the surface before installation to ensure proper alignment. Uneven surfaces can lead to complications during installation.

3. How do I choose the right size F-channel for my project?

Consider the weight and type of materials you will be supporting, and consult manufacturer specifications for guidance on selecting the appropriate size.

4. Is sealant necessary for indoor installations?

While not always necessary, using sealant can help prevent moisture issues in humid environments. It is a good practice to use sealant whenever possible.

5. How often should I inspect my F-channel installations?

It is advisable to inspect them at least once a year or after severe weather events. Regular inspections can help identify potential issues early.

By following this comprehensive guide, you can confidently install F-channel aluminum extrusions, ensuring a durable and visually appealing result for your construction projects.