Content Menu

● Understanding Aluminum Extrusion End Caps

>> Types of Aluminum Extrusion End Caps

● Tools and Materials Needed

● Step-by-Step Installation Process

>> Step 1: Measure and Mark

>> Step 2: Prepare the End Caps

>> Step 3: Position the End Caps

>> Step 4: Secure the End Caps

>> Step 5: Inspect the Installation

● Tips for Successful Installation

● Common Mistakes to Avoid

● Maintenance of Aluminum Extrusion End Caps

● Additional Considerations

● Conclusion

● Frequently Asked Questions

>> 1. What Are Aluminum Extrusion End Caps Made Of?

>> 2. Can I Use End Caps on Any Aluminum Extrusion?

>> 3. How Do I Remove End Caps?

>> 4. Are There Custom Options for End Caps?

>> 5. What Should I Do If My End Caps Don't Fit?

Aluminum extrusions are widely used in various industries due to their lightweight, strength, and versatility. One essential component of aluminum extrusions is the end cap, which serves multiple purposes, including protecting the ends of the extrusions, enhancing aesthetics, and providing structural integrity. In this article, we will explore the proper installation of aluminum extrusion end caps, the tools required, and tips for ensuring a secure fit.

Understanding Aluminum Extrusion End Caps

Aluminum extrusion end caps are designed to fit snugly over the ends of aluminum profiles. They come in various shapes and sizes to accommodate different extrusion types. The primary functions of end caps include:

- Protection: End caps prevent dust, dirt, and moisture from entering the hollow sections of the extrusion, which can lead to corrosion and structural damage.

- Aesthetics: They provide a finished look to the aluminum profile, making it more visually appealing.

- Safety: End caps eliminate sharp edges, reducing the risk of injury during handling.

Types of Aluminum Extrusion End Caps

There are several types of end caps available, including:

1. Standard End Caps: These are the most common type and fit over the end of the extrusion.

2. Snap-On End Caps: These caps snap into place, providing a secure fit without the need for additional fasteners.

3. Screw-On End Caps: These require screws for installation, offering a more permanent solution.

4. Custom End Caps: Tailored to specific applications, these caps can be designed to meet unique requirements.

Tools and Materials Needed

Before starting the installation process, gather the following tools and materials:

- End Caps: Ensure you have the correct size and type for your aluminum extrusion.

- Measuring Tape: For accurate measurements.

- Marker or Pencil: To mark the installation points.

- Drill: If using screw-on end caps, a drill will be necessary.

- Screws: Appropriate screws for securing the end caps.

- Safety Gear: Gloves and safety glasses to protect yourself during installation.

Step-by-Step Installation Process

Step 1: Measure and Mark

Begin by measuring the length of the aluminum extrusion to determine where the end caps will be installed. Use a measuring tape to ensure accuracy, and mark the installation points with a marker or pencil. This step is crucial as it ensures that the end caps will fit properly and align with the extrusion.

Step 2: Prepare the End Caps

If you are using snap-on end caps, ensure they are clean and free from debris. For screw-on end caps, pre-drill holes in the end caps if necessary. This will make it easier to secure them to the extrusion. Proper preparation of the end caps can save time during installation and ensure a better fit.

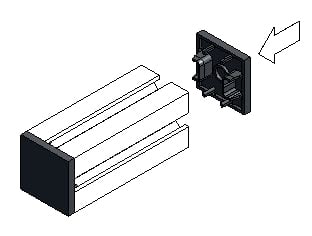

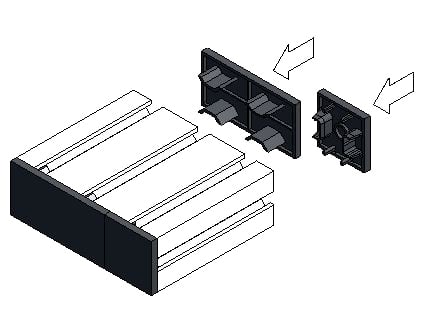

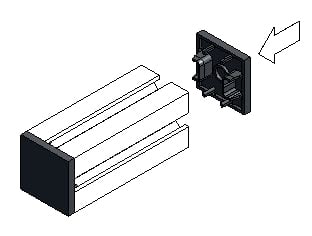

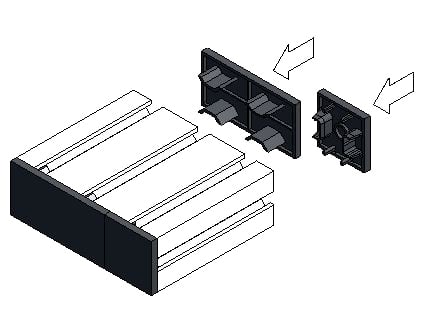

Step 3: Position the End Caps

Align the end caps with the marked points on the aluminum extrusion. For snap-on caps, simply press them onto the ends of the extrusion until they click into place. For screw-on caps, position them over the end of the extrusion. Make sure that the caps are oriented correctly, as some designs may have a specific front and back.

Step 4: Secure the End Caps

For snap-on end caps, ensure they are firmly attached by giving them a gentle tug. For screw-on end caps, use a drill to insert screws into the pre-drilled holes. Make sure the screws are tight but avoid over-tightening, which can damage the cap or the extrusion. A secure fit is essential to prevent the caps from coming loose over time.

Step 5: Inspect the Installation

After securing the end caps, inspect the installation to ensure a proper fit. Check for any gaps or misalignments. If necessary, adjust the caps to achieve a snug fit. A thorough inspection can help identify any issues before they become problematic.

Tips for Successful Installation

- Choose the Right End Caps: Ensure that the end caps you select are compatible with your specific aluminum extrusion profile. Mismatched caps can lead to poor performance and aesthetics.

- Use Quality Materials: Invest in high-quality end caps and screws to ensure durability and longevity. Cheap materials may fail prematurely, leading to additional costs.

- Follow Manufacturer Instructions: Always refer to the manufacturer's guidelines for installation, as different products may have specific requirements. This can help avoid common pitfalls.

- Practice Safety: Wear safety gear and work in a well-ventilated area to avoid accidents. Safety should always be a priority when working with tools and materials.

Common Mistakes to Avoid

1. Incorrect Measurements: Always double-check your measurements to avoid purchasing the wrong size end caps. A small error can lead to significant issues during installation.

2. Neglecting Surface Preparation: Ensure that the ends of the aluminum extrusion are clean and free from debris before installation. Dirt and grime can interfere with the fit.

3. Over-tightening Screws: This can lead to damage to the end caps or the extrusion itself. It's important to find the right balance when securing the caps.

4. Ignoring Aesthetics: Take the time to choose end caps that complement the overall design of your project. A well-finished look can enhance the overall appeal of your work.

Maintenance of Aluminum Extrusion End Caps

To ensure the longevity of your aluminum extrusion end caps, regular maintenance is essential. Here are some tips:

- Clean Regularly: Wipe down the end caps with a damp cloth to remove dust and dirt. Regular cleaning can prevent buildup that may lead to corrosion.

- Inspect for Damage: Periodically check for cracks or wear and replace any damaged caps promptly. Early detection can prevent further issues.

- Reapply Sealant: If your end caps are exposed to harsh weather conditions, consider applying a sealant to enhance protection. This can help extend the life of the caps.

Additional Considerations

When working with aluminum extrusions and end caps, consider the following:

- Environmental Factors: If your project will be exposed to extreme weather conditions, choose end caps that are specifically designed for outdoor use. Some materials may degrade faster when exposed to UV light or moisture.

- Compatibility with Other Components: If your aluminum extrusion is part of a larger assembly, ensure that the end caps do not interfere with other components. This is particularly important in mechanical applications.

- Cost vs. Quality: While it may be tempting to choose cheaper options, investing in quality end caps can save you money in the long run by reducing the need for replacements.

Conclusion

Installing aluminum extrusion end caps is a straightforward process that can significantly enhance the functionality and appearance of your aluminum profiles. By following the steps outlined in this article and avoiding common mistakes, you can ensure a successful installation. Remember to choose the right end caps, use quality materials, and maintain them regularly for optimal performance.

Frequently Asked Questions

1. What Are Aluminum Extrusion End Caps Made Of?

Aluminum extrusion end caps are typically made from aluminum or plastic, depending on the application and desired aesthetics. Aluminum caps are more durable, while plastic caps may be lighter and less expensive.

2. Can I Use End Caps on Any Aluminum Extrusion?

End caps are designed to fit specific aluminum profiles, so it's essential to choose caps that match your extrusion type. Always check compatibility before purchasing.

3. How Do I Remove End Caps?

For snap-on caps, gently pull them off. For screw-on caps, simply unscrew them using a drill or screwdriver. If the caps are stuck, a gentle twist may help loosen them.

4. Are There Custom Options for End Caps?

Yes, many manufacturers offer custom end caps tailored to specific dimensions and requirements. This is particularly useful for unique projects or applications.

5. What Should I Do If My End Caps Don't Fit?

If your end caps don't fit, double-check the measurements and ensure you have the correct type for your aluminum extrusion. If necessary, consult with the supplier for assistance.

By following the guidelines and tips provided in this article, you can successfully install aluminum extrusion end caps and ensure that your projects are both functional and visually appealing.