Content Menu

● Introduction to Plastic Extrusion Machinery

>> Components of Plastic Extrusion Machinery

>> Functionality and Applications

● Finding the Best Deals in NYC

>> Tips for Buying Plastic Extrusion Machinery

● Advanced Considerations

>> Energy Efficiency and Sustainability

>> Automation and Control Systems

>> Maintenance and Repair

● Leveraging Technology for Better Deals

>> Online Research Tools

>> Industry Reports and Trends

● The Role of Local Suppliers

>> Benefits of Local Suppliers

● Conclusion

● FAQs

>> 1. What types of plastic can be used in extrusion machinery?

>> 2. How do I choose the right extruder for my needs?

>> 3. What are the advantages of plastic extrusion?

>> 4. Can I reuse plastic that does not meet specifications?

>> 5. Where can I find plastic extrusion machinery in NYC?

● Citations:

In the bustling city of New York, finding the best deals on plastic extrusion machinery can be a challenging task, especially for those new to the industry. Plastic extrusion machinery is crucial for manufacturing a wide range of products, from pipes and tubing to sheets and profiles. This article will guide you through the process of sourcing the best plastic extrusion machinery in NYC, highlighting key considerations and tips for securing the most cost-effective options.

Introduction to Plastic Extrusion Machinery

Plastic extrusion is a high-volume manufacturing process that transforms raw plastic materials into continuous profiles. The process involves melting plastic pellets and forcing them through a die to create the desired shape. This versatility makes plastic extrusion machinery essential across various industries, including construction, packaging, automotive, and medical sectors.

Components of Plastic Extrusion Machinery

A typical plastic extrusion machine consists of several key components:

- Hopper: Where raw plastic material is loaded.

- Barrel: Houses the extruder screw and is equipped with heaters.

- Extruder Screw: Rotates to melt the plastic through friction and heat.

- Heaters: Aid in maintaining the necessary temperature.

- Die: Shapes the molten plastic into the desired profile.

- Cooling System: Cools and solidifies the extruded product.

- Cutter: Cuts the product into required lengths.

Functionality and Applications

Plastic extrusion machinery is highly versatile, allowing for the production of a wide range of products:

- Pipes and Tubing: Used in plumbing, irrigation systems, and industrial applications.

- Sheets and Films: Common in packaging materials, such as plastic bags and wraps.

- Profiles: Include window frames, door frames, and other building components.

- Cable Insulation: Protects electrical cables from environmental factors.

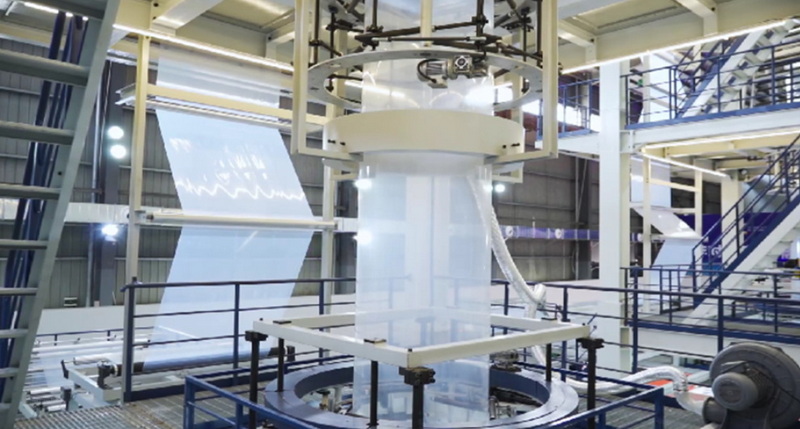

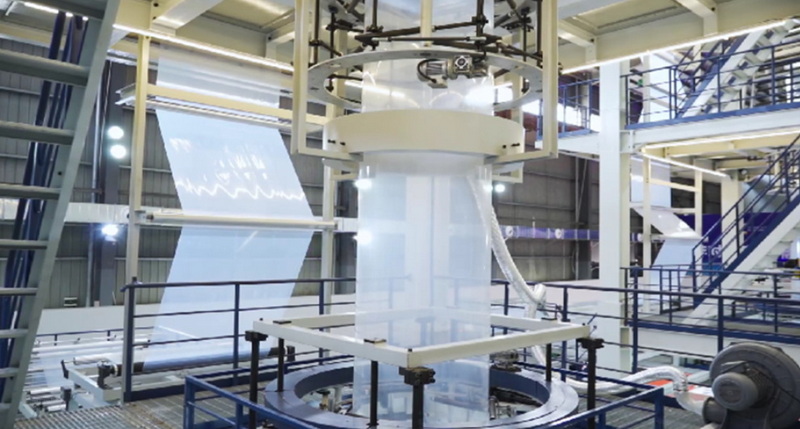

Plastic Extrusion Machinery in Action

Imagine a production line where plastic pellets are fed into a hopper, melted, and then extruded into long, continuous profiles. This process is both efficient and cost-effective, making it a cornerstone of modern manufacturing.

Finding the Best Deals in NYC

To find the best deals on plastic extrusion machinery in NYC, consider the following strategies:

1. Research Local Suppliers: Companies like Plastic Machinery of New York, Inc. offer a wide range of new and used machinery. They provide comprehensive services, including appraisals, liquidations, and auctions, making them a valuable resource for sourcing equipment.

2. Online Marketplaces: Websites like Plastic Machinery & Parts offer a broad selection of new and used plastic extruders from renowned brands. They provide repair services and parts, ensuring you can maintain your machinery effectively.

3. Auctions and Sales: Keep an eye on local auctions and sales events. Although not traditional auctions, platforms like CIA Industrial list machinery at fixed prices, offering a straightforward purchasing experience.

4. Networking: Attend industry events and conferences to connect with suppliers and manufacturers directly. This can lead to exclusive deals and better understanding of the machinery's capabilities.

5. Refurbished Machinery: Consider purchasing refurbished or used machinery. It can be more cost-effective while still offering reliable performance.

Tips for Buying Plastic Extrusion Machinery

When purchasing plastic extrusion machinery, consider the following tips:

- Assess Your Needs: Determine the type of plastic you will be working with and the desired output.

- Check Machinery Specifications: Ensure the machinery can handle your production volume and material types.

- Warranty and Support: Look for suppliers offering comprehensive warranties and maintenance support.

- Inspect Before Purchase: If possible, inspect the machinery before buying, especially for used equipment.

Advanced Considerations

Energy Efficiency and Sustainability

Modern plastic extrusion machinery often incorporates energy-efficient technologies, such as advanced heating systems and optimized screw designs. These improvements not only reduce operational costs but also contribute to a more sustainable manufacturing process.

Automation and Control Systems

Many contemporary plastic extruders come equipped with sophisticated automation and control systems. These systems enhance precision, consistency, and productivity by allowing for real-time monitoring and adjustments during the extrusion process.

Maintenance and Repair

Regular maintenance is crucial for extending the lifespan of plastic extrusion machinery. Ensure that you have access to spare parts and skilled technicians who can perform repairs efficiently.

Leveraging Technology for Better Deals

In today's digital age, leveraging technology can significantly enhance your search for the best deals on plastic extrusion machinery:

Online Research Tools

Utilize online directories and forums to gather information about suppliers, machinery specifications, and customer reviews. This can help you make informed decisions and avoid potential pitfalls.

Industry Reports and Trends

Stay updated on industry trends and reports to understand market fluctuations and emerging technologies. This knowledge can help you negotiate better prices and invest in machinery that aligns with future demands.

The Role of Local Suppliers

Local suppliers play a vital role in providing personalized service and support. They often have a deep understanding of the local market and can offer tailored solutions to meet specific needs.

Benefits of Local Suppliers

- Quick Response Times: Local suppliers can respond quickly to maintenance requests and provide immediate support.

- Customized Solutions: They can offer customized machinery configurations based on your specific production requirements.

- Community Involvement: Supporting local businesses contributes to the local economy and fosters community growth.

Conclusion

Finding the best deals on plastic extrusion machinery in NYC requires thorough research, networking, and a clear understanding of your production needs. By leveraging local suppliers, online marketplaces, and auctions, you can secure cost-effective options that meet your manufacturing requirements. Additionally, embracing technology for market research and staying updated on industry trends can further enhance your purchasing decisions.

FAQs

Here are some frequently asked questions related to plastic extrusion machinery in NYC:

1. What types of plastic can be used in extrusion machinery?

- Common types include PVC, HDPE, polypropylene, and polycarbonate. Each has specific properties suitable for different applications.

2. How do I choose the right extruder for my needs?

- Consider the type of plastic, desired output, and application. Single-screw or twin-screw extruders may be more suitable based on your production requirements.

3. What are the advantages of plastic extrusion?

- Plastic extrusion offers efficiency, versatility, and the ability to produce high volumes consistently. It is widely used across various industries.

4. Can I reuse plastic that does not meet specifications?

- Yes, many manufacturers can grind and reuse scrap plastic in the extrusion process, reducing waste and increasing sustainability.

5. Where can I find plastic extrusion machinery in NYC?

- Companies like Plastic Machinery of New York, Inc. and online platforms like Plastic Machinery & Parts are good starting points for sourcing machinery in NYC.

Citations:

[1] http://www.plasticmachinerysales.com/category/464/Plastic-Extrusion-Equipment.html

[2] https://www.cia-industrial.com/auction/high-quality-plastic-extrusion-equipment/

[3] https://www.istockphoto.com/photos/plastic-extrusion-machine

[4] https://www.youtube.com/watch?v=qn16JtE_vLc

[5] https://plasticextrusiontech.net/our-process/

[6] https://berlinplastics.com/faqs/

[7] https://pemsinc.com

[8] https://plasticextrusiontech.net

[9] https://jieyatwinscrew.com/blog/everything-you-need-to-know-about-plastic-extrusion-machines/

[10] https://jieyatwinscrew.com/blog/the-ultimate-guide-to-plastic-extrusion-and-choosing-the-right-extruder-machine/

[11] https://www.thomasnet.com/suppliers/usa/plastics-extrusion-equipment-96202767

[12] https://plastiwin.com/buy-used-plastic-processing-equipment/used-plastic/

[13] https://www.pemusa.com

[14] https://plasticfabricator.com/category/new-york/

[15] https://www.arlingtonmachinery.com/plastic-extruder/

[16] https://davis-standard.com

[17] https://www.jwellmachine.com

[18] https://www.imarcgroup.com/plastic-extrusion-machines-market

[19] https://plastic-tubing.biz/precision-extrusion-inc/

[20] https://www.rdnmfg.com/turnkey-extrusion-equipment/

[21] https://pemsinc.com/inventory/

[22] https://hunterplastics.com/product-category/extrusion/extrusion-downstream

[23] https://www.youtube.com/watch?v=zBrp7Li0K4Y

[24] https://www.youtube.com/watch?v=GxgG7inFQKw

[25] https://www.youtube.com/channel/UCxbvt08kCDNZbqrZhuJzhBA?view_as=subscriber

[26] http://www.industrialextrusionmachinery.com/plastic_extrusion_machines.html

[27] https://www.gettyimages.ca/photos/plastics-extrusion-machine

[28] https://www.youtube.com/watch?v=M7qiNYDGU68

[29] https://jieyatwinscrew.com/blog/the-ultimate-guide-to-plastic-extruder-machines/