Content Menu

● Introduction to Fully Automatic Extrusion Machines

>> Key Components of a Fully Automatic Extrusion Machine

● Factors Affecting the Price of a Fully Automatic Extrusion Machine

>> High Quality Fully Automatic Extrusion Machine Pricelist

● How to Get a Quote for a Fully Automatic Extrusion Machine

>> Example of a Quote Request Form

● Advanced Features in Modern Extrusion Machines

>> Case Study: IBC Three Layer Co-Extrusion Machine

>> Case Study: Exelliq's DIGI.LINE

● Maintenance and Upkeep of Extrusion Machines

● Applications of Fully Automatic Extrusion Machines

>> Environmental Impact

● Conclusion

● FAQ

>> 1. What are the key factors affecting the price of a fully automatic extrusion machine?

>> 2. How do I ensure the quality of a fully automatic extrusion machine?

>> 3. What types of plastic products can be produced with a fully automatic extrusion machine?

>> 4. How long does it typically take to receive a quote for a fully automatic extrusion machine?

>> 5. Are there any additional costs associated with purchasing a fully automatic extrusion machine?

● Citations:

In the modern manufacturing landscape, fully automatic extrusion machines play a crucial role in producing a wide range of plastic products efficiently and cost-effectively. These machines are designed to automate the entire extrusion process, from material feeding to final product shaping, ensuring consistency and high-quality output. If you are interested in acquiring a fully automatic extrusion machine, understanding how to obtain a quote is essential. This article will guide you through the process and provide insights into the factors affecting the pricing of these machines.

Introduction to Fully Automatic Extrusion Machines

Fully automatic extrusion machines are sophisticated systems that integrate advanced technologies to streamline the production of plastic products such as pipes, profiles, sheets, and films. These machines are equipped with features like automated material feeding, temperature control, and precision die shaping, ensuring that the final products meet precise specifications.

Key Components of a Fully Automatic Extrusion Machine

1. Hopper: Serves as the material reservoir, feeding raw plastic into the machine.

2. Barrel and Screw: The barrel houses the screw, which conveys, compresses, and melts the plastic.

3. Heating Elements: These elements, such as electric heaters or steam jackets, raise the material's temperature for processing.

4. Die: Shapes the molten plastic into the desired form as it exits the machine.

Factors Affecting the Price of a Fully Automatic Extrusion Machine

The cost of a fully automatic extrusion machine can vary significantly based on several factors:

- Machine Type: Different types of extrusion machines (e.g., pipe, profile, sheet) have varying complexities and prices.

- Production Capacity: Machines with higher output capacities are generally more expensive.

- Material Handling Capabilities: Machines designed to handle a variety of materials or high-performance plastics are more costly.

- Technological Features: Advanced automation, energy-efficient motors, and PLC control systems increase the price.

- Customization Options: Tailoring the machine to specific client needs can add to the cost.

High Quality Fully Automatic Extrusion Machine Pricelist

Prices for fully automatic extrusion machines can range from $50,000 to over $500,000, depending on the specifications and features. For example:

- Basic Models: Entry-level machines for small-scale production can cost between $50,000 and $100,000.

- Medium-Sized Machines: Suitable for small to medium-scale production, these machines range from $100,000 to $300,000.

- Premium Customized Machines: High-capacity machines with specialized features can cost $300,000 or more.

How to Get a Quote for a Fully Automatic Extrusion Machine

To obtain a quote for a fully automatic extrusion machine, follow these steps:

1. Identify Your Needs: Determine the type of plastic products you want to produce and the desired production capacity.

2. Research Suppliers: Look for reputable manufacturers that offer the type of machine you need.

3. Contact Suppliers: Reach out to selected suppliers via phone, email, or through their website's contact form.

4. Provide Specifications: Share your product specifications, including material type, production volume, and any customization requirements.

5. Request a Quote: Ask for a detailed quote that includes the machine price, delivery time, and any additional costs.

Example of a Quote Request Form

| Field | Description |

| Company Name | Your company name |

| Contact Information | Email and phone number |

| Machine Type | Specify the type of extrusion machine needed |

| Production Capacity | Desired output per hour |

| Material Type | Type of plastic material to be processed |

| Customization Needs | Any special features or modifications required |

Advanced Features in Modern Extrusion Machines

Modern fully automatic extrusion machines often incorporate advanced technologies to enhance efficiency and product quality:

- PLC Control Systems: These systems automate the process, ensuring consistent production and minimizing human error.

- Real-Time Monitoring: Allows for immediate adjustments to be made during production, optimizing output and reducing waste.

- Energy Efficiency: New machines are designed to consume less energy while maintaining high productivity.

Case Study: IBC Three Layer Co-Extrusion Machine

The IBC Three Layer co-extrusion machine is an example of advanced technology in extrusion. It features a high-efficiency extrusion line with an IBC film cooling system, offering higher output and lower energy consumption compared to similar equipment. This machine includes optional devices such as gravimetric dosing systems and film thickness measuring systems, which enhance precision and control over the final product[1].

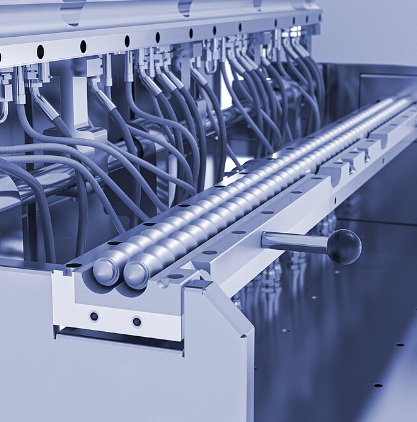

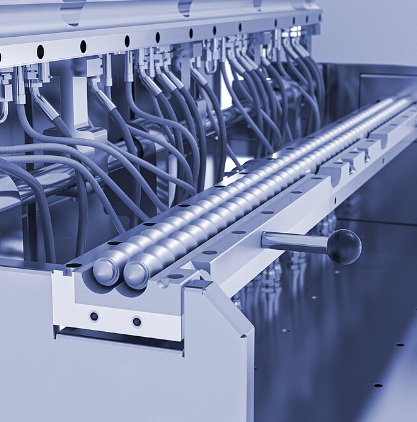

Case Study: Exelliq's DIGI.LINE

Exelliq's DIGI.LINE is another example of innovative extrusion technology. This automated and networked extrusion line controls and optimizes production in real-time, ensuring consistent quality and efficiency. It demonstrates how Industry 4.0 technologies are transforming the extrusion industry by integrating digitalization and automation[3].

Maintenance and Upkeep of Extrusion Machines

Regular maintenance is crucial to ensure the longevity and efficiency of fully automatic extrusion machines. Here are some key tips:

- Clean Electrical Parts: Regularly clean dust from inverters and PLCs to prevent malfunction.

- Monitor Parameters: Keep records of nominal parameters for easy reference during restarts.

- Check Wires: Use multimeters to test for short circuits.

- Lubricate Moving Parts: Regularly apply lubricant to screws, rollers, and axles[5].

Applications of Fully Automatic Extrusion Machines

Fully automatic extrusion machines are used across various industries:

- Plastics Industry: Produces items like pipes, tubes, and packaging materials.

- Metal Industry: Creates aluminum profiles and other metal components.

- Composite Materials: Used in manufacturing pressure tanks and reinforced structures[2].

Environmental Impact

Automatic extrusion offers several environmental benefits:

- Reduced Waste: Automated systems optimize material usage, reducing waste.

- Energy Efficiency: Modern machines are designed to be energy-efficient, reducing the carbon footprint of the manufacturing process[2].

Conclusion

Acquiring a fully automatic extrusion machine is a significant investment for any manufacturing business. Understanding the factors that influence pricing and knowing how to request a quote can help you make informed decisions. Always ensure that the machine aligns with your production needs and budget.

FAQ

1. What are the key factors affecting the price of a fully automatic extrusion machine?

The price of a fully automatic extrusion machine is influenced by factors such as machine type, production capacity, material handling capabilities, technological features, and customization options.

2. How do I ensure the quality of a fully automatic extrusion machine?

To ensure quality, research the supplier's reputation, inspect manufacturing facilities if possible, and request product samples or references from previous clients.

3. What types of plastic products can be produced with a fully automatic extrusion machine?

Fully automatic extrusion machines can produce a variety of plastic products, including pipes, profiles, sheets, and films, depending on the machine's configuration.

4. How long does it typically take to receive a quote for a fully automatic extrusion machine?

The time to receive a quote can vary depending on the supplier and the complexity of your request. Typically, you should receive a quote within a few days to a week after submitting your specifications.

5. Are there any additional costs associated with purchasing a fully automatic extrusion machine?

Yes, additional costs may include installation fees, training for operators, maintenance services, and spare parts. These should be considered when budgeting for the machine.

Citations:

[1] https://shubhamextrusion.com/ibc-three-layer-fully-automatic-high-performance/

[2] https://www.yjing-extrusion.com/what-is-automatic-extrusion-and-how-does-it-work.html

[3] https://www.exelliq.com/en/company/technology-innovation

[4] https://www.tahara-mc.com/en/techinfo2/

[5] https://www.linkedin.com/pulse/jwell-machinery-10-tips-extruder-line-maintenance-thunder-di

[6] https://www.extruders-machine.com/sale-14516959-fully-automatic-350kg-h-double-screw-extrusion-machine.html

[7] https://www.ptonline.com/articles/fully-automated-extrusion-process-enables-use-of-composites-for-manufacturing-pressure-tanks-

[8] https://www.alibaba.com/product-detail/New-Technology-Fully-Automatic-1800-Ton_1600237194749.html

[9] https://www.yjing-extrusion.com/how-to-maintain-and-troubleshoot-a-china-automatic-plastic-extrusion-machine.html

[10] https://www.yjing-extrusion.com/which-fully-automatic-extrusion-machine-is-the-best-for-your-business.html

[11] https://www.moldingmachinetepai.com/resources/plastic-extrusion-machines-introduction-types-application.html

[12] https://szpolywell.en.made-in-china.com/product/CdaAwFZclJhE/China-High-Tech-Fully-Automatic-Nylon-Extrusion-Machine-For-Polyamide-Strips-Plastic-Extruder-Machine.html