Content Menu

● Understanding Aluminum Extrusion CAD Files

● Why Use Aluminum Extrusion CAD Files?

● The Role of CAD Software in Aluminum Extrusion Design

● Where to Find Free Aluminum Extrusion CAD Files

>> 1. GrabCAD

>> 2. 80/20 Inc.

>> 3. 3D ContentCentral

>> 4. TraceParts

>> 5. Capral

● Steps to Download Aluminum Extrusion CAD Files

● Tips for Using Aluminum Extrusion CAD Files

● Best Practices in Aluminum Extrusion Design

>> Utilize Accurate Measurements

>> Verify Material Properties

>> Consider Post-extrusion Processes

>> Communicate Clearly with Suppliers

● Advancements in Aluminum Extrusion Technology

● Applications of Aluminum Extrusions

● Conclusion

● FAQ

>> 1. What file formats are available for aluminum extrusion CAD files?

>> 2. Do I need special software to view these CAD files?

>> 3. Are there any costs associated with downloading these files?

>> 4. Can I modify downloaded aluminum extrusion CAD files?

>> 5. How often are new aluminum extrusion models added to these platforms?

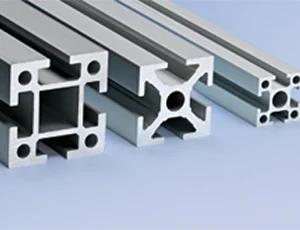

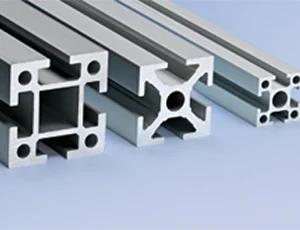

Aluminum extrusions are widely used in various industries for their versatility and strength. Designers and engineers often require CAD files to integrate these components into their projects. Fortunately, there are numerous resources available online where you can download free aluminum extrusion CAD files. This article will guide you through the process, highlighting the best platforms and methods to access these valuable resources.

Understanding Aluminum Extrusion CAD Files

Aluminum extrusion CAD files are digital representations of aluminum profiles created using computer-aided design (CAD) software. These files come in various formats, including DWG, DXF, STEP, and IGES, making them compatible with most CAD programs. They are essential for engineers and designers as they allow for accurate modeling and integration into larger systems.

Why Use Aluminum Extrusion CAD Files?

- Precision Design: CAD files provide exact dimensions and specifications.

- Time Efficiency: Using pre-made designs saves time in the drafting process.

- Customization: Many platforms allow users to modify existing designs to fit specific needs.

- Collaboration: Sharing CAD files enhances teamwork among engineers and designers.

The Role of CAD Software in Aluminum Extrusion Design

CAD software has revolutionized the aluminum extrusion industry by providing tools that enhance design precision and efficiency. Some key benefits include:

- Precision: One of the most significant advantages of CAD is its unparalleled accuracy. Designers can make extremely detailed measurements, which is crucial for the exactness that aluminum extrusion demands.

- Flexibility: If a mistake is made or if a design needs tweaking, modifications can be made quickly without starting from scratch.

- Visualization: CAD provides a 3D perspective, allowing designers to visualize the final product from different angles, ensuring the design is perfect from all viewpoints.

Where to Find Free Aluminum Extrusion CAD Files

Here are some of the best platforms to download free aluminum extrusion CAD files:

1. GrabCAD

GrabCAD is a community-driven platform where users can share and download CAD models, including aluminum extrusions. To find aluminum extrusion files:

- Visit the GrabCAD library.

- Use the search bar to enter "aluminum extrusion."

- Browse through the available models and select the desired file format.

2. 80/20 Inc.

80/20 Inc. offers a comprehensive library of aluminum extrusion profiles and parts. Here's how to access their CAD files:

- Go to the 80/20 website.

- Navigate to the "Tools" section and select "CAD Libraries."

- Choose from various formats available for download.

3. 3D ContentCentral

This platform provides a wide range of 3D models, including aluminum extrusions from multiple suppliers. To download:

- Visit 3D ContentCentral.

- Search for "aluminum frames" or "aluminum extrusions."

- Select the model you need and choose your preferred file format.

4. TraceParts

TraceParts hosts a vast collection of CAD files from different manufacturers, including Bonnell Aluminum's TSLOTS product line. To access these files:

- Go to TraceParts' website.

- Search for "Bonnell Aluminum" or "TSLOTS."

- Download the required CAD file in your desired format.

5. Capral

Capral provides technical documents and CAD files for their aluminum extrusions. To find these resources:

- Visit Capral's website.

- Navigate to the "Downloads" section.

- Select the relevant category to find CAD files.

Steps to Download Aluminum Extrusion CAD Files

1. Choose a Platform: Select one of the mentioned platforms based on your needs.

2. Search for Your Desired Profile: Use specific keywords like “aluminum extrusion” or “T-slot” in the search bar.

3. Select File Format: Ensure you choose a compatible file format for your CAD software.

4. Create an Account (if necessary): Some sites may require you to create a free account before downloading.

5. Download the File: Click on the download button and save it to your device.

Tips for Using Aluminum Extrusion CAD Files

- Check Compatibility: Ensure that the file format is compatible with your CAD software.

- Modify as Needed: Use your CAD software to customize dimensions or features as per your project requirements.

- Keep Updated: Regularly check for updates on platforms as new models are frequently added.

Best Practices in Aluminum Extrusion Design

When working with aluminum extrusions, following best practices can significantly enhance your design outcomes:

Utilize Accurate Measurements

Double-check measurements during design creation to ensure all dimensions meet specifications precisely. This step is crucial as even minor errors can lead to significant issues during manufacturing.

Verify Material Properties

Understanding different aluminum alloys is essential for selecting materials that meet strength, corrosion resistance, and other performance criteria. Some alloys offer better flow characteristics through complex die designs but may not provide high strength.

Consider Post-extrusion Processes

Recognizing how post-extrusion processes affect dimensions and tolerances is vital. For example, cutting tools can exert pressure that may deform thin-walled extrusions if not handled properly.

Communicate Clearly with Suppliers

Effective communication with suppliers ensures that they understand your specifications clearly, which helps avoid potential issues during production.

Advancements in Aluminum Extrusion Technology

The aluminum extrusion process has evolved significantly due to advancements in technology:

- Computer-Aided Manufacturing (CAM): Integrating CAM with CAD allows for seamless transitions from design to production, minimizing errors and enhancing efficiency.

- Simulation Tools: Modern CAD software often includes simulation capabilities that enable designers to test how their designs will perform under real-world conditions before manufacturing begins.

- Internet of Things (IoT): IoT technology is being utilized in manufacturing setups where equipment can track material usage, pressure levels during extrusion, and even adjust parameters remotely in real-time.

Applications of Aluminum Extrusions

Aluminum extrusions have numerous applications across various industries due to their lightweight yet strong characteristics:

- Aerospace: Used extensively for structural components due to their strength-to-weight ratio.

- Automotive: Employed in vehicle frames and components where reducing weight without sacrificing strength is critical.

- Construction: Commonly used in window frames, door frames, and other structural elements.

- Electronics: Utilized in enclosures and heat sinks due to their excellent thermal conductivity.

- Renewable Energy: Found in solar panel frames and mounting systems because of their durability against environmental factors.

Conclusion

Downloading free aluminum extrusion CAD files is straightforward if you know where to look. Platforms like GrabCAD, 80/20 Inc., 3D ContentCentral, TraceParts, and Capral provide extensive libraries of high-quality models that can enhance your design process significantly. By following the steps outlined in this article, you can efficiently access these resources and integrate them into your projects with ease while adhering to best practices that ensure successful outcomes in aluminum extrusion design.

FAQ

1. What file formats are available for aluminum extrusion CAD files?

Most platforms offer various formats such as DWG, DXF, STEP, IGES, and STL.

2. Do I need special software to view these CAD files?

Yes, you will need a compatible CAD program like AutoCAD, SolidWorks, or similar software that supports the file formats provided.

3. Are there any costs associated with downloading these files?

The resources mentioned in this article offer free downloads; however, some may require account creation.

4. Can I modify downloaded aluminum extrusion CAD files?

Yes, once downloaded, you can modify them using your preferred CAD software according to your project requirements.

5. How often are new aluminum extrusion models added to these platforms?

Many platforms regularly update their libraries with new models; checking back frequently can help you find fresh designs.