Content Menu

● Understanding Aluminum Extrusions

>> Why Cut at a 45-Degree Angle?

● Tools Required for Cutting Aluminum Extrusions

● Preparing for the Cut

● Making the Cut

>> Tips for a Clean Cut

● Common Mistakes to Avoid

● Advanced Techniques for Cutting Aluminum Extrusions

>> Using a CNC Machine

>> Creating Custom Jigs

>> Experimenting with Different Angles

● Conclusion

● Frequently Asked Questions

>> 1. What is the best tool for cutting aluminum extrusions?

>> 2. Can I use a regular saw to cut aluminum?

>> 3. How do I prevent aluminum from bending while cutting?

>> 4. What should I do if the cut is not straight?

>> 5. Is it necessary to deburr the edges after cutting?

Cutting aluminum extrusions at a 45-degree angle is a common task in various industries, including construction, manufacturing, and DIY projects. Whether you are building a frame, creating a custom piece of furniture, or working on a specialized project, understanding how to make precise cuts is essential for achieving professional results. This article will guide you through the process of cutting aluminum extrusions accurately, the tools you will need, and tips to ensure your cuts are clean and precise.

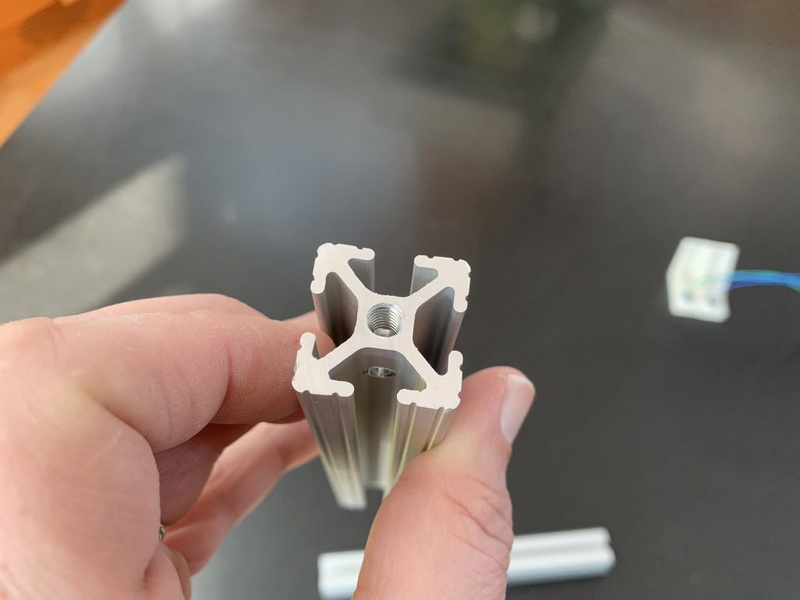

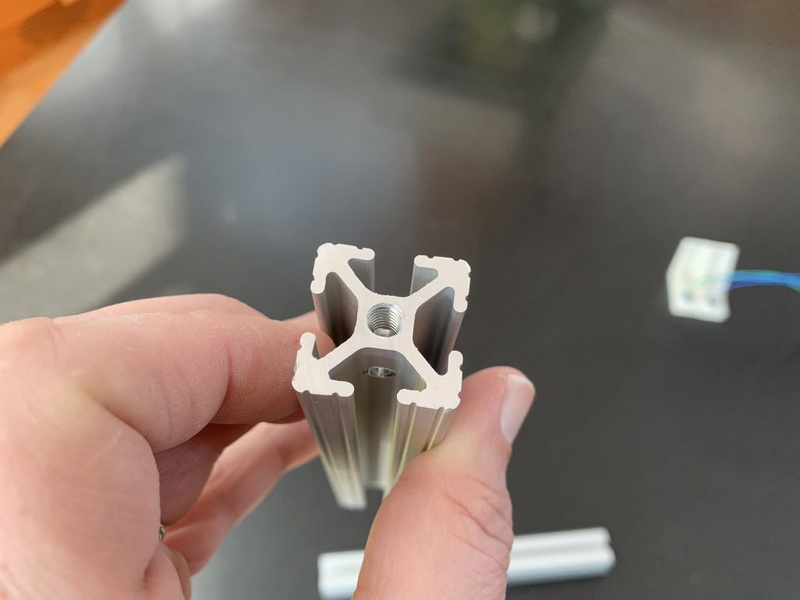

Understanding Aluminum Extrusions

Aluminum extrusions are created by forcing aluminum alloy through a die to create a specific cross-sectional shape. This process allows for a wide variety of profiles, including angles, channels, and tubes, which can be used in numerous applications. The lightweight nature of aluminum, combined with its strength and resistance to corrosion, makes it a popular choice for many projects.

Why Cut at a 45-Degree Angle?

Cutting aluminum extrusions at a 45-degree angle is often necessary for creating joints, frames, and other structures that require a snug fit. This angle is commonly used in miter joints, which are essential for achieving a clean and professional look in projects such as picture frames, window frames, and cabinetry. A 45-degree cut allows two pieces to meet at a corner, creating a seamless appearance that enhances the overall aesthetic of the project.

Tools Required for Cutting Aluminum Extrusions

To cut aluminum extrusions accurately at a 45-degree angle, you will need the following tools:

1. Miter Saw: A miter saw is one of the best tools for making precise angled cuts. It allows you to set the angle easily and provides a clean cut.

2. Table Saw: If you have a table saw with a miter gauge, you can also use it to cut aluminum extrusions. Ensure that the blade is suitable for cutting metal.

3. Band Saw: A band saw can be used for cutting aluminum extrusions, especially for thicker profiles. It provides good control and can handle various shapes.

4. Chop Saw: A chop saw, or abrasive saw, is another option for cutting aluminum. It is particularly useful for larger pieces and can make quick work of cutting through metal.

5. Measuring Tools: A tape measure, square, and marking tools are essential for measuring and marking your cuts accurately.

6. Clamps: To ensure safety and precision, use clamps to secure the aluminum extrusion while cutting.

7. Safety Gear: Always wear safety glasses and gloves when cutting aluminum to protect yourself from metal shavings and sharp edges.

Preparing for the Cut

Before you begin cutting, it's crucial to prepare your workspace and the aluminum extrusion:

1. Measure and Mark: Use a tape measure to determine the length of the cut. Mark the cut line clearly with a pencil or marker. For a 45-degree cut, you can use a speed square to mark the angle accurately.

2. Secure the Workpiece: Use clamps to secure the aluminum extrusion to your workbench or cutting surface. This will prevent movement during the cut and ensure a clean finish.

3. Set Up the Saw: Adjust your miter saw or table saw to a 45-degree angle. Double-check the angle using a protractor or miter gauge to ensure accuracy.

Making the Cut

Now that you are prepared, it's time to make the cut:

1. Position the Extrusion: Place the aluminum extrusion against the saw's fence, aligning the marked line with the blade. Ensure that the extrusion is flat and stable.

2. Start the Saw: Turn on the saw and allow the blade to reach full speed before making contact with the aluminum.

3. Make the Cut: Slowly lower the blade onto the extrusion, applying steady pressure. Do not force the blade; let it do the work. If you are using a chop saw, ensure that you are using the correct cutting speed and technique.

4. Finish the Cut: Once the cut is complete, lift the blade and turn off the saw. Allow the blade to come to a complete stop before removing the aluminum piece.

Tips for a Clean Cut

- Use the Right Blade: Ensure that you are using a blade designed for cutting aluminum. A fine-toothed blade will provide a smoother cut and reduce the risk of burrs.

- Lubricate the Blade: Applying a lubricant, such as cutting oil, can help reduce friction and heat, resulting in a cleaner cut.

- Cut Slowly: Rushing the cut can lead to mistakes and a rough finish. Take your time to ensure accuracy.

- Deburr the Edges: After cutting, use a deburring tool or file to smooth any sharp edges. This will improve the appearance and safety of your project.

Common Mistakes to Avoid

1. Incorrect Measurements: Always double-check your measurements before cutting. A small mistake can lead to significant issues in your project.

2. Not Securing the Workpiece: Failing to secure the aluminum extrusion can result in uneven cuts and potential injury.

3. Using the Wrong Blade: Using a blade not designed for aluminum can lead to poor cuts and damage to the material.

4. Rushing the Cut: Cutting too quickly can cause the blade to bind or create a rough edge. Take your time for the best results.

Advanced Techniques for Cutting Aluminum Extrusions

Once you are comfortable with basic cutting techniques, you may want to explore more advanced methods to enhance your skills:

Using a CNC Machine

For those involved in larger-scale projects or requiring high precision, a CNC (Computer Numerical Control) machine can be an excellent investment. CNC machines can be programmed to make complex cuts and shapes, including 45-degree angles, with incredible accuracy. This method is particularly useful for repetitive tasks, as it ensures consistency across multiple pieces.

Creating Custom Jigs

If you frequently cut aluminum extrusions at specific angles, consider creating a custom jig. A jig can help you maintain the correct angle and position for each cut, reducing setup time and increasing accuracy. You can build a simple jig using scrap wood or metal, ensuring it securely holds the extrusion in place while you cut.

Experimenting with Different Angles

While 45-degree cuts are common, don't hesitate to experiment with other angles for different applications. Understanding how to cut at various angles can expand your capabilities and allow for more creative designs in your projects.

Conclusion

Cutting aluminum extrusions at a 45-degree angle accurately is a skill that can greatly enhance the quality of your projects. By using the right tools, preparing properly, and following best practices, you can achieve clean and precise cuts every time. Whether you are a professional or a DIY enthusiast, mastering this technique will open up new possibilities for your work.

Frequently Asked Questions

1. What is the best tool for cutting aluminum extrusions?

The best tool depends on the thickness and type of aluminum extrusion. A miter saw is ideal for most applications, while a band saw is better for thicker profiles.

2. Can I use a regular saw to cut aluminum?

While you can use a regular saw, it is recommended to use a saw specifically designed for cutting metal to achieve better results.

3. How do I prevent aluminum from bending while cutting?

Secure the aluminum extrusion firmly with clamps and ensure that you are using the correct cutting technique to minimize bending.

4. What should I do if the cut is not straight?

If the cut is not straight, check your measurements and the alignment of the extrusion. You may need to adjust your setup and try again.

5. Is it necessary to deburr the edges after cutting?

Yes, deburring the edges is important for safety and aesthetics. It helps to remove sharp edges that could cause injury.