Content Menu

● Understanding Your Production Requirements

● Key Factors for Selecting a Pipe Extrusion Equipment Supplier

>> Track Record and Industry Experience

>> Quality of Machinery and Components

>> Customization and Technical Flexibility

>> Certifications and Regulatory Compliance

>> After-Sales Service and Support

>> Reputation and Customer Feedback

>> Energy Efficiency and Operational Costs

>> Delivery, Warranty, and Pricing Transparency

● Evaluating the Supplier's Product Range

● Importance of Innovation and Technology

● Building a Long-Term Partnership

● Additional Considerations When Choosing a Pipe Extrusion Equipment Supplier

>> Technical Support and Training

>> Spare Parts Availability

>> Financial Stability and Business Ethics

>> Global Reach and Local Presence

● Conclusion

● FAQ

>> 1. What certifications should a reliable pipe extrusion equipment supplier have?

>> 2. How important is after-sales support when choosing a pipe extrusion equipment supplier?

>> 3. Can a pipe extrusion equipment supplier customize machinery for specific production needs?

>> 4. What role does energy efficiency play in selecting a pipe extrusion equipment supplier?

>> 5. How can I assess the reputation of a pipe extrusion equipment supplier?

Choosing the best pipe extrusion equipment supplier is a critical decision for any manufacturer in the plastics industry. This choice has a direct impact on your product quality, production efficiency, and the long-term success of your business. With many suppliers available in the global market, each offering a range of technologies and services, it can be challenging to determine which supplier will best meet your needs. This comprehensive guide will walk you through the essential factors to consider, helping you make a confident and informed decision.

Understanding Your Production Requirements

Before you begin evaluating pipe extrusion equipment suppliers, it is vital to clearly define your own production needs. This step will help you identify suppliers whose equipment and expertise align with your specific requirements. Consider the following aspects:

- Pipe Types and Materials: Determine whether you will be producing pipes from PVC, HDPE, PPR, or other materials. Each material may require different extrusion technologies.

- Pipe Sizes and Specifications: Outline the range of pipe diameters, wall thicknesses, and tolerances you need to achieve.

- Production Volumes: Estimate your expected output, both in terms of daily capacity and long-term scalability.

- Automation and Integration: Decide on the level of automation you require, and whether the equipment must integrate with existing systems.

- Future Flexibility: Consider whether you may need to diversify your product range or expand your facility in the future.

Having a clear understanding of these parameters will streamline your search for the ideal pipe extrusion equipment supplier.

Key Factors for Selecting a Pipe Extrusion Equipment Supplier

Track Record and Industry Experience

A supplier's history and experience in the industry speak volumes about their reliability and expertise. Look for a pipe extrusion equipment supplier with a solid track record of successful installations and satisfied customers. An experienced supplier is more likely to have refined their manufacturing processes, developed robust support systems, and adapted to evolving industry standards. Their accumulated knowledge can be invaluable in troubleshooting challenges and optimizing your production lines.

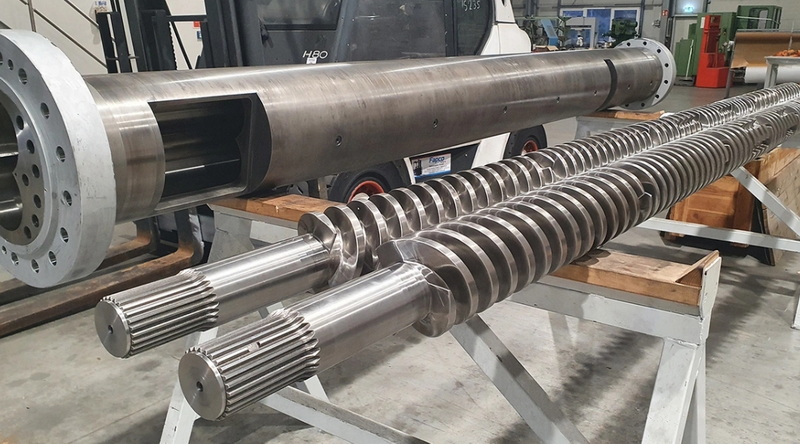

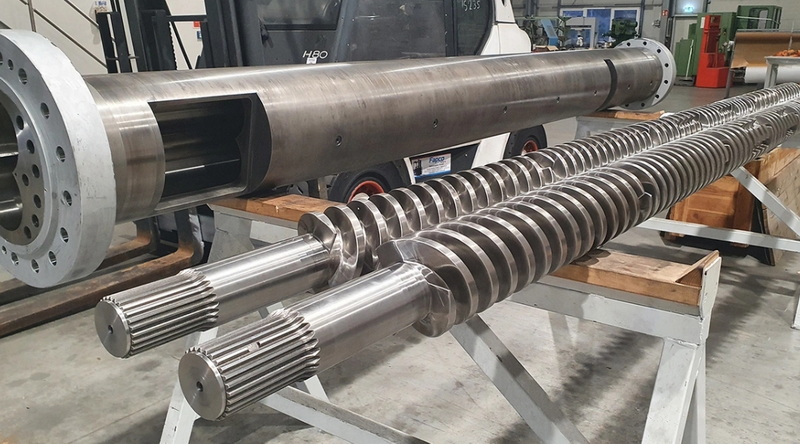

Quality of Machinery and Components

The performance and longevity of your extrusion line depend heavily on the quality of the machinery and its components. Leading pipe extrusion equipment suppliers use high-grade, globally recognized brands for critical parts such as motors, gearboxes, control panels, and electronics. This ensures reliable operation and makes maintenance easier, as replacement parts are widely available.

Key aspects to assess include:

- Precision Engineering: Screws and barrels should be engineered for uniform material flow and consistent output.

- Advanced Controls: Look for modern temperature and process control systems that deliver stable and repeatable results.

- Durable Construction: Equipment should be built from robust, anti-corrosive materials to withstand years of continuous use.

- Modular Design: Modular systems allow for easy upgrades and maintenance, supporting future expansion.

Customization and Technical Flexibility

Every manufacturing operation has unique needs, and a one-size-fits-all approach rarely delivers optimal results. The best pipe extrusion equipment supplier will offer customizable solutions, allowing you to tailor machinery specifications to your production requirements. This might include:

- Adjustable screw and barrel configurations for processing different materials

- Die heads that accommodate a variety of pipe sizes and wall thicknesses

- Integration with downstream equipment such as vacuum tanks, cooling baths, haul-offs, and cutters

- Automation features for process monitoring, data collection, and remote diagnostics

Suppliers who demonstrate technical flexibility are better equipped to support your evolving production goals.

Certifications and Regulatory Compliance

It is essential to verify that your chosen supplier adheres to recognized international quality standards. Certifications such as ISO 9001 for quality management and CE marking for safety compliance demonstrate a commitment to quality, safety, and regulatory adherence. Working with a certified pipe extrusion equipment supplier reduces the risk of equipment failure, safety incidents, and non-compliance with industry regulations.

After-Sales Service and Support

Comprehensive after-sales support is a hallmark of a top-tier pipe extrusion equipment supplier. Quality suppliers provide:

- Technical assistance during installation and commissioning

- Operator training and ongoing education

- Rapid response to troubleshooting and repair requests

- Readily available spare parts and consumables

- Preventive maintenance programs

Strong after-sales service minimizes downtime, extends equipment lifespan, and maximizes your return on investment.

Reputation and Customer Feedback

Research the supplier's reputation within the industry. Seek out customer testimonials, case studies, and independent reviews. A supplier with a reputation for reliability, transparency, and customer satisfaction is more likely to deliver a positive experience. Don't hesitate to request references or visit existing installations to see the equipment in operation.

Energy Efficiency and Operational Costs

Energy consumption significantly impacts the total cost of ownership for pipe extrusion equipment. Modern, energy-efficient machines reduce power usage without sacrificing productivity, leading to substantial cost savings over time. Inquire about features such as:

- High-efficiency motors and drives

- Optimized heating and cooling systems

- Intelligent control systems that minimize waste and maximize throughput

Choosing an energy-efficient pipe extrusion equipment supplier is both environmentally responsible and financially prudent.

Delivery, Warranty, and Pricing Transparency

Clear communication regarding delivery timelines, warranty coverage, and pricing is essential. The best suppliers provide detailed quotations with no hidden fees, realistic delivery schedules, and comprehensive warranties covering critical components. Transparent business practices build trust and lay the foundation for a productive long-term partnership.

Evaluating the Supplier's Product Range

A diverse and well-developed product portfolio is a sign of a supplier's technical competence and market understanding. Leading suppliers offer:

- Single and twin-screw extruders for different material types and production requirements

- Complete extrusion lines, including upstream and downstream equipment

- Specialized solutions for multilayer or custom pipe applications

- Upgradable and modular systems for future expansion

Assess whether the supplier's product range aligns with your current and anticipated needs, and whether they can accommodate custom requests or unique challenges.

Importance of Innovation and Technology

The extrusion industry is continually evolving, with advancements in automation, process control, and material science driving improvements in quality and efficiency. Partnering with an innovative pipe extrusion equipment supplier ensures your operation remains competitive. Look for suppliers who invest in research and development, offer the latest technology, and provide regular updates or upgrades to their equipment.

Building a Long-Term Partnership

Selecting a pipe extrusion equipment supplier is not a one-time transaction-it's the beginning of an ongoing relationship. The best suppliers act as partners, offering guidance, sharing expertise, and supporting your business as it grows. Evaluate the supplier's commitment to partnership by considering:

- Responsiveness to inquiries and willingness to provide detailed information

- Willingness to customize solutions and adapt to your needs

- Proactive communication regarding maintenance, upgrades, and industry trends

- Support for process optimization and continuous improvement

A supplier who prioritizes your success will contribute far more value than one who simply delivers equipment.

Additional Considerations When Choosing a Pipe Extrusion Equipment Supplier

Technical Support and Training

A reliable pipe extrusion equipment supplier will not only deliver high-quality machinery but also ensure your team is fully trained to operate and maintain it. Look for suppliers who offer:

- Comprehensive training programs for operators and maintenance staff

- Detailed operation manuals and troubleshooting guides

- Ongoing technical support, both on-site and remotely

Proper training reduces the risk of operational errors, increases safety, and helps you get the most out of your investment.

Spare Parts Availability

Downtime due to unavailable spare parts can be costly. A reputable pipe extrusion equipment supplier will maintain a robust inventory of spare parts and consumables, ensuring rapid delivery when needed. Ask about their spare parts policy and average lead times for critical components.

Financial Stability and Business Ethics

The financial stability of your supplier is an often-overlooked but crucial factor. A financially sound pipe extrusion equipment supplier is more likely to honor warranties, invest in research and development, and provide long-term support. Additionally, choose a supplier with transparent business practices and a reputation for ethical conduct.

Global Reach and Local Presence

If your business operates internationally or plans to expand, consider a supplier with a global reach and local service capabilities. Local representatives or service centers can provide faster support, reducing downtime and ensuring smoother operations.

Conclusion

Choosing the best pipe extrusion equipment supplier is a complex decision that goes far beyond simply comparing prices. It requires a thorough evaluation of the supplier's experience, product quality, customization capabilities, after-sales support, reputation, energy efficiency, and commitment to partnership. By carefully considering these factors, you can select a supplier who not only meets your current needs but also supports your long-term growth and success. Remember, the right supplier is not just a vendor-they are a strategic partner in your manufacturing journey.

FAQ

1. What certifications should a reliable pipe extrusion equipment supplier have?

A reputable pipe extrusion equipment supplier should hold internationally recognized certifications such as ISO 9001 for quality management and CE certification for compliance with European safety standards. These certifications indicate a commitment to quality, safety, and regulatory compliance.

2. How important is after-sales support when choosing a pipe extrusion equipment supplier?

After-sales support is crucial. The best suppliers provide comprehensive technical assistance, training, spare parts availability, and preventive maintenance. Strong support minimizes downtime, extends equipment lifespan, and ensures consistent production quality.

3. Can a pipe extrusion equipment supplier customize machinery for specific production needs?

Yes, leading suppliers offer customizable solutions tailored to your material types, production volumes, pipe dimensions, and automation requirements. Customization ensures the equipment aligns perfectly with your operational goals.

4. What role does energy efficiency play in selecting a pipe extrusion equipment supplier?

Energy efficiency directly impacts operating costs and environmental sustainability. Suppliers offering energy-efficient machines with optimized motors, heating systems, and advanced controls help reduce power consumption and improve profitability.

5. How can I assess the reputation of a pipe extrusion equipment supplier?

Assess reputation by researching customer testimonials, industry reviews, and case studies. Request references, visit existing installations, and evaluate the supplier's responsiveness and transparency during the inquiry process.