Content Menu

● Introduction to Soya Food Extrusion

>> Importance of Soya Food Extrusion

● Key Factors to Consider When Choosing a Supplier

>> Top Suppliers in China

● Features of Soya Food Extrusion Equipment

>> Twin-Screw Extruders

>>> Advantages of Twin-Screw Extruders

>> Production Process

● Choosing the Right Equipment

>> Twin-Screw Extruder for Soya Chunks

● Safety and Hygiene

● Market Trends and Opportunities

>> Expanding Product Lines

● Evaluating Suppliers

>> Industry Events and Exhibitions

● Conclusion

● FAQ

>> 1. What are the key factors to consider when choosing a soya food extrusion equipment supplier?

>> 2. What types of soya food extrusion equipment are available?

>> 3. How does a twin-screw extruder work?

>> 4. What is the importance of after-sales support?

>> 5. How can I evaluate the cost-effectiveness of soya food extrusion equipment?

Choosing the right supplier for soya food extrusion equipment in China can be a daunting task, given the numerous options available. This article will guide you through the process, highlighting key factors to consider and showcasing some of the top suppliers in the industry.

Introduction to Soya Food Extrusion

Soya food extrusion is a process used to create textured soy protein products, such as soy chunks and nuggets, which are increasingly popular due to their nutritional benefits and versatility in various cuisines. The extrusion process involves subjecting soybean meal to high temperatures and pressures, transforming it into a variety of shapes and textures.

Importance of Soya Food Extrusion

- Nutritional Value: Soya products are rich in protein and can be fortified with additional nutrients, making them an excellent option for health-conscious consumers.

- Versatility: Soya chunks can be used in a wide range of dishes, from traditional Asian recipes to modern vegan and vegetarian meals.

- Sustainability: Plant-based protein sources like soy are more environmentally friendly compared to animal-derived proteins.

Key Factors to Consider When Choosing a Supplier

When selecting a supplier for soya food extrusion equipment in China, several factors should be considered:

1. Quality and Reliability: Ensure the equipment is durable and consistently produces high-quality products. Look for suppliers with a reputation for reliability and customer satisfaction.

2. Production Capacity: Choose a supplier that can meet your production needs. Consider the capacity of the machines and whether they can handle the volume you require.

3. Customization Options: Some suppliers offer customization options, which can be beneficial if you need specific features or configurations tailored to your production line.

4. After-Sales Support: Good after-sales support is crucial for troubleshooting and maintenance. Ensure the supplier provides comprehensive support and training.

5. Safety and Hygiene Standards: The equipment should meet all necessary safety and hygiene standards to ensure safe food production.

6. Cost and ROI: Evaluate the cost of the equipment against its potential return on investment. Consider both the initial purchase price and ongoing operational costs.

Top Suppliers in China

Some of the top suppliers in China include:

- Shandong Loyal Industrial Co., Ltd.: Known for their high-quality soya nuggets making machines and comprehensive customer support.

- HUAKE: Offers a wide range of extruder machines with competitive pricing and customization options.

- Shandong Forward Machinery Co., Ltd.: Specializes in twin-screw extruders for soya chunks, providing efficient and cost-effective solutions.

Features of Soya Food Extrusion Equipment

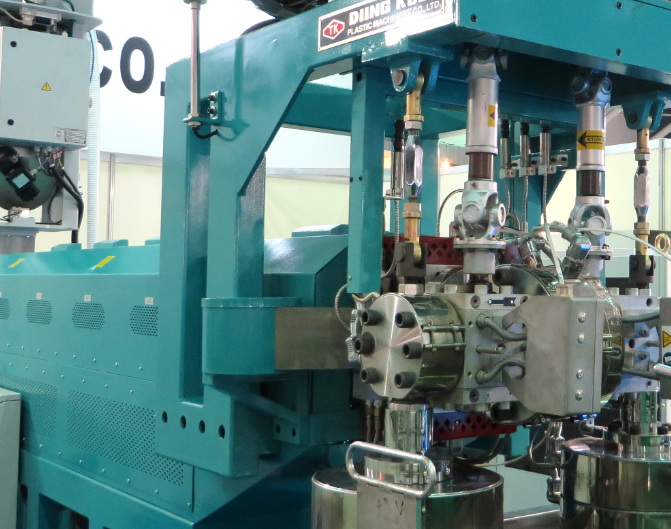

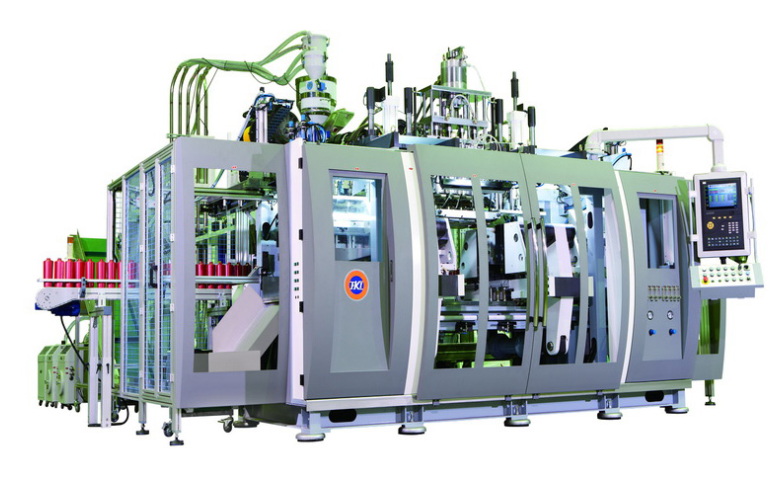

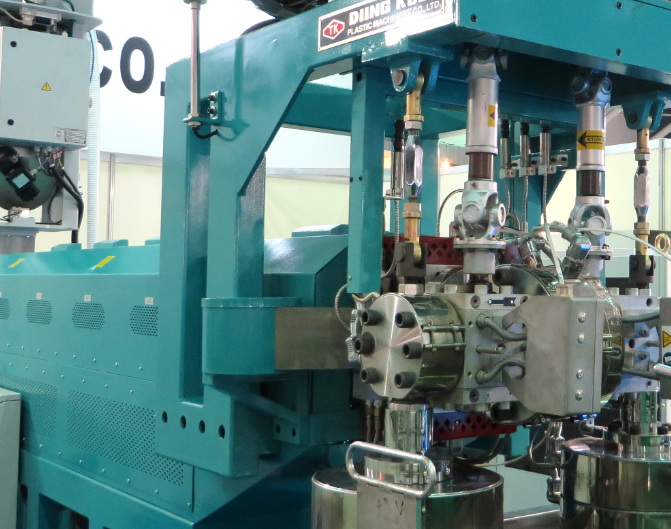

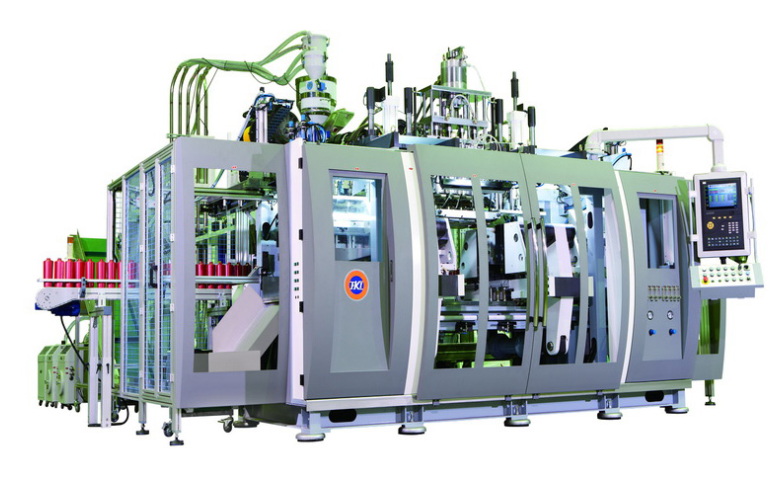

Twin-Screw Extruders

Twin-screw extruders are commonly used for soya food extrusion due to their ability to handle a wide range of raw materials and produce consistent outputs. These machines are versatile, allowing for the production of various shapes and textures by changing the die.

Advantages of Twin-Screw Extruders

- Flexibility: Can process different types of raw materials, including soybeans, peanuts, and hemp.

- Efficiency: Offers high production capacity with low energy consumption.

- Easy Maintenance: Designed for easy cleaning and maintenance, reducing downtime.

Production Process

The production process typically involves the following stages:

1. Raw Material Input: Soybeans or other raw materials are fed into the extruder.

2. Mixing and Extrusion: The raw materials are mixed and then subjected to high temperature and pressure in the extruder.

3. Shaping: The extruded material is passed through a die to create the desired shape.

4. Drying and Cooling: The shaped products are dried and cooled to remove excess moisture.

5. Packing: The final products are packaged for distribution.

Choosing the Right Equipment

When selecting soya food extrusion equipment, consider the following:

- Capacity: Ensure the machine can meet your production volume requirements.

- Product Requirements: Different products may require specialized extrusion processes or equipment.

- Quality and Durability: Look for equipment that is durable and produces consistent quality products.

- Cost and ROI: Evaluate the cost against potential returns and long-term benefits.

Twin-Screw Extruder for Soya Chunks

Twin-screw extruders are particularly popular for soya chunk production due to their ability to produce consistent textures and shapes. These machines are designed to handle high volumes efficiently, making them ideal for large-scale production.

Safety and Hygiene

Ensure the equipment meets all necessary safety and hygiene standards. Features such as easy cleaning and food-grade materials are essential for maintaining a safe production environment. Regular maintenance and cleaning protocols should be in place to prevent contamination and ensure compliance with food safety regulations.

Market Trends and Opportunities

The demand for plant-based protein products is increasing globally, driven by consumer interest in health and sustainability. This trend presents significant opportunities for businesses investing in soya food extrusion equipment. By partnering with a reliable supplier, companies can capitalize on this growing market and expand their product offerings.

Expanding Product Lines

In addition to traditional soya chunks and nuggets, companies can explore other product lines such as soy-based meat alternatives, textured soy protein for pet food, and even soy-based snack foods. This diversification can help businesses stay competitive and adapt to changing consumer preferences.

Evaluating Suppliers

When evaluating potential suppliers, consider visiting their facilities or attending industry exhibitions to see the equipment in operation. This hands-on experience can provide valuable insights into the quality and performance of the machinery.

Industry Events and Exhibitions

Industry events offer a platform to connect with suppliers, learn about new technologies, and network with other professionals in the field. These events can be invaluable for finding the right supplier and staying updated on industry trends.

Conclusion

Choosing the best China soya food extrusion equipment supplier involves careful consideration of several factors, including quality, production capacity, customization options, after-sales support, and cost. Top suppliers like Shandong Loyal Industrial Co., Ltd. and Shandong Forward Machinery Co., Ltd. offer reliable and efficient solutions for soya food extrusion. By understanding the production process and key features of soya food extrusion equipment, you can make an informed decision that meets your business needs.

FAQ

1. What are the key factors to consider when choosing a soya food extrusion equipment supplier?

When selecting a supplier, consider factors such as quality and reliability, production capacity, customization options, after-sales support, safety and hygiene standards, and cost.

2. What types of soya food extrusion equipment are available?

Commonly used equipment includes twin-screw extruders, which are versatile and efficient for producing a variety of soya products.

3. How does a twin-screw extruder work?

A twin-screw extruder subjects raw materials to high temperatures and pressures, allowing for the creation of different shapes and textures by changing the die.

4. What is the importance of after-sales support?

Good after-sales support is crucial for troubleshooting, maintenance, and ensuring the longevity of the equipment.

5. How can I evaluate the cost-effectiveness of soya food extrusion equipment?

Evaluate the cost by considering both the initial purchase price and ongoing operational costs against potential returns and long-term benefits.