Content Menu

● Understanding Aluminum Extrusion T-Nuts

● The Role of T-Nuts in Framework Strength

>> Load Distribution

>> Enhanced Stability

>> Flexibility in Design

>> Ease of Assembly

>> Corrosion Resistance

● Types of Aluminum Extrusion T-Nuts

>> Drop-In T-Nuts

>> Slide-In T-Nuts

>> Swivel T-Nuts

>> Locking T-Nuts

● Practical Applications of T-Nuts

>> Industrial Automation

>> Robotics

>> Furniture Design

>> Exhibition Stands

>> Custom Machinery

● Tips for Using Aluminum Extrusion T-Nuts

>> Choose the Right Type

>> Ensure Proper Alignment

>> Use the Correct Fasteners

>> Regular Maintenance

>> Consider Load Limits

● Conclusion

● Frequently Asked Questions

>> 1. What are the advantages of using aluminum extrusion T-nuts?

>> 2. How do I choose the right T-nut for my project?

>> 3. Can T-nuts be reused?

>> 4. What maintenance is required for T-nuts?

>> 5. Are there any limitations to using T-nuts?

Understanding Aluminum Extrusion T-Nuts

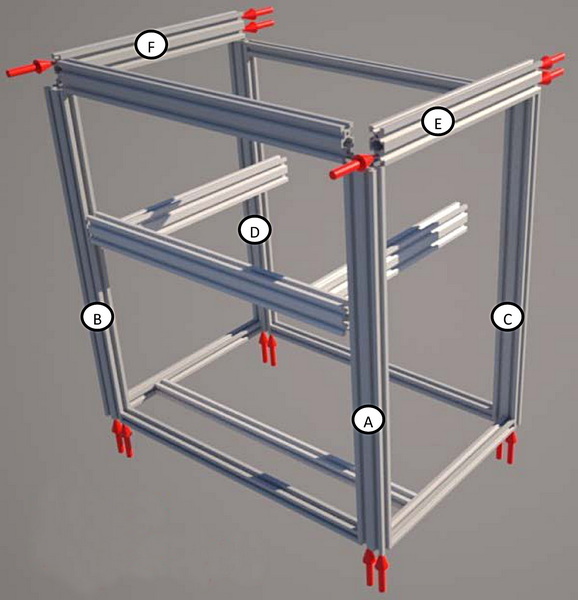

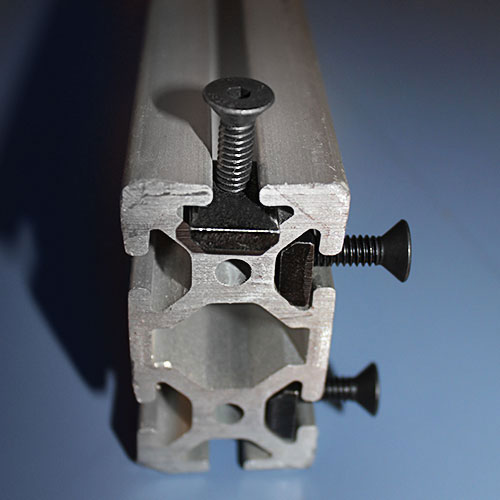

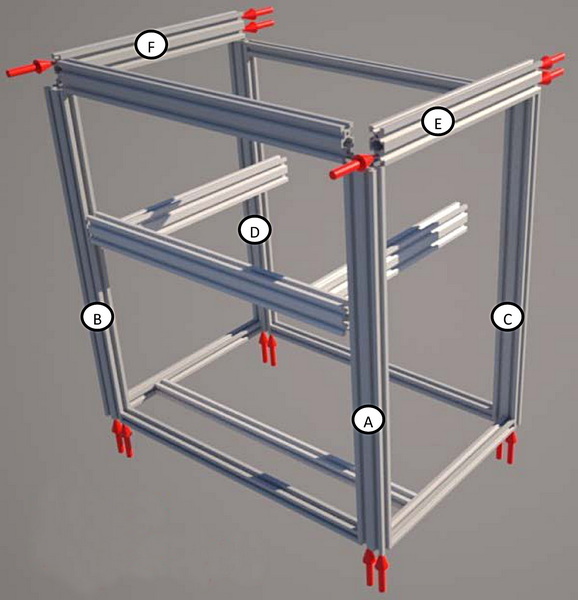

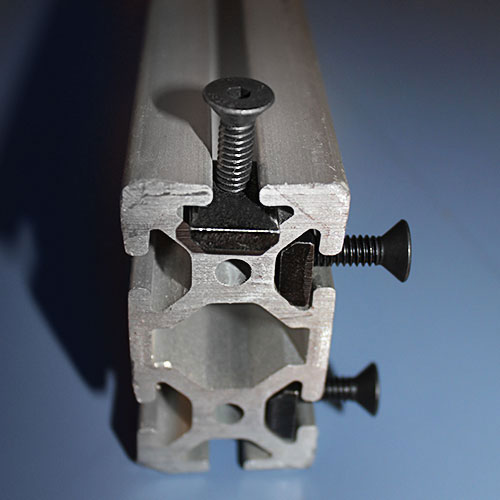

Aluminum extrusion T-nuts are essential components in the world of modular construction and assembly. They play a crucial role in enhancing the strength and stability of frameworks made from aluminum extrusions. T-nuts are specialized fasteners designed to fit into the grooves of aluminum extrusions, allowing for easy attachment of components. They provide a secure connection that can withstand significant loads, making them indispensable in various applications.

T-nuts come in various shapes and sizes, but they all share a common feature: a threaded hole that allows for the insertion of bolts or screws. This design enables T-nuts to be used in a wide range of configurations, making them versatile for different structural needs.

The Role of T-Nuts in Framework Strength

Load Distribution

One of the primary functions of T-nuts is to distribute loads evenly across the framework. When a load is applied to a structure, it can create stress points that may lead to failure. T-nuts help to spread this load across multiple points, reducing the risk of structural failure. This is particularly important in applications where heavy machinery or equipment is involved, as uneven load distribution can lead to catastrophic failures.

Enhanced Stability

T-nuts provide a stable connection between different components of the framework. This stability is crucial for maintaining the integrity of the structure, especially in applications where vibrations or dynamic loads are present. For instance, in industrial automation, where machinery operates continuously, the stability provided by T-nuts ensures that the framework remains intact and functional over time.

Flexibility in Design

The use of T-nuts allows for greater flexibility in design. They enable quick adjustments and modifications to the framework without compromising its strength. This adaptability is particularly beneficial in industries where designs may need to change frequently, such as in robotics or custom furniture design. With T-nuts, engineers and designers can easily reconfigure their structures to meet new requirements or specifications.

Ease of Assembly

T-nuts simplify the assembly process. They can be easily inserted into the grooves of aluminum extrusions, allowing for quick and efficient construction. This ease of use can significantly reduce assembly time and labor costs. In many cases, the use of T-nuts can cut assembly time in half compared to traditional fastening methods, making them a preferred choice in fast-paced manufacturing environments.

Corrosion Resistance

Most aluminum extrusion T-nuts are made from materials that resist corrosion, ensuring that the connections remain strong over time. This durability is essential for frameworks exposed to harsh environments, such as outdoor installations or industrial settings where moisture and chemicals are present. The corrosion resistance of T-nuts contributes to the longevity of the entire structure, reducing maintenance costs and downtime.

Types of Aluminum Extrusion T-Nuts

There are several types of T-nuts available, each designed for specific applications:

Drop-In T-Nuts

These are designed to be dropped into the extrusion groove from the end. They are ideal for applications where the end of the extrusion is accessible. Drop-in T-nuts are commonly used in situations where quick assembly and disassembly are required.

Slide-In T-Nuts

These T-nuts can be slid into the groove from the side, making them suitable for applications where the end is not accessible. Slide-in T-nuts are particularly useful in tight spaces or when working with pre-assembled structures.

Swivel T-Nuts

These T-nuts can rotate within the groove, allowing for greater flexibility in positioning components. Swivel T-nuts are beneficial in applications where adjustments may be needed after initial assembly, such as in adjustable shelving systems.

Locking T-Nuts

These T-nuts feature a locking mechanism that prevents them from loosening over time, making them ideal for high-vibration applications. Locking T-nuts are commonly used in automotive and aerospace applications, where safety and reliability are paramount.

Practical Applications of T-Nuts

Aluminum extrusion T-nuts are used in a wide range of applications, including:

Industrial Automation

In manufacturing environments, T-nuts are used to create custom workstations, conveyor systems, and machine frames. Their ability to provide strong, adjustable connections makes them ideal for the dynamic needs of industrial automation.

Robotics

T-nuts are commonly used in robotic applications to build lightweight and strong structures that can withstand dynamic loads. The modular nature of aluminum extrusions combined with T-nuts allows for rapid prototyping and design iterations in robotics.

Furniture Design

Many modern furniture designs utilize aluminum extrusions and T-nuts for their strength and aesthetic appeal. Designers appreciate the clean lines and versatility of aluminum, and T-nuts allow for easy customization of furniture pieces.

Exhibition Stands

T-nuts are used to create modular exhibition stands that can be easily assembled and disassembled. This flexibility is crucial for trade shows and exhibitions, where quick setup and takedown are essential.

Custom Machinery

In custom machinery applications, T-nuts provide the necessary strength and adjustability to accommodate various components. This is particularly important in industries where machinery must be tailored to specific tasks or products.

Tips for Using Aluminum Extrusion T-Nuts

Choose the Right Type

Select the appropriate type of T-nut based on your application. Consider factors such as load requirements, accessibility, and the need for adjustability. Understanding the specific needs of your project will help you choose the most effective T-nut.

Ensure Proper Alignment

When inserting T-nuts, ensure they are properly aligned with the groove to avoid cross-threading and ensure a secure fit. Misalignment can lead to weak connections and potential structural failures.

Use the Correct Fasteners

Pair T-nuts with the right bolts or screws to ensure a strong connection. The diameter and length of the fastener should match the specifications of the T-nut. Using mismatched fasteners can compromise the integrity of the connection.

Regular Maintenance

Periodically check the connections for signs of wear or loosening. Tighten any loose fasteners to maintain the integrity of the framework. Regular maintenance is key to ensuring the longevity and reliability of your structure.

Consider Load Limits

Be aware of the load limits of both the T-nuts and the aluminum extrusions. Exceeding these limits can compromise the strength of the framework. Always adhere to manufacturer specifications to ensure safe and effective use.

Conclusion

Aluminum extrusion T-nuts are vital components that significantly enhance the strength and stability of frameworks. Their ability to distribute loads, provide stability, and allow for flexible design makes them an excellent choice for various applications. By understanding the different types of T-nuts and how to use them effectively, you can create robust and reliable structures that meet your specific needs.

Frequently Asked Questions

1. What are the advantages of using aluminum extrusion T-nuts?

Aluminum extrusion T-nuts offer load distribution, enhanced stability, design flexibility, ease of assembly, and corrosion resistance. These advantages make them ideal for a wide range of applications.

2. How do I choose the right T-nut for my project?

Consider the application requirements, load limits, and accessibility when selecting the appropriate type of T-nut. Understanding your project's specific needs will guide you in making the best choice.

3. Can T-nuts be reused?

Yes, T-nuts can be reused as long as they are not damaged and the associated fasteners are still in good condition. Reusing T-nuts can be a cost-effective solution in modular designs.

4. What maintenance is required for T-nuts?

Regularly check for loose connections and tighten any fasteners as needed to maintain the integrity of the framework. Periodic inspections will help ensure the long-term performance of your structure.

5. Are there any limitations to using T-nuts?

T-nuts have load limits, and exceeding these limits can compromise the strength of the framework. Always adhere to manufacturer specifications to ensure safe and effective use.