Content Menu

● The Importance of Aluminum Extrusion Profile Accessories

● Types of Aluminum Extrusion Profile Accessories

>> 1. Connectors and Fasteners

>> 2. End Caps and Cover Strips

>> 3. Wheels and Casters

>> 4. Handles and Hinges

>> 5. Inserts

● How Aluminum Extrusion Profile Accessories Enhance Structural Integrity

>> Reinforcement and Strength

>> Load Distribution

>> Efficient Assembly and Customization

>> Corrosion Resistance

>> Weight Reduction

● Applications of Aluminum Extrusion Profile Accessories

>> 1. Construction Industry

>> 2. Automotive Sector

>> 3. Aerospace Engineering

>> 4. Industrial Equipment and Machinery

>> 5. Furniture and Display Systems

● The Manufacturing Process of Aluminum Extrusion Profile Accessories

● Benefits of Using Aluminum Extrusion Profile Accessories

● Future Trends in Aluminum Extrusion Profile Accessories

● Conclusion

● FAQs

>> 1. What are the most common types of aluminum extrusion profile accessories?

>> 2. How do aluminum extrusion profile accessories improve structural integrity?

>> 3. What industries benefit most from using aluminum extrusion profile accessories?

>> 4. Are aluminum extrusion profile accessories customizable?

>> 5. How are aluminum extrusion profile accessories typically manufactured?

● Citations:

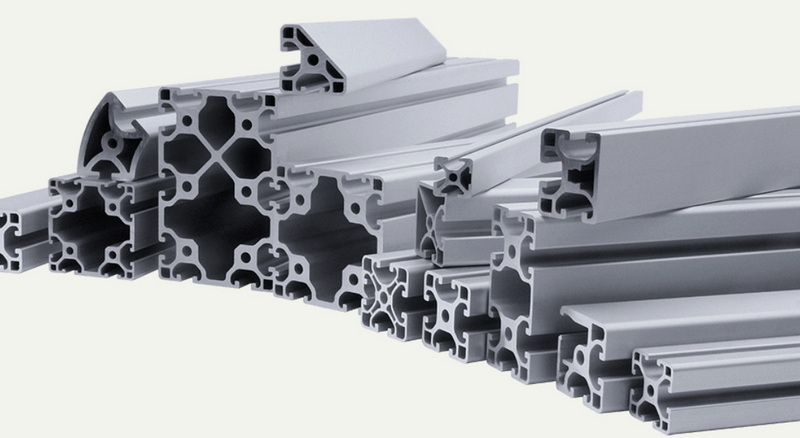

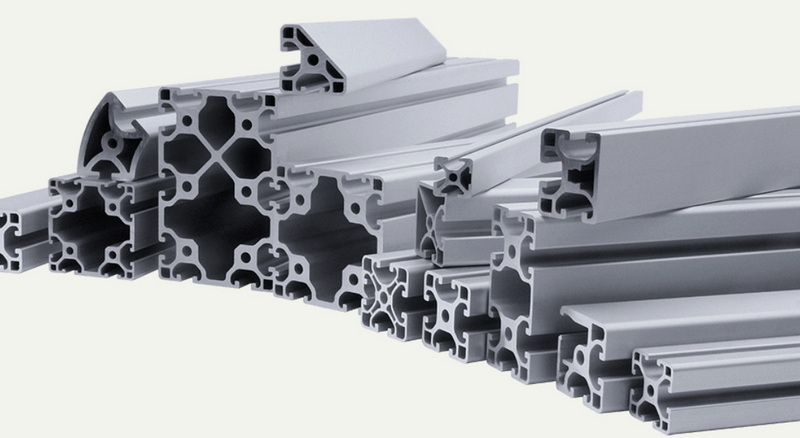

Aluminum extrusion profile accessories play a crucial role in enhancing the structural integrity of various applications across multiple industries. These components are essential for assembling, reinforcing, and customizing aluminum profile frames, providing strength, flexibility, and functionality to the overall structure. In this comprehensive article, we will explore how aluminum extrusion profile accessories contribute to improved structural integrity and examine their various applications, features, and benefits.

The Importance of Aluminum Extrusion Profile Accessories

Aluminum extrusion profile accessories are integral components that complement aluminum profiles, enabling designers and engineers to create robust and versatile structures. These accessories serve multiple purposes, including:

1. Reinforcing weak points in designs

2. Distributing loads evenly across structures

3. Facilitating efficient assembly processes

4. Enhancing the aesthetic appeal of aluminum frames

5. Providing protection and sealing functions

By incorporating these accessories, manufacturers can significantly improve the overall strength, stability, and functionality of aluminum profile structures[1][2].

Types of Aluminum Extrusion Profile Accessories

There is a wide range of aluminum extrusion profile accessories available, each designed to serve specific functions within the assembly. Some of the most common types include:

1. Connectors and Fasteners

Connectors and fasteners are essential for joining aluminum profiles and creating sturdy frameworks. These include:

- T-Nuts and Bolts

- Brackets

- Joints (End Connectors, Free Plate Connectors, Active Joint Hinges)

- Multifunctional Block Accessories

2. End Caps and Cover Strips

These accessories serve both functional and aesthetic purposes:

- End caps protect the open ends of profiles

- Cover strips enhance the visual appeal and provide sealing functions

3. Wheels and Casters

For mobile structures and equipment, wheels and casters are crucial accessories that facilitate movement and flexibility.

4. Handles and Hinges

These components are essential for doors, drawers, and other movable parts within aluminum profile structures.

5. Inserts

Inserts play a vital role in reinforcing aluminum profiles and creating connection points for additional components.

How Aluminum Extrusion Profile Accessories Enhance Structural Integrity

Aluminum extrusion profile accessories contribute to structural integrity in several ways:

Reinforcement and Strength

Inserts and connectors provide additional strength to aluminum profiles, allowing designers to create lighter structures without compromising durability. By reinforcing key areas within an extruded profile, these accessories improve the overall strength and stability of the structure[2].

Load Distribution

Accessories help distribute loads more evenly across the structure, reducing stress concentrations that could lead to failure. This even distribution of forces is crucial for maintaining the integrity of the entire assembly, especially in applications subjected to dynamic loads or vibrations[2].

Efficient Assembly and Customization

Aluminum extrusion profile accessories simplify assembly processes by providing pre-defined connection points. This feature allows for quicker assembly times and reduces labor costs associated with complex joinery techniques. Additionally, the ability to customize inserts and connectors enables designers to tailor solutions for specific applications, opening up new possibilities in design[2].

Corrosion Resistance

When combined with aluminum profiles, which naturally form a protective oxide layer, accessories made from similar materials enhance the overall corrosion resistance of the assembly. This increased protection is particularly beneficial in harsh environments or outdoor applications[2].

Weight Reduction

By strategically placing inserts and using lightweight accessories, manufacturers can reduce the overall weight of structures while maintaining strength. This weight reduction is crucial in industries like aerospace and automotive, where every ounce counts[2].

Applications of Aluminum Extrusion Profile Accessories

Aluminum extrusion profile accessories find applications across various industries due to their ability to enhance structural integrity:

1. Construction Industry

In construction, these accessories are used for:

- Creating modular building systems

- Assembling curtain walls and facades

- Constructing lightweight yet sturdy scaffolding

2. Automotive Sector

The automotive industry utilizes aluminum extrusion profile accessories for:

- Designing lightweight vehicle frames

- Creating robust interior structures

- Developing energy-absorbing crash components

3. Aerospace Engineering

In aerospace applications, these accessories contribute to:

- Constructing aircraft interiors

- Building satellite structures

- Designing lightweight yet strong components for space vehicles

4. Industrial Equipment and Machinery

For industrial applications, aluminum extrusion profile accessories are used in:

- Assembling conveyor systems

- Creating workstations and assembly lines

- Building safety enclosures for machinery

5. Furniture and Display Systems

In the furniture and retail sectors, these accessories enable:

- Designing modular furniture systems

- Creating versatile display stands and showcases

- Constructing adjustable shelving units

The Manufacturing Process of Aluminum Extrusion Profile Accessories

Understanding the manufacturing process of aluminum extrusion profile accessories provides insight into their quality and performance:

1. Design Phase: Engineers assess structural requirements and determine optimal accessory placement.

2. Material Selection: Suitable materials are chosen based on strength requirements and environmental conditions.

3. Manufacturing: During the extrusion process, profiles are created with spaces or channels for accessories.

4. Assembly: Accessories are installed at designated points using mechanical fasteners or adhesives.

5. Testing and Quality Control: Finished assemblies undergo rigorous testing to ensure safety and performance standards are met.

6. Final Adjustments: Based on testing results, necessary adjustments are made to optimize performance before full-scale production begins[2].

Benefits of Using Aluminum Extrusion Profile Accessories

The incorporation of aluminum extrusion profile accessories offers numerous advantages:

1. Increased Structural Strength: Accessories reinforce weak points and improve overall stability.

2. Flexibility in Design: Customizable accessories allow for versatile and adaptable structures.

3. Ease of Assembly: Pre-defined connection points simplify the assembly process.

4. Weight Reduction: Strategic use of accessories enables lighter yet strong structures.

5. Corrosion Resistance: Properly selected accessories enhance the overall durability of the assembly.

6. Cost-Effectiveness: Simplified assembly and reduced material usage lead to cost savings.

7. Aesthetic Appeal: Accessories can improve the visual appearance of aluminum structures.

Future Trends in Aluminum Extrusion Profile Accessories

As technology advances, we can expect to see several trends in the development of aluminum extrusion profile accessories:

1. Smart Accessories: Integration of sensors and IoT capabilities for real-time monitoring of structural integrity.

2. Advanced Materials: Development of even lighter and stronger materials for accessory production.

3. Sustainable Solutions: Increased focus on eco-friendly manufacturing processes and recyclable materials.

4. 3D Printing: Adoption of additive manufacturing techniques for custom accessory production.

5. Modular Systems: Further advancement in modular design principles for even greater flexibility.

Conclusion

Aluminum extrusion profile accessories play a vital role in enhancing the structural integrity of various applications across multiple industries. By providing reinforcement, facilitating efficient assembly, and enabling customization, these accessories contribute significantly to the strength, durability, and versatility of aluminum profile structures. As technology continues to advance, we can expect even more innovative solutions in the realm of aluminum extrusion profile accessories, further expanding their capabilities and applications.

FAQs

1. What are the most common types of aluminum extrusion profile accessories?

The most common types include connectors (such as T-nuts, bolts, and brackets), end caps, cover strips, wheels, casters, handles, hinges, and inserts. Each type serves specific functions in assembling and enhancing aluminum profile structures[1][4].

2. How do aluminum extrusion profile accessories improve structural integrity?

Aluminum extrusion profile accessories improve structural integrity by reinforcing weak points, distributing loads evenly, facilitating efficient assembly, and allowing for customization. They enhance overall strength, stability, and functionality of aluminum profile structures[2].

3. What industries benefit most from using aluminum extrusion profile accessories?

Industries that benefit significantly include construction, automotive, aerospace, industrial equipment manufacturing, and furniture design. These sectors leverage the strength, lightweight properties, and versatility offered by aluminum extrusion profile accessories[2][5].

4. Are aluminum extrusion profile accessories customizable?

Yes, many aluminum extrusion profile accessories can be customized to meet specific design requirements. This customization allows for tailored solutions based on application needs and load-bearing demands[2][5].

5. How are aluminum extrusion profile accessories typically manufactured?

Aluminum extrusion profile accessories are primarily manufactured through extrusion processes. The process involves forcing heated aluminum through a die with the desired shape and size of the specific accessory. After extrusion, the accessories are cooled and aged to enhance strength[5].

Citations:

[1] https://jlcmc.com/blog/Analysis-of-aluminum-extrusion-accessories-from-3-aspects

[2] https://www.yjing-extrusion.com/how-do-aluminum-extrusion-inserts-improve-structural-integrity.html

[3] https://www.industrialprofile.com/important-aluminum-extrusion-profile-accessories/

[4] https://haluminium.com/Products/aluminium-extrusion-profile-accessories/

[5] https://www.wellste.com/aluminium-profile-accessories/

[6] https://technical.europe.misumi-ec.com/en/support/solutions/articles/76000046645-aluminum-extrusions-general-questions

[7] https://starext.com/news/aluminum-extrusion-finishing-fabrication-frequently-asked-questions-faq