Content Menu

● Understanding Heat Sinks

>> Types of Heat Sinks

● Aluminum Extrusion Heat Sinks

● Comparing Aluminum Extrusion Heat Sinks to Other Cooling Solutions

>> Thermal Performance

>> Cost

>> Weight

>> Ease of Installation

● Applications of Aluminum Extrusion Heat Sinks

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary advantage of aluminum extrusion heat sinks?

>> 2. How do aluminum heat sinks compare to copper heat sinks?

>> 3. Can aluminum extrusion heat sinks be customized?

>> 4. What are the common applications for aluminum extrusion heat sinks?

>> 5. Are active cooling solutions more effective than aluminum heat sinks?

Understanding Heat Sinks

Heat sinks are passive cooling devices designed to dissipate heat generated by electronic components. They work by increasing the surface area available for heat dissipation, allowing heat to be transferred away from the component and into the surrounding air. The effectiveness of a heat sink depends on several factors, including its material, design, and the airflow around it.

Types of Heat Sinks

There are several types of heat sinks, each with its own advantages and disadvantages:

- Passive Heat Sinks: These rely solely on natural convection to dissipate heat. They are typically made from materials with high thermal conductivity, such as aluminum or copper. Passive heat sinks are often used in applications where noise is a concern, as they do not have moving parts.

- Active Heat Sinks: These incorporate fans or other mechanical means to enhance airflow and improve heat dissipation. While they can be more effective than passive heat sinks, they also introduce moving parts that can fail over time. Active heat sinks are commonly found in high-performance computing applications where heat generation is significant.

- Heat Pipes: These are sealed tubes containing a liquid that evaporates and condenses to transfer heat. Heat pipes can be integrated into heat sinks to improve their performance. They are particularly effective in applications where space is limited, as they can transfer heat over longer distances without requiring large heat sinks.

- Liquid Cooling Systems: These systems use a liquid coolant to absorb heat from components and transfer it to a radiator, where it is dissipated into the air. Liquid cooling is often used in high-performance applications, such as gaming PCs and servers, where traditional air cooling may not suffice.

Aluminum Extrusion Heat Sinks

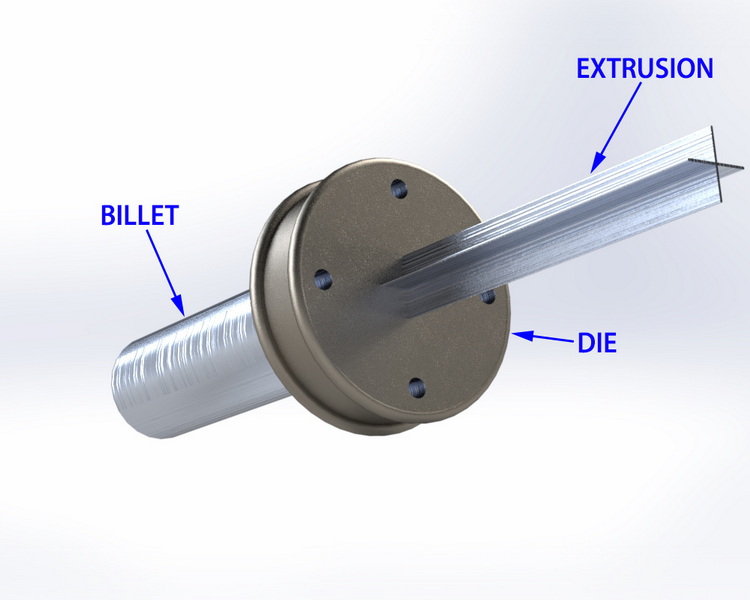

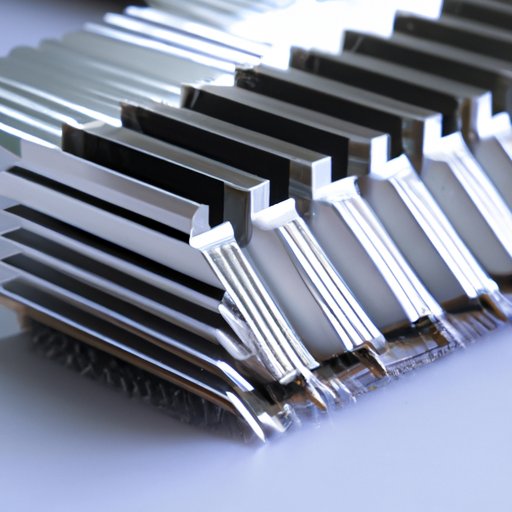

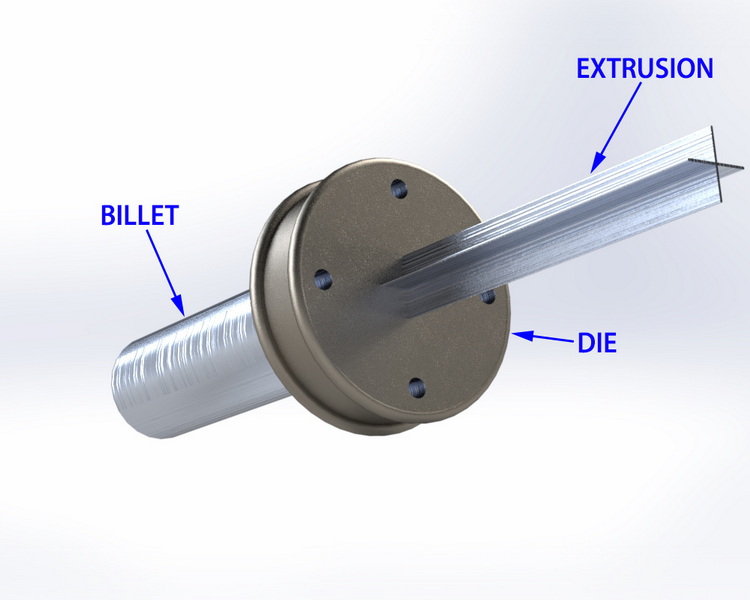

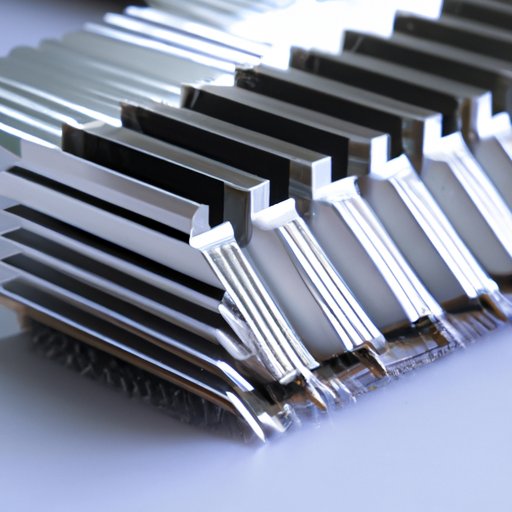

Aluminum extrusion heat sinks are made by forcing aluminum through a die to create a specific shape. This manufacturing process allows for the creation of complex geometries that maximize surface area and improve thermal performance. Here are some key benefits of aluminum extrusion heat sinks:

- High Thermal Conductivity: Aluminum has excellent thermal conductivity, which allows it to efficiently transfer heat away from components. This property is crucial in preventing overheating and ensuring the longevity of electronic devices.

- Lightweight: Compared to copper, aluminum is significantly lighter, making it an ideal choice for applications where weight is a concern. This is particularly important in portable devices, such as laptops and smartphones, where every gram counts.

- Cost-Effective: Aluminum is generally less expensive than copper, making aluminum extrusion heat sinks a cost-effective solution for many applications. This affordability allows manufacturers to keep production costs low while maintaining quality.

- Versatile Design: The extrusion process allows for a wide range of shapes and sizes, enabling designers to create heat sinks that fit specific applications. This versatility is beneficial in industries where space constraints are common.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion and suitable for various environments. This property is particularly advantageous in outdoor applications or environments with high humidity.

Comparing Aluminum Extrusion Heat Sinks to Other Cooling Solutions

When comparing aluminum extrusion heat sinks to other cooling solutions, several factors come into play, including thermal performance, cost, weight, and ease of installation.

Thermal Performance

Thermal performance is one of the most critical factors when evaluating heat sinks. Aluminum extrusion heat sinks offer excellent thermal conductivity, which allows them to dissipate heat effectively. However, their performance can be influenced by design features such as fin density, height, and overall surface area.

In contrast, active cooling solutions, such as fans and liquid cooling systems, can provide superior thermal performance in high-demand applications. For example, a well-designed liquid cooling system can maintain lower temperatures than a passive aluminum heat sink, especially in overclocked or high-performance scenarios. The ability to control the temperature more precisely can lead to better performance and reliability in demanding environments.

Cost

Cost is another essential consideration. Aluminum extrusion heat sinks are generally more affordable than copper heat sinks and other active cooling solutions. This cost-effectiveness makes them an attractive option for manufacturers looking to balance performance and budget.

Active cooling solutions, while often more effective, can be more expensive due to the additional components required, such as pumps, radiators, and fans. Additionally, the installation and maintenance costs for these systems can be higher than for passive aluminum heat sinks. Manufacturers must weigh the initial investment against the long-term benefits of improved cooling performance.

Weight

Weight is a crucial factor in applications where portability is essential, such as laptops and mobile devices. Aluminum extrusion heat sinks are significantly lighter than copper heat sinks, making them a preferred choice for lightweight designs. In contrast, active cooling solutions can add considerable weight due to the additional components involved. This added weight can be a disadvantage in portable applications, where users prioritize lightweight designs.

Ease of Installation

Aluminum extrusion heat sinks are relatively easy to install, requiring minimal additional components. They can be directly attached to components using thermal adhesive or screws, making them a straightforward solution for many applications. This ease of installation can lead to reduced assembly times and lower labor costs.

Active cooling solutions, on the other hand, can be more complex to install. Liquid cooling systems, for example, require careful assembly and may involve routing tubes and securing pumps, which can be time-consuming and require more technical expertise. The complexity of installation can deter some users from opting for these systems, especially in consumer electronics.

Applications of Aluminum Extrusion Heat Sinks

Aluminum extrusion heat sinks are widely used in various applications, including:

- Consumer Electronics: Laptops, smartphones, and tablets often utilize aluminum heat sinks to manage heat generated by processors and graphics chips. The compact design of aluminum heat sinks allows them to fit into tight spaces while providing effective cooling.

- LED Lighting: Aluminum heat sinks are commonly used in LED lighting fixtures to dissipate heat and prolong the lifespan of the LEDs. Effective thermal management is crucial in LED applications, as excessive heat can lead to reduced efficiency and shorter lifespans.

- Automotive: In electric vehicles and hybrid cars, aluminum heat sinks are used to manage heat in battery packs and power electronics. As the automotive industry shifts towards electrification, effective thermal management solutions are becoming increasingly important.

- Industrial Equipment: Many industrial machines and equipment rely on aluminum heat sinks to maintain optimal operating temperatures. In environments where equipment operates continuously, effective cooling solutions are essential to prevent overheating and ensure reliability.

- Telecommunications: In telecommunications equipment, aluminum heat sinks are used to dissipate heat generated by high-power amplifiers and other components. The reliability of these systems is critical, as they support essential communication infrastructure.

Conclusion

In summary, aluminum extrusion heat sinks offer a range of benefits, including high thermal conductivity, lightweight design, cost-effectiveness, and versatility. While they may not always match the thermal performance of active cooling solutions, they provide an excellent balance of performance and affordability for many applications. As technology continues to evolve, aluminum extrusion heat sinks will remain a popular choice for thermal management in various industries.

Frequently Asked Questions

1. What is the primary advantage of aluminum extrusion heat sinks?

The primary advantage is their excellent thermal conductivity combined with a lightweight and cost-effective design, making them suitable for a wide range of applications.

2. How do aluminum heat sinks compare to copper heat sinks?

Aluminum heat sinks are lighter and less expensive than copper heat sinks, but copper has better thermal conductivity, making it more effective in certain high-performance applications.

3. Can aluminum extrusion heat sinks be customized?

Yes, the extrusion process allows for a wide range of shapes and sizes, making customization possible for specific applications, which is beneficial in industries with unique design requirements.

4. What are the common applications for aluminum extrusion heat sinks?

They are commonly used in consumer electronics, LED lighting, automotive applications, industrial equipment, and telecommunications, where effective thermal management is essential.

5. Are active cooling solutions more effective than aluminum heat sinks?

Active cooling solutions can provide superior thermal performance in high-demand applications, but they are often more complex and expensive, requiring careful consideration of the specific needs of the application.

This comprehensive exploration of aluminum extrusion heat sinks and their comparison to other cooling solutions highlights their importance in modern thermal management. As technology advances, the demand for efficient and effective cooling solutions will continue to grow, ensuring that aluminum extrusion heat sinks remain a vital component in various industries.