Content Menu

● Understanding Aluminum Extrusion

>> Key Benefits of Aluminum Extrusion Framing Systems

● Enhancing Structural Integrity with Aluminum Extrusion Framing Systems

>> 1. Design Flexibility

>> 2. Connection Strength

>> 3. Vibration Damping

>> 4. Resistance to Environmental Factors

● Applications of Aluminum Extrusion Framing Systems

● Innovations in Aluminum Extrusion Technology

● Visual Representation

● Conclusion

● FAQ

>> 1. What are aluminum extrusion framing systems?

>> 2. How do aluminum extrusions compare to steel?

>> 3. Can aluminum extrusion frames be customized?

>> 4. What maintenance is required for aluminum frames?

>> 5. Are aluminum extrusion framing systems environmentally friendly?

● Citations:

Aluminum extrusion framing systems have revolutionized the construction and manufacturing industries by providing a robust, versatile, and efficient solution for building structural frameworks. These systems utilize aluminum extrusions, which are lightweight yet strong, making them ideal for a wide range of applications. This article explores how aluminum extrusion framing systems enhance structural integrity, their benefits over traditional materials, and their various applications.

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into specific cross-sectional profiles by forcing it through a die. This method allows for the creation of complex shapes with high precision, which can be tailored to meet specific design requirements. The most common profiles used in framing systems are T-slot extrusions, which feature grooves that enable easy assembly and disassembly.

Key Benefits of Aluminum Extrusion Framing Systems

- Lightweight and Strong: Aluminum has a high strength-to-weight ratio, making it lighter than steel while still providing comparable strength. This property allows for easier handling and installation of framing components.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that prevents rust and corrosion. This characteristic ensures that aluminum frames maintain their structural integrity over time, even in harsh environments.

- Modularity: The T-slot design of aluminum extrusions allows for modular construction. Components can be easily added, removed, or reconfigured without the need for specialized tools or welding.

- Ease of Assembly: Unlike traditional welded structures that require skilled labor and extensive setup time, aluminum extrusion framing systems can be assembled quickly using simple hand tools. This reduces labor costs and minimizes downtime during installation.

- Customization: Aluminum extrusions can be manufactured in various shapes and sizes to meet specific project needs. This flexibility makes them suitable for a wide range of applications, from industrial machinery to architectural designs.

Enhancing Structural Integrity with Aluminum Extrusion Framing Systems

The structural integrity of a framework is crucial for its performance and longevity. Aluminum extrusion framing systems improve structural integrity through several mechanisms:

1. Design Flexibility

Aluminum extrusions can be designed to distribute loads effectively across the structure. By optimizing the cross-sectional shape and size of the extrusions, engineers can create frames that can withstand significant forces without failure. For example, an I-beam shape may be used in areas where heavy loads are anticipated, while lighter profiles can be employed in less critical sections.

2. Connection Strength

The T-slot design allows for secure connections between components using specialized fasteners. These connections can mimic the strength of welded joints while providing the added benefit of being adjustable. If a part becomes damaged or needs to be replaced, it can be swapped out easily without compromising the entire structure. This modularity not only enhances structural integrity but also simplifies repairs and upgrades.

3. Vibration Damping

Aluminum has inherent damping properties that help absorb vibrations. This characteristic is particularly beneficial in applications involving machinery or equipment that generates significant vibrations during operation. By reducing vibration transmission through the frame, aluminum extrusions help maintain structural integrity and prolong the lifespan of connected components.

4. Resistance to Environmental Factors

Aluminum's resistance to corrosion makes it an ideal choice for outdoor applications or environments exposed to moisture and chemicals. Unlike steel frames that may deteriorate over time due to rust, aluminum maintains its strength and appearance, ensuring long-term reliability. Furthermore, anodizing processes can enhance this resistance by adding an extra layer of protection against environmental stressors.

Applications of Aluminum Extrusion Framing Systems

Aluminum extrusion framing systems are used in various industries due to their versatility and strength:

- Industrial Automation: Many factories use aluminum framing systems to build machine bases, safety enclosures, and workstations that require precise alignment and stability. The ability to create custom setups tailored to specific machinery enhances operational efficiency.

- Architectural Structures: In construction, aluminum extrusions are used for window frames, curtain walls, and other architectural elements where aesthetics and performance are essential. Their sleek appearance complements modern designs while providing excellent thermal insulation properties when combined with appropriate glazing techniques.

- Transportation: Lightweight aluminum frames are increasingly used in vehicles and aircraft to reduce weight while maintaining structural integrity. In aviation applications, every ounce counts; thus, using aluminum helps improve fuel efficiency without sacrificing safety.

- Furniture Design: Modular furniture made from aluminum extrusions allows for customizable office layouts that can adapt to changing needs. Desks, shelving units, and partitions can be easily reconfigured as workspace requirements evolve.

Innovations in Aluminum Extrusion Technology

Recent advancements in aluminum extrusion technology have further enhanced the capabilities of these framing systems:

- Advanced Alloys: New aluminum alloys with improved mechanical properties have been developed to meet specific performance requirements in demanding applications. These alloys offer higher strength while maintaining lightweight characteristics.

- 3D Printing Integration: The integration of 3D printing with aluminum extrusion allows for rapid prototyping of complex designs that can then be manufactured at scale using traditional extrusion methods. This synergy accelerates product development cycles across various industries.

- Sustainable Practices: The growing emphasis on sustainability has led to innovations in recycling processes for aluminum scrap generated during manufacturing. Closed-loop recycling systems ensure that waste materials are repurposed effectively, reducing environmental impact.

Visual Representation

To illustrate the advantages of aluminum extrusion framing systems further, consider the following images:

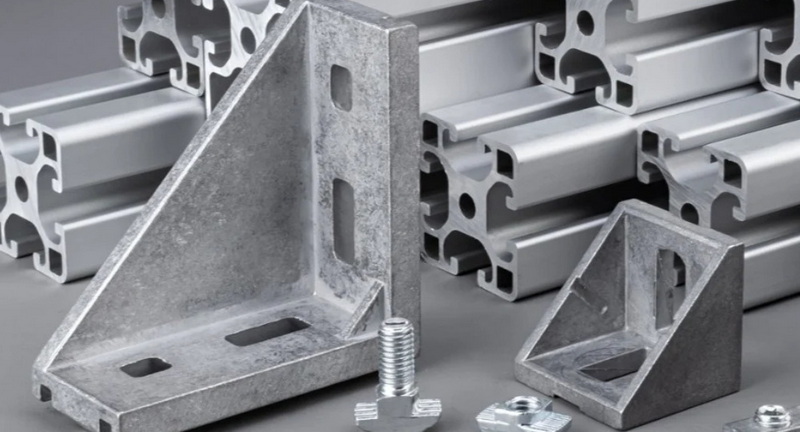

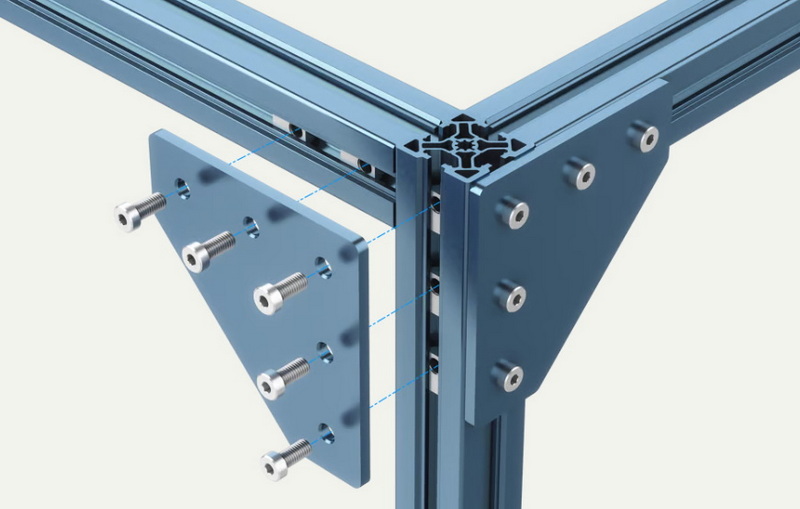

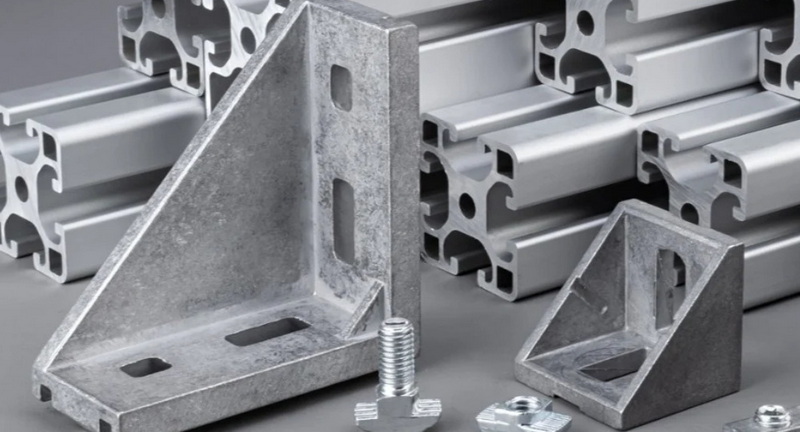

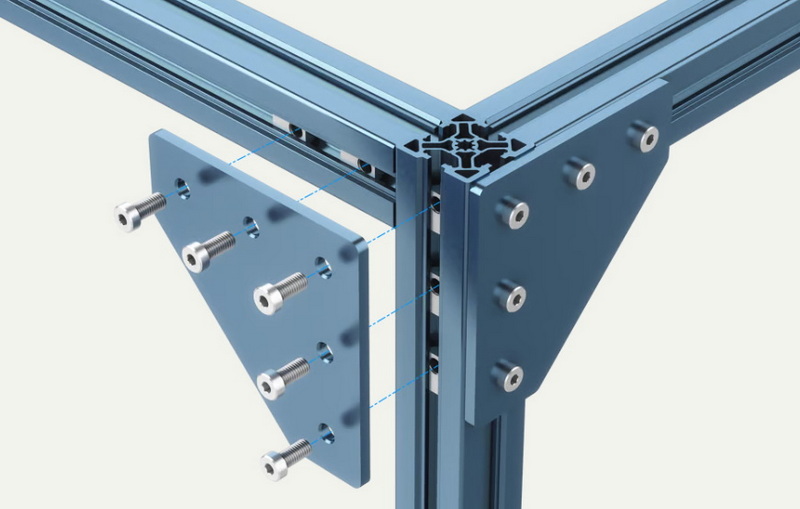

1. T-Slot Aluminum Extrusion Assembly

T-Slot Assembly

*A visual representation of a T-slot assembly showcasing its modularity.*

2. Industrial Automation Setup

Industrial Setup

*An example of an industrial automation setup utilizing aluminum framing.*

3. Architectural Applications

Architectural Use

*Aluminum extrusions used in architectural designs demonstrating aesthetic appeal.*

4. Transportation Applications

Transportation Use

*Lightweight aluminum frames used in vehicle manufacturing.*

5. Furniture Design Examples

Furniture Design

*Modular furniture solutions utilizing aluminum extrusion.*

Conclusion

Aluminum extrusion framing systems significantly enhance structural integrity through their lightweight design, corrosion resistance, modularity, ease of assembly, and customization options. These benefits make them an ideal choice across various industries—from industrial automation to architecture—where strength and adaptability are paramount.

As industries continue to evolve towards more efficient manufacturing processes and sustainable materials, aluminum extrusion framing systems will undoubtedly play a crucial role in shaping the future of structural engineering.

FAQ

1. What are aluminum extrusion framing systems?

Aluminum extrusion framing systems consist of profiles created by forcing aluminum through a die to form specific shapes like T-slots. These profiles are used to construct modular frameworks for various applications.

2. How do aluminum extrusions compare to steel?

While steel is generally stronger than aluminum on a pound-for-pound basis, aluminum offers significant advantages in terms of weight reduction, corrosion resistance, ease of assembly, and flexibility in design.

3. Can aluminum extrusion frames be customized?

Yes! Aluminum extrusions can be manufactured in various shapes and sizes tailored to specific project requirements, allowing for high levels of customization in design.

4. What maintenance is required for aluminum frames?

Aluminum frames require minimal maintenance due to their corrosion-resistant properties. Regular cleaning is typically sufficient to maintain their appearance and functionality.

5. Are aluminum extrusion framing systems environmentally friendly?

Yes! Aluminum is highly recyclable without losing its structural integrity. Using aluminum reduces reliance on less sustainable materials like steel while promoting eco-friendly practices in construction.

Citations:

[1] https://jieyatwinscrew.com/blog/80-20-aluminum-extrusion/

[2] https://anglelock.com/blog/metal-framing-systems-welded-steel-aluminum-extrusion

[3] https://info.izumiinternational.com/3-advantages-of-aluminium-extrusion-frames-over-welded-steel

[4] https://www.wellste.com/aluminum-picture-frame-extrusions/

[5] https://www.youtube.com/watch?v=msIBFiahdzk

[6] https://www.youtube.com/watch?v=gJIChIs4g6A

[7] https://eagle-aluminum.com/benefits-of-aluminum-extrusions/

[8] https://vention.io/resources/guides/t-slot-aluminum-extrusion-structure-design-guide-77

[9] https://www.flexmation.com/blog/the-advantages-of-aluminum-framing-over-steel-framing/

[10] https://www.alufabinc.com

[11] https://www.youtube.com/watch?v=pyqQhTDcKbA

[12] https://palettiusa.com/aluminum-framing

[13] https://shop.machinemfg.com/aluminum-framing-systems-advantages-and-disadvantages/

[14] https://www.mknorthamerica.com/photogallery/aluminum-framing/