Content Menu

● Understanding Aluminum Extrusion

● Benefits of Aluminum Extrusion Components

● Applications of Aluminum Extrusion Components

● The Process of Aluminum Extrusion

● Advantages in Specific Industries

>> Construction Industry

>> Automotive Industry

>> Aerospace Industry

● Sustainability of Aluminum Extrusions

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using aluminum extrusions?

>> 2. How does the aluminum extrusion process work?

>> 3. In which industries are aluminum extrusions commonly used?

>> 4. Why is sustainability important in aluminum extrusion?

>> 5. Can aluminum extrusions be customized?

Aluminum extrusion components have become integral to various industries due to their unique properties and advantages. This article explores the benefits of aluminum extrusions, their applications, and how they can enhance efficiency and sustainability in your industry.

Understanding Aluminum Extrusion

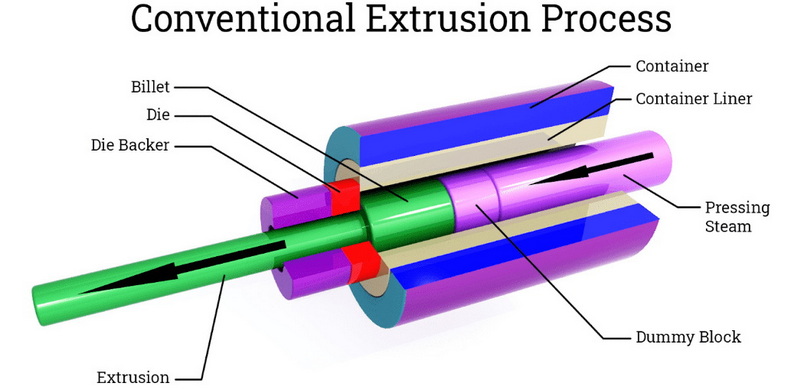

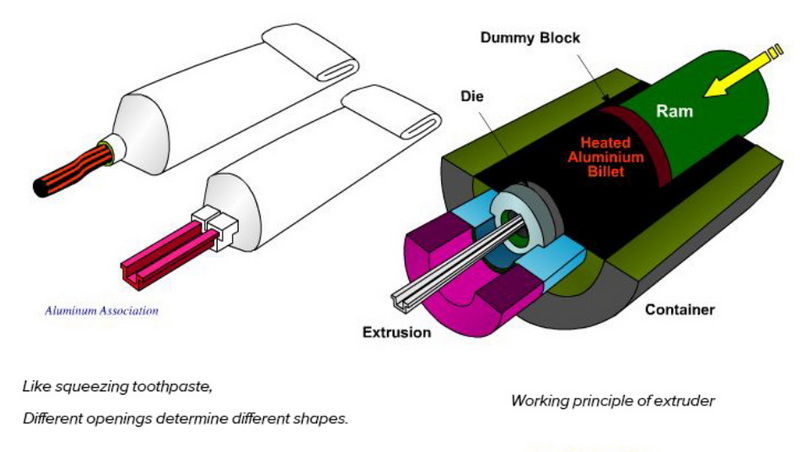

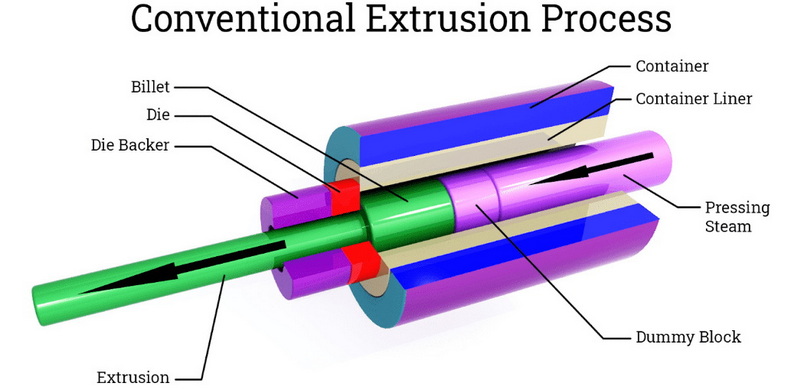

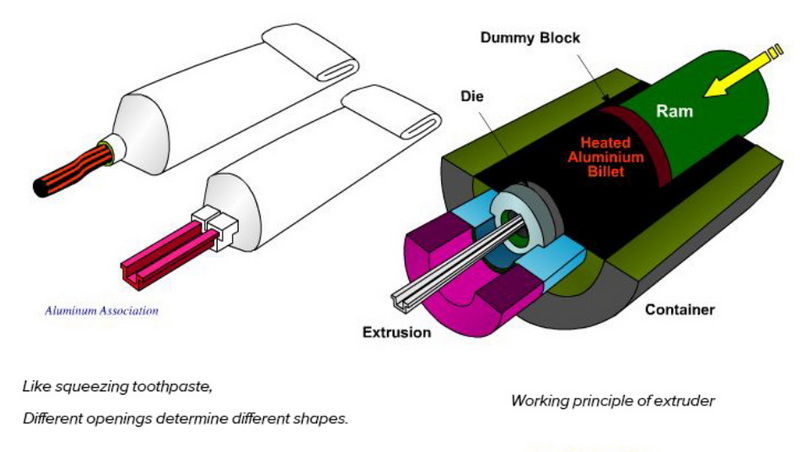

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die. This technique allows for the creation of complex cross-sectional shapes that are lightweight yet strong. The process begins with heating an aluminum billet, which is then pushed through a die, forming the desired shape as it exits.

Benefits of Aluminum Extrusion Components

Aluminum extrusion components offer numerous advantages that make them suitable for various applications:

- Lightweight: Aluminum is about one-third the weight of steel, making it easier to handle and transport.

- Strength: Despite its light weight, aluminum has a high strength-to-weight ratio, allowing for the construction of robust structures.

- Corrosion Resistance: The natural oxide layer that forms on aluminum protects it from corrosion, making it ideal for outdoor and marine applications.

- Customizability: The extrusion process allows for a wide range of shapes and sizes, enabling manufacturers to produce custom components tailored to specific needs.

- Sustainability: Aluminum is 100% recyclable without loss of quality, contributing to sustainable manufacturing practices.

- Cost-Effectiveness: The efficient production process reduces waste and lowers costs compared to other materials.

Applications of Aluminum Extrusion Components

Aluminum extrusions are utilized across various industries due to their versatility. Here are some common applications:

- Construction: Used in window frames, doors, and structural components due to their strength and aesthetic appeal.

- Automotive: Employed in vehicle frames, body panels, and heat exchangers because of their lightweight nature and durability.

- Aerospace: Critical for aircraft structures where weight reduction is essential without compromising strength.

- Electronics: Used in heat sinks and enclosures due to excellent thermal conductivity.

- Furniture: Commonly found in modern furniture designs that require both style and functionality.

The Process of Aluminum Extrusion

Understanding the extrusion process can help industries appreciate the benefits of aluminum components. Here's a brief overview:

1. Billet Preparation: An aluminum billet is heated to around 900°F (482°C) until it becomes malleable.

2. Extrusion: The heated billet is placed into an extrusion press where a hydraulic ram pushes it through a die.

3. Cooling: After exiting the die, the extruded shape is cooled using air or water.

4. Cutting and Finishing: The extruded lengths are cut to size and may undergo additional finishing processes like anodizing or painting.

Advantages in Specific Industries

Construction Industry

In construction, aluminum extrusions are favored for their lightweight yet strong properties. They provide structural integrity while allowing for innovative architectural designs. Additionally, their resistance to corrosion ensures longevity in various environmental conditions.

Automotive Industry

The automotive sector benefits significantly from aluminum extrusions as they contribute to fuel efficiency by reducing vehicle weight. Components such as chassis parts and engine blocks made from aluminum help manufacturers meet stringent fuel economy regulations while maintaining safety standards.

Aerospace Industry

In aerospace applications, reducing weight is crucial for improving fuel efficiency. Aluminum extrusions provide the necessary strength without adding excessive weight, making them ideal for aircraft frames and components.

Sustainability of Aluminum Extrusions

The sustainability aspect of aluminum extrusions cannot be overstated. As one of the most recyclable materials available, aluminum can be reused multiple times without degrading its properties. This not only reduces waste but also minimizes energy consumption during production compared to primary aluminum manufacturing.

Conclusion

Aluminum extrusion components offer significant benefits across various industries, including construction, automotive, aerospace, and electronics. Their lightweight nature, strength, corrosion resistance, customizability, cost-effectiveness, and sustainability make them an ideal choice for manufacturers looking to enhance their products' performance while adhering to environmental standards. As industries continue to evolve towards more sustainable practices, aluminum extrusions will play a pivotal role in shaping the future of manufacturing.

Frequently Asked Questions

1. What are the main advantages of using aluminum extrusions?

Aluminum extrusions are lightweight yet strong, resistant to corrosion, customizable in shape and size, cost-effective due to low waste production, and fully recyclable.

2. How does the aluminum extrusion process work?

The process involves heating an aluminum billet until it becomes malleable, pushing it through a die using a hydraulic press, cooling the extruded shape, and then cutting it to size.

3. In which industries are aluminum extrusions commonly used?

Common industries include construction (for window frames and structural components), automotive (for lightweight vehicle parts), aerospace (for aircraft structures), electronics (for heat sinks), and furniture design.

4. Why is sustainability important in aluminum extrusion?

Sustainability is vital because aluminum can be recycled indefinitely without losing quality. This reduces waste and energy consumption compared to producing new aluminum from raw materials.

5. Can aluminum extrusions be customized?

Yes! Aluminum extrusions can be tailored to meet specific design requirements in terms of shape, size, and finish, making them suitable for various applications across different industries.