Content Menu

● Understanding Aluminum Extrusions

● Comparison with Other Sizes

>> 15mm x 15mm Aluminum Extrusion

>> 30mm x 30mm Aluminum Extrusion

>> 40mm x 40mm Aluminum Extrusion

● Advantages of 20mm x 20mm Aluminum Extrusions

>> Versatility

>> Strength-to-Weight Ratio

>> Easy Assembly

>> Corrosion Resistance

>> Aesthetic Appeal

● Considerations When Choosing Aluminum Extrusions

>> Load Requirements

>> Space Constraints

>> Assembly Complexity

>> Environmental Conditions

>> Budget

● Applications of 20mm x 20mm Aluminum Extrusions

>> Industrial Automation

>> Furniture Design

>> DIY Projects

>> Transportation

>> Architectural Applications

● Conclusion

● Frequently Asked Questions

>> 1. What are the common applications for 20mm x 20mm aluminum extrusions?

>> 2. How does the strength of 20mm x 20mm aluminum extrusions compare to larger profiles?

>> 3. Can I use 20mm x 20mm aluminum extrusions for outdoor projects?

>> 4. What tools do I need to assemble aluminum extrusions?

>> 5. Are there any design limitations with aluminum extrusions?

Aluminum extrusions are a popular choice in various industries due to their lightweight, strength, and versatility. Among the many sizes available, the 20mm x 20mm aluminum extrusion profile stands out for its unique balance of size and functionality. This article will explore how 20mm x 20mm aluminum extrusions compare to other sizes, their applications, advantages, and considerations when choosing the right extrusion for your project.

Understanding Aluminum Extrusions

Aluminum extrusion is a process that involves forcing aluminum alloy through a die to create a specific cross-sectional shape. This method allows for the production of complex shapes that can be used in various applications, from structural components to decorative elements. The extrusion process is efficient and cost-effective, making it a preferred choice for manufacturers.

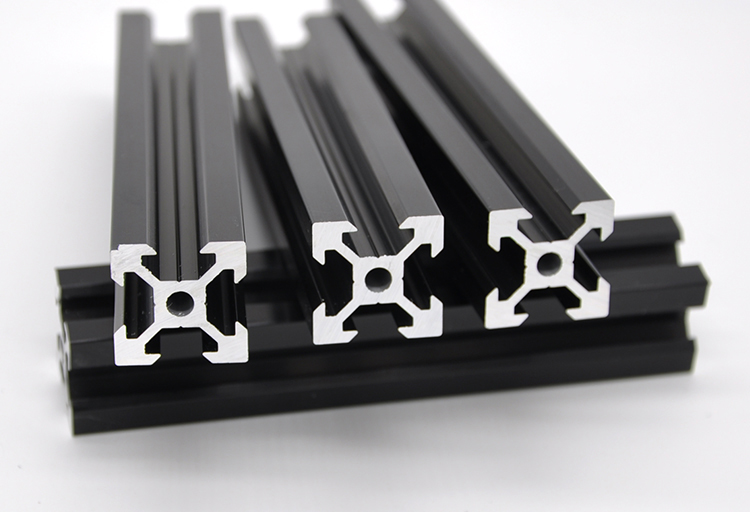

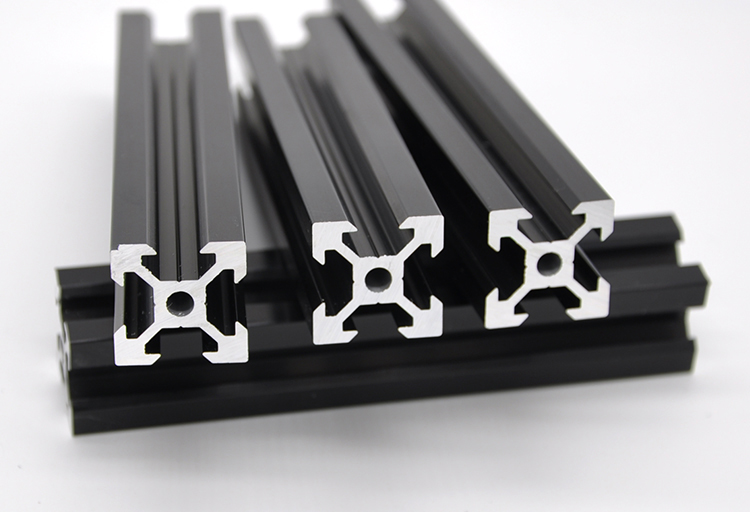

The 20mm x 20mm aluminum extrusion profile is part of the 20 Series, which is characterized by its square shape and T-slot design. This profile features four open T-slots, one on each face, allowing for easy attachment of accessories and components. The dimensions make it suitable for a wide range of applications, including:

- Frameworks for machines and equipment

- Workstations and assembly lines

- Display stands and shelving units

- Robotics and automation systems

Comparison with Other Sizes

When comparing the 20mm x 20mm aluminum extrusion to other sizes, several factors come into play, including strength, weight, and application suitability. Here's how it stacks up against some common alternatives:

15mm x 15mm Aluminum Extrusion

The 15mm x 15mm profile is smaller and lighter than the 20mm x 20mm profile. While it is suitable for lightweight applications, it may not provide the same structural integrity as the larger profile. The 15mm x 15mm extrusion is often used in smaller projects, such as:

- Lightweight frames

- Small enclosures

- DIY projects

The reduced size of the 15mm x 15mm profile makes it ideal for applications where space is limited, but it may not be the best choice for projects requiring significant strength or load-bearing capacity.

30mm x 30mm Aluminum Extrusion

On the other end of the spectrum, the 30mm x 30mm aluminum extrusion offers greater strength and rigidity. This profile is ideal for heavy-duty applications where additional load-bearing capacity is required. Common uses include:

- Industrial machinery

- Heavy-duty shelving

- Structural supports

The increased size does come with added weight, which may not be suitable for all applications. However, for projects that demand higher strength, the 30mm x 30mm profile is an excellent choice.

40mm x 40mm Aluminum Extrusion

The 40mm x 40mm profile is even larger and is typically used in applications requiring maximum strength and stability. This size is often found in:

- Large machinery frames

- Heavy-duty workstations

- Robotic arms

While the 40mm x 40mm extrusion provides excellent strength, it may be overkill for projects that do not require such robust support. The added weight and cost may also be a consideration for some applications.

Advantages of 20mm x 20mm Aluminum Extrusions

The 20mm x 20mm aluminum extrusion profile offers several advantages that make it a popular choice among engineers and designers:

Versatility

The 20mm x 20mm profile is versatile enough to be used in various applications, from lightweight structures to more robust frameworks. Its T-slot design allows for easy assembly and modification, making it ideal for prototyping and custom projects. This adaptability is particularly beneficial in industries where requirements can change rapidly.

Strength-to-Weight Ratio

This profile provides an excellent strength-to-weight ratio, making it suitable for applications where weight is a concern. It can support significant loads while remaining lightweight, which is crucial in industries like aerospace and automotive. The ability to maintain structural integrity without adding unnecessary weight is a key advantage of the 20mm x 20mm profile.

Easy Assembly

The T-slot design simplifies the assembly process. Users can quickly connect multiple profiles using standard fasteners, reducing the time and effort required for construction. This ease of assembly is particularly advantageous in environments where rapid prototyping and adjustments are necessary.

Corrosion Resistance

Aluminum is naturally resistant to corrosion, making it suitable for both indoor and outdoor applications. The 20mm x 20mm profile can withstand various environmental conditions without degrading. This property is essential for applications exposed to moisture or chemicals, ensuring longevity and reliability.

Aesthetic Appeal

The clean lines and modern appearance of aluminum extrusions make them visually appealing. This is particularly important in applications where aesthetics matter, such as in retail displays or architectural features. The ability to combine functionality with visual appeal is a significant advantage of using aluminum extrusions.

Considerations When Choosing Aluminum Extrusions

When selecting the right aluminum extrusion for your project, consider the following factors:

Load Requirements

Determine the load requirements of your application. If you need to support heavy loads, consider larger profiles like the 30mm x 30mm or 40mm x 40mm. For lighter applications, the 20mm x 20mm or even smaller profiles may suffice. Understanding the load requirements is crucial for ensuring the safety and effectiveness of your design.

Space Constraints

Evaluate the available space for your project. If you have limited space, the 20mm x 20mm profile may be the best choice due to its compact size. In contrast, larger profiles may not fit in tight spaces, limiting their usability in certain applications.

Assembly Complexity

Consider how complex your assembly will be. If you require frequent modifications or adjustments, the T-slot design of the 20mm x 20mm profile allows for easy reconfiguration. This flexibility is particularly beneficial in dynamic environments where designs may need to evolve over time.

Environmental Conditions

Think about the environmental conditions your extrusion will face. If it will be exposed to moisture or chemicals, ensure that the aluminum is treated or coated appropriately to enhance its corrosion resistance. Selecting the right finish can significantly impact the longevity and performance of the extrusion.

Budget

Finally, consider your budget. While aluminum extrusions are generally cost-effective, larger profiles may increase material costs. Balance your needs with your budget to find the best solution. It's essential to weigh the benefits of each profile against its cost to make an informed decision.

Applications of 20mm x 20mm Aluminum Extrusions

The versatility of the 20mm x 20mm aluminum extrusion profile allows it to be used in a wide range of applications across various industries. Some notable applications include:

Industrial Automation

In industrial automation, the 20mm x 20mm profile is often used to create frames for robotic arms, conveyor systems, and machine guards. Its strength and lightweight nature make it ideal for applications where precision and reliability are critical.

Furniture Design

The clean lines and modern aesthetic of the 20mm x 20mm aluminum extrusion make it a popular choice in furniture design. Designers use it to create stylish and functional pieces, such as desks, shelving units, and display stands.

DIY Projects

For DIY enthusiasts, the 20mm x 20mm profile offers endless possibilities. Its ease of assembly and adaptability make it a favorite for building custom projects, from home improvement tasks to hobbyist creations.

Transportation

In the transportation industry, the 20mm x 20mm aluminum extrusion is used in the construction of lightweight frames for vehicles, trailers, and equipment. Its strength-to-weight ratio is crucial for improving fuel efficiency and performance.

Architectural Applications

Architects and builders often use the 20mm x 20mm profile in architectural applications, such as curtain walls, canopies, and structural supports. Its aesthetic appeal and structural integrity make it a valuable material in modern construction.

Conclusion

In conclusion, the 20mm x 20mm aluminum extrusion profile is a versatile and practical choice for a wide range of applications. Its balance of strength, weight, and ease of assembly makes it suitable for both light and moderate load-bearing projects. When compared to other sizes, it offers unique advantages that can be leveraged in various industries.

As you consider your next project, weigh the benefits of the 20mm x 20mm profile against your specific requirements. Whether you need a lightweight solution for a DIY project or a robust framework for industrial machinery, understanding the differences between aluminum extrusion sizes will help you make an informed decision.

Frequently Asked Questions

1. What are the common applications for 20mm x 20mm aluminum extrusions?

Common applications include machine frames, workstations, display stands, and robotics.

2. How does the strength of 20mm x 20mm aluminum extrusions compare to larger profiles?

While the 20mm x 20mm profile is strong, larger profiles like 30mm x 30mm and 40mm x 40mm offer greater load-bearing capacity.

3. Can I use 20mm x 20mm aluminum extrusions for outdoor projects?

Yes, aluminum is naturally corrosion-resistant, making it suitable for outdoor applications.

4. What tools do I need to assemble aluminum extrusions?

Basic tools include a saw for cutting, a drill for making holes, and standard fasteners for assembly.

5. Are there any design limitations with aluminum extrusions?

While aluminum extrusions are versatile, complex shapes may require custom dies, which can increase costs.