Content Menu

● The Alueuropa Aluminum Extrusion Factory: An Overview

● The Day of the Fire

>> Eyewitness Accounts

● The Fire's Rapid Spread

>> Structural Challenges

● Emergency Response Efforts

>> Community Support for First Responders

● Impact on Employees and Community

>> Employee Experiences Post-Fire

>> Community Reaction

● Environmental Concerns

>> Long-term Environmental Impact

● Investigating Causes

>> Findings from Investigations

● Lessons Learned

>> Importance of Safety Culture

● Conclusion

● Related Questions

>> 1. What Were the Main Causes of the Alueuropa Factory Fire?

>> 2. How Did Employees React During the Fire?

>> 3. What Environmental Risks Were Associated with the Fire?

>> 4. What Safety Measures Should Factories Implement After This Incident?

>> 5. How Has the Community Responded to Support Affected Workers?

The Alueuropa aluminum extrusion factory fire, which occurred in Seville, Spain, has been described by witnesses as a catastrophic event that transformed the facility into a scene reminiscent of a "portal to hell." This dramatic characterization reflects the intensity and chaos of the fire that engulfed one of the leading aluminum extrusion factories in Europe. In this article, we will explore the circumstances surrounding the fire, its impact on the community and industry, and the lessons learned from this tragic incident.

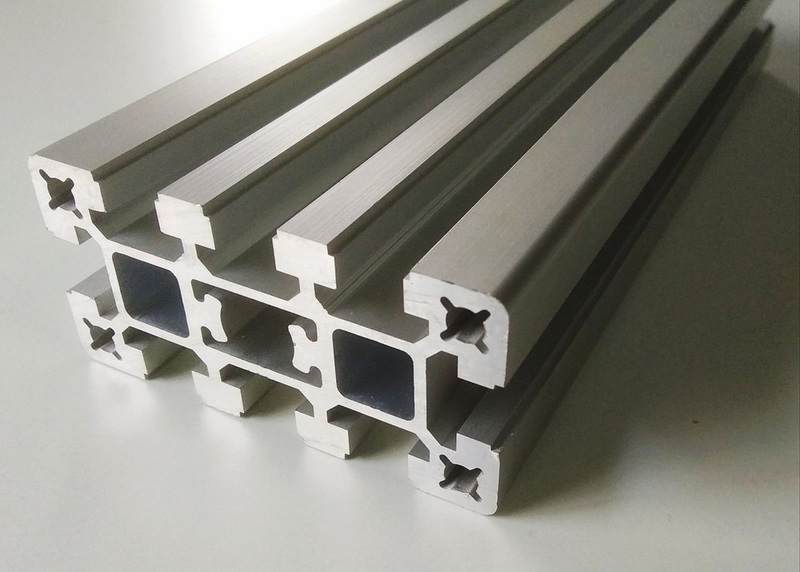

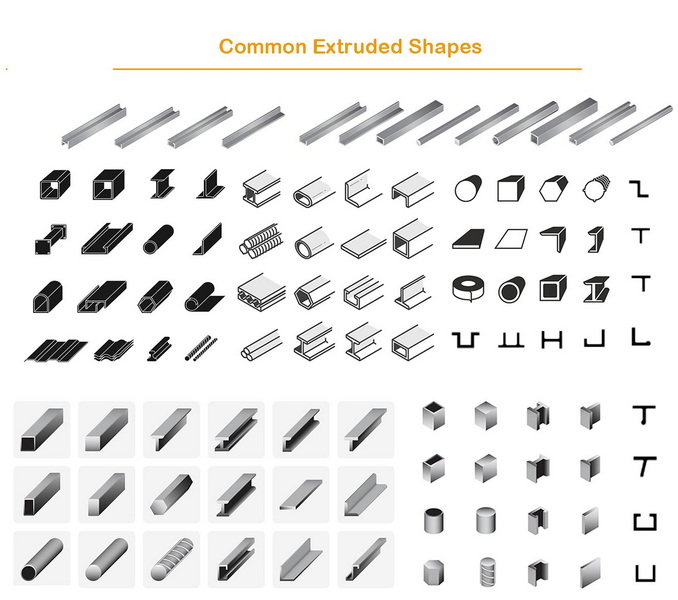

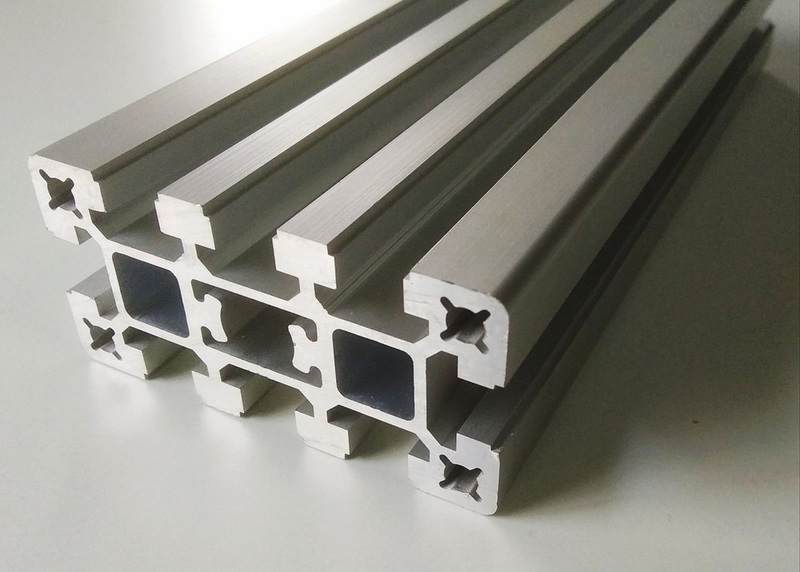

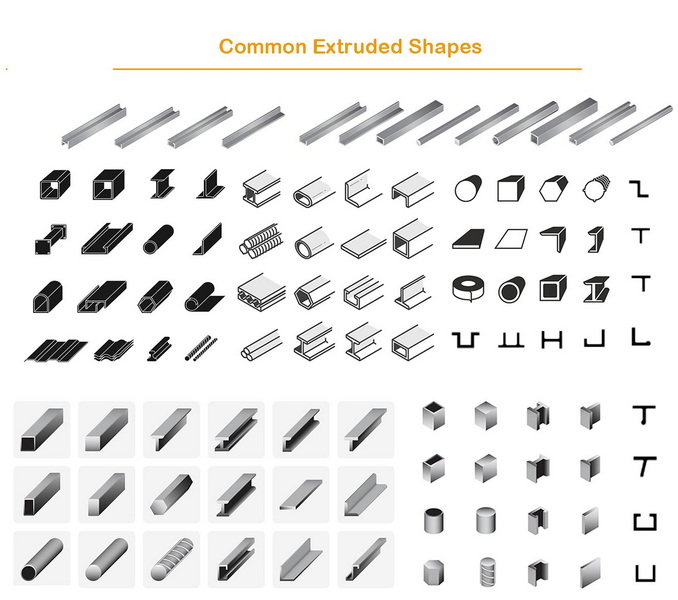

The Alueuropa Aluminum Extrusion Factory: An Overview

Alueuropa is known for its advanced aluminum extrusion processes, producing a wide range of products used in various industries, including construction, automotive, and aerospace. The factory's strategic location in Seville allowed it to serve a significant market in Southern Europe. However, the events of that fateful day would change everything.

Founded in the early 2000s, Alueuropa quickly became a key player in the aluminum industry. The factory employed hundreds of workers and was renowned for its commitment to quality and innovation. With state-of-the-art machinery and a skilled workforce, Alueuropa was poised for growth. However, like many industrial facilities, it faced inherent risks associated with its operations.

The Day of the Fire

On the morning of [insert date], employees arrived at the Alueuropa factory as usual. However, within hours, an ordinary day turned into a nightmare. Reports indicate that the fire started in one of the production areas, quickly spreading due to flammable materials and poor ventilation.

Eyewitness Accounts

Witnesses described seeing thick black smoke billowing from the factory, with flames licking at the sky. Many reported hearing explosions as gas canisters ignited within the facility. The scene was chaotic as employees attempted to evacuate while firefighters rushed to contain the blaze.

One employee recounted how they first noticed a small flame near one of the extrusion machines. "At first, it seemed manageable," they said. "But within minutes, it grew out of control." As alarms sounded throughout the building, panic set in among workers who struggled to find exits amid thick smoke.

The Fire's Rapid Spread

The rapid spread of the fire was exacerbated by several factors:

- Flammable Materials: The factory housed various flammable substances used in aluminum extrusion processes.

- Ventilation Issues: Poor ventilation allowed smoke and heat to accumulate, intensifying the fire.

- Delayed Response: Initial reports suggest that there was a delay in activating emergency protocols.

As flames engulfed production lines and storage areas, firefighters faced an uphill battle against an inferno fueled by combustible materials. Reports indicated that some employees attempted to extinguish small fires using available extinguishers but were quickly overwhelmed.

Structural Challenges

The structure of the factory also played a role in how quickly the fire spread. Many industrial buildings are designed with large open spaces for machinery and production lines; while this layout is efficient for manufacturing, it can also facilitate rapid fire spread if not adequately compartmentalized.

Emergency Response Efforts

Firefighters from across Seville responded to the emergency call. Their efforts were hampered by difficult conditions, including:

- High Temperatures: The intense heat made it challenging for firefighters to approach the flames.

- Structural Integrity: As the fire raged on, parts of the building began to collapse, posing additional risks.

Despite these challenges, firefighters worked tirelessly to control the blaze and prevent it from spreading to nearby industrial facilities. Aerial units were deployed to drop water from above while ground crews battled flames at various entry points.

Firefighters Battling Flames

Community Support for First Responders

The local community showed immense support for first responders during this crisis. Residents brought food and water to firefighters working long hours at the scene. Local businesses offered supplies and assistance as they witnessed their community come together in times of need.

Impact on Employees and Community

The Alueuropa factory fire had devastating effects on employees and the surrounding community. Fortunately, most employees were able to evacuate safely; however, several individuals sustained injuries due to smoke inhalation and burns.

Employee Experiences Post-Fire

In the aftermath of the fire, many employees faced uncertainty regarding their future employment. With extensive damage reported throughout the facility, workers were left wondering when or if they would return to their jobs. The emotional toll was evident as many grappled with trauma from their experiences during the evacuation.

Community Reaction

The local community rallied around those affected by the fire. Fundraising efforts were initiated to support displaced workers and their families. Local businesses also stepped up to provide assistance. Events such as bake sales and charity runs became common as residents sought ways to help their neighbors rebuild their lives after this disaster.

Environmental Concerns

The aftermath of the Alueuropa aluminum extrusion factory fire raised significant environmental concerns.

- Air Quality: The smoke released into the atmosphere contained harmful chemicals that could affect air quality in surrounding areas.

- Water Contamination: Runoff from firefighting efforts raised fears of water contamination in nearby rivers and streams.

Authorities conducted environmental assessments to monitor potential impacts on public health and safety. Local environmental agencies tested air samples for pollutants while monitoring waterways for any signs of contamination from runoff or debris caused by firefighting efforts.

Long-term Environmental Impact

Experts warned that prolonged exposure to pollutants released during such fires could have lasting effects on both human health and local ecosystems. Communities near industrial sites must remain vigilant about monitoring air quality and water safety following incidents like this one.

Investigating Causes

In response to this disaster, investigators launched a thorough inquiry into its causes. Key areas of focus included:

- Safety Protocols: Were existing safety measures adequate?

- Maintenance Records: Was there a history of maintenance issues that could have contributed?

- Employee Training: Were employees adequately trained to respond to emergencies?

Findings from Investigations

Preliminary findings indicated that while safety protocols existed, they were not effectively implemented or followed. This raised questions about workplace culture regarding safety awareness. Investigators uncovered lapses in routine inspections and maintenance schedules that may have contributed to hazardous conditions within production areas.

Lessons Learned

The Alueuropa aluminum extrusion factory fire serves as a stark reminder of the importance of safety in industrial settings. Key lessons include:

- Regular Safety Drills: Conducting frequent safety drills can prepare employees for emergencies.

- Improved Ventilation Systems: Upgrading ventilation systems can help prevent fires from spreading rapidly.

- Emergency Response Training: Ensuring all employees are trained in emergency response can save lives during crises.

Importance of Safety Culture

Creating a robust safety culture within organizations is essential for preventing future incidents like this one. Employees should feel empowered to speak up about unsafe conditions without fear of retaliation or dismissal. Regular training sessions should be integrated into company practices so that all staff members remain informed about best practices regarding workplace safety.

Conclusion

The Alueuropa aluminum extrusion factory fire was a tragic event that highlighted critical gaps in safety protocols within industrial environments. While many escaped unharmed, including most employees who managed successful evacuations despite chaos unfolding around them, this incident serves as a cautionary tale for factories worldwide about prioritizing safety measures over productivity goals or profit margins alone.

By learning from this disaster and implementing stronger safety measures—such as regular training drills focused on emergency preparedness—companies can work towards preventing similar tragedies in future operations while fostering environments where workers feel safe reporting hazards without hesitation or fear of consequences attached thereto.

Related Questions

1. What Were the Main Causes of the Alueuropa Factory Fire?

The main causes included flammable materials present in production areas, poor ventilation that allowed heat and smoke accumulation, and delays in emergency response activation.

2. How Did Employees React During the Fire?

Most employees managed to evacuate safely; however, some experienced injuries due to smoke inhalation and burns while attempting to escape.

3. What Environmental Risks Were Associated with the Fire?

Concerns included potential air quality degradation due to smoke release and water contamination from runoff during firefighting efforts.

4. What Safety Measures Should Factories Implement After This Incident?

Factories should conduct regular safety drills, improve ventilation systems, and ensure comprehensive emergency response training for all employees.

5. How Has the Community Responded to Support Affected Workers?

The local community initiated fundraising efforts and provided assistance through local businesses to support displaced workers and their families after the fire.