Content Menu

● Introduction

● Benefits of Using Aluminum Extrusions

● Tools and Materials Needed

>> Tools

>> Materials

● Step-by-Step Guide to Building the Fence

>> Measuring and Planning

>> Cutting the Aluminum Extrusions

>> Assembling the Fence

>> Installing the Fence on the Table Saw

● Enhancements and Customizations

● Conclusion

>> Related Questions

● 1. What are the advantages of using aluminum for a table saw fence?

● 2. How do I measure my table saw for a new fence?

● 3. Can I make my table saw fence adjustable?

● 4. What tools do I need to build a table saw fence?

● 5. How can I enhance my aluminum table saw fence?

Introduction

Upgrading your table saw can significantly enhance your woodworking experience, making it safer, more efficient, and more precise. One of the best ways to achieve this is by incorporating aluminum extrusion for your table saw fence. Aluminum extrusions are lightweight, durable, and versatile, making them an ideal choice for creating a custom fence that meets your specific needs. In this article, we will explore the benefits of using aluminum extrusions, provide a step-by-step guide on how to build your own table saw fence, and discuss various enhancements you can make to improve functionality.

Benefits of Using Aluminum Extrusions

Aluminum extrusions offer numerous advantages when used for table saw fences. Here are some key benefits:

- Durability and Strength: Aluminum is known for its strength-to-weight ratio, making it a robust material that can withstand the rigors of woodworking. Unlike wood, aluminum does not warp or swell, ensuring that your fence remains straight and true over time.

- Lightweight and Ease of Handling: One of the most significant advantages of aluminum is its lightweight nature. This makes it easy to handle and adjust, allowing for quick modifications and repositioning without straining your back.

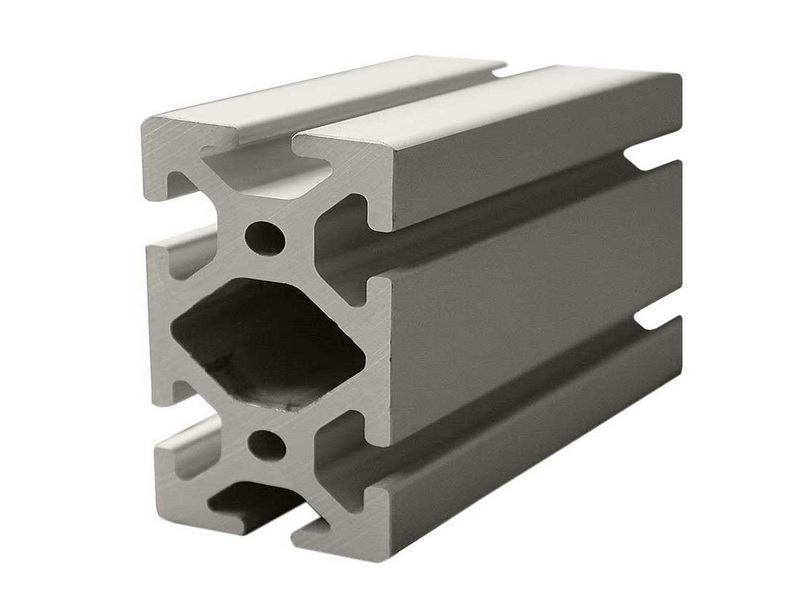

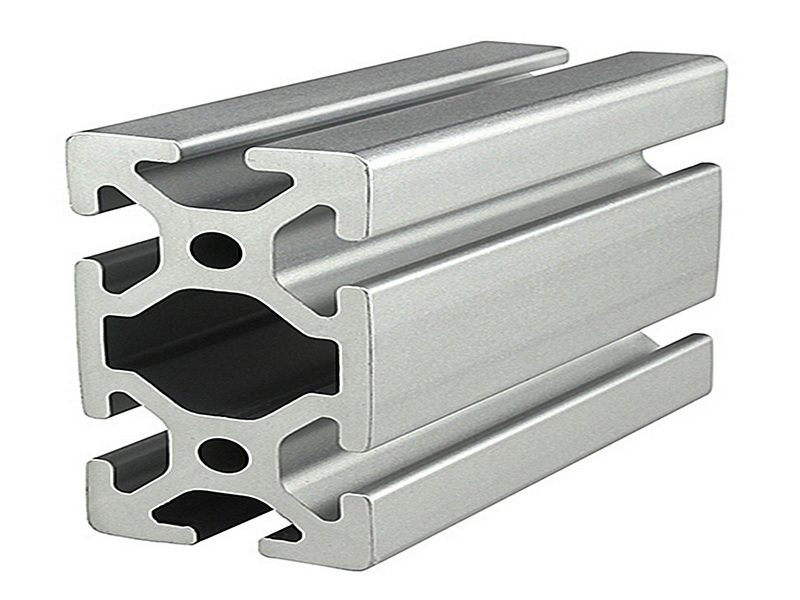

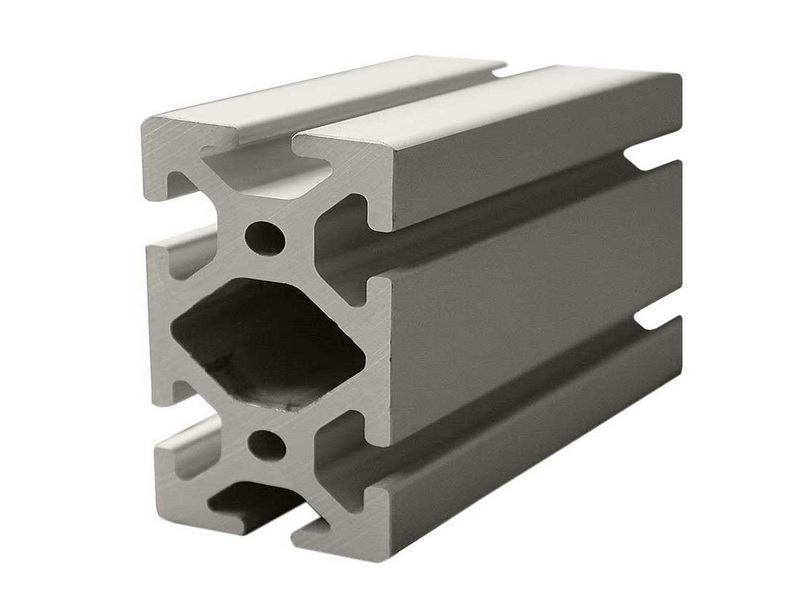

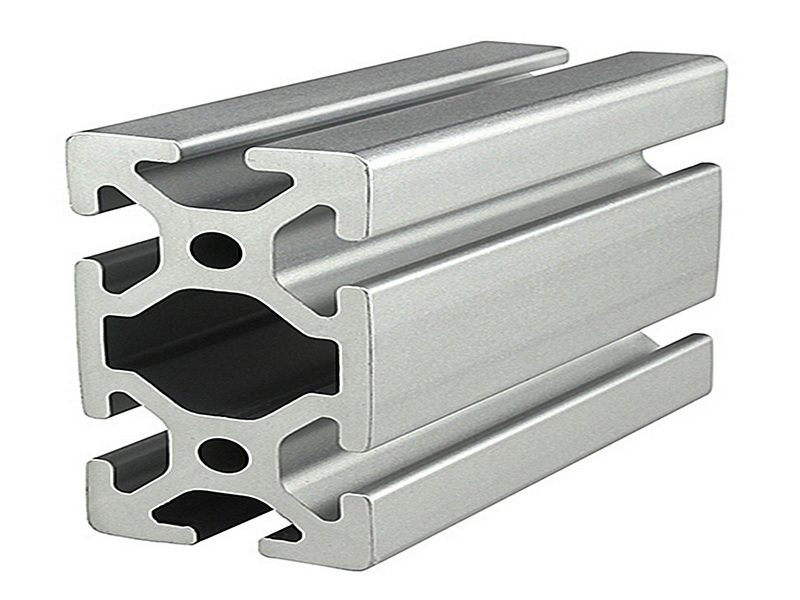

- Versatility in Design and Application: Aluminum extrusions come in various shapes and sizes, allowing you to customize your table saw fence to fit your specific requirements. Whether you need a simple straight edge or a more complex design with T-slots for jigs, aluminum can accommodate your needs.

Tools and Materials Needed

Before you begin building your custom table saw fence, gather the following tools and materials:

Tools

- Table saw

- Miter saw or hacksaw

- Drill and drill bits

- Measuring tape

- Square

- Clamps

- Screwdriver

- Level

Materials

- Aluminum extrusions (choose the appropriate size and shape for your design)

- Fasteners (screws, bolts, and nuts)

- T-slots (if desired for additional functionality)

- Wood or plastic end caps (to finish the ends of the extrusions)

Step-by-Step Guide to Building the Fence

Measuring and Planning

The first step in upgrading your table saw with aluminum extrusion is to measure your table saw accurately. Start by determining the width of your table saw and the desired length of your fence. A good rule of thumb is to make the fence at least as long as the width of your table saw to ensure maximum support for your workpieces.

Once you have your measurements, sketch a simple design of your fence. Consider whether you want a fixed fence or an adjustable one. If you opt for an adjustable fence, plan for the necessary mechanisms to allow for easy adjustments.

Cutting the Aluminum Extrusions

With your measurements and design in hand, it's time to cut the aluminum extrusions to size. Use a miter saw or hacksaw to make clean, straight cuts. Ensure that you wear safety goggles and gloves to protect yourself during this process.

When cutting, it's essential to measure twice and cut once to avoid mistakes. If you're using T-slots, make sure to cut them to the appropriate length as well.

Assembling the Fence

Once you have all your pieces cut, it's time to assemble the fence. Start by laying out the aluminum extrusions according to your design. Use clamps to hold the pieces in place while you drill holes for the fasteners.

If you're using T-slots, insert the T-nuts into the slots before securing the pieces together. This will allow you to attach additional accessories later on. Use screws or bolts to secure the extrusions together, ensuring that everything is aligned correctly.

Installing the Fence on the Table Saw

After assembling the fence, it's time to install it on your table saw. Position the fence on the table saw's surface and use a level to ensure it is perfectly straight. Once you're satisfied with the alignment, secure the fence in place using clamps or bolts.

If you've designed an adjustable fence, make sure to test the adjustment mechanism to ensure it operates smoothly.

Enhancements and Customizations

Once your aluminum extrusion table saw fence is installed, you can consider various enhancements to improve its functionality:

- Adding T-Slots for Jigs and Accessories: T-slots allow you to attach jigs, stops, and other accessories easily. This feature can significantly enhance the versatility of your table saw fence, making it suitable for a wide range of woodworking tasks.

- Options for Adjustable Features: If you haven't already, consider adding an adjustable feature to your fence. This can be achieved by incorporating a sliding mechanism that allows you to move the fence closer or further away from the blade, providing greater flexibility for different cuts.

- Incorporating Measuring Guides: Adding measuring guides to your fence can help you make precise cuts without needing to measure each time. You can use adhesive measuring tapes or engraved aluminum strips for this purpose.

- Finishing Touches: To give your fence a polished look, consider adding wood or plastic end caps to the exposed ends of the aluminum extrusions. This not only improves aesthetics but also prevents sharp edges that could cause injury.

Conclusion

Upgrading your table saw with aluminum extrusion for the fence is a worthwhile investment that can enhance your woodworking experience. The durability, lightweight nature, and versatility of aluminum make it an ideal choice for creating a custom fence that meets your specific needs. By following the steps outlined in this article, you can build a high-quality table saw fence that will improve your accuracy and efficiency in the workshop.

Related Questions

1. What are the advantages of using aluminum for a table saw fence?

Aluminum offers durability, lightweight handling, and resistance to warping, making it an excellent choice for a table saw fence.

2. How do I measure my table saw for a new fence?

Measure the width of your table saw and determine the desired length of your fence, ensuring it is at least as long as the saw for maximum support.

3. Can I make my table saw fence adjustable?

Yes, you can design your fence with a sliding mechanism to allow for easy adjustments, enhancing its versatility.

4. What tools do I need to build a table saw fence?

You will need a table saw, miter saw, drill, measuring tape, clamps, and a level, among other tools.

5. How can I enhance my aluminum table saw fence?

Consider adding T-slots for jigs, incorporating measuring guides, and finishing with end caps for a polished look.