Content Menu

● Introduction

● Understanding Aluminum Extrusion

>> Common Uses of Aluminum Extrusion

● Benefits of Affordable Aluminum Extrusions

>> Cost Savings

>> Versatility and Customization

>> Lightweight and Durable Properties

● Top Sources for Cheap Aluminum Extrusions

>> Online Retailers

>> Local Suppliers and Manufacturers

>> Tips for Finding the Best Deals

● Factors Influencing Aluminum Extrusion Pricing

>> Material Costs

>> Customization and Complexity

>> Minimum Order Quantities

● Conclusion

● Related Questions

>> 1. What are the advantages of using aluminum extrusion in construction?

>> 2. How can I find local suppliers for aluminum extrusions?

>> 3. What is the typical lead time for aluminum extrusion orders?

>> 4. Can I customize aluminum extrusions for my specific project?

>> 5. What are some common mistakes to avoid when ordering aluminum extrusions?

Introduction

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This versatile technique is widely used in various industries, including construction, automotive, and consumer goods. However, the cost of aluminum extrusion can be a significant factor for businesses and DIY enthusiasts alike. In this article, we will explore various strategies to save money on aluminum extrusion projects while ensuring quality and efficiency.

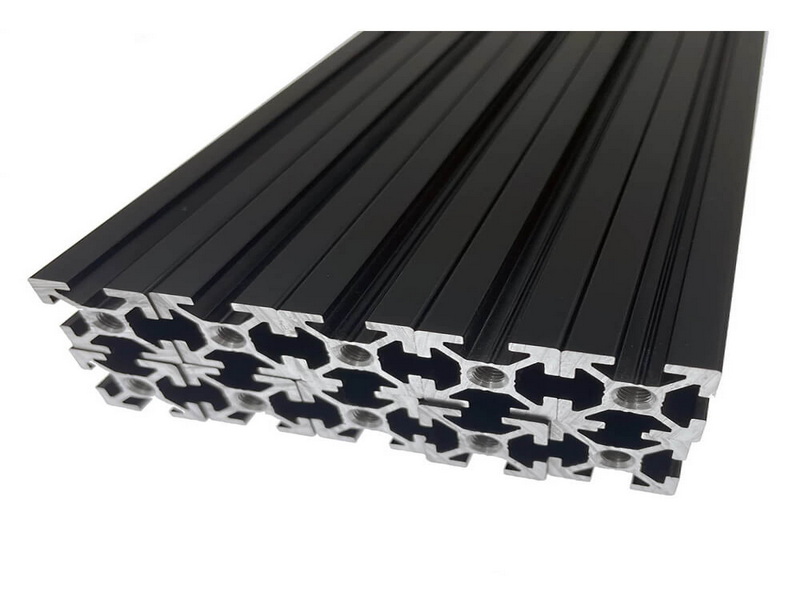

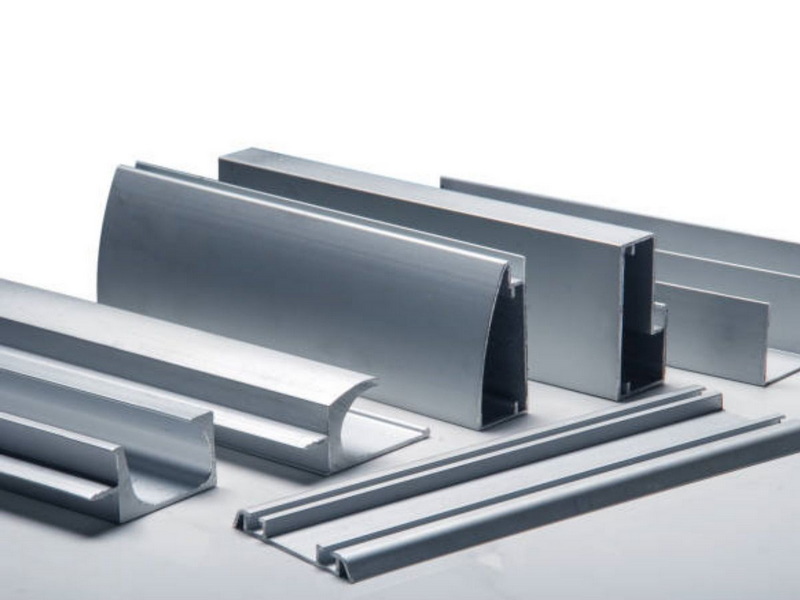

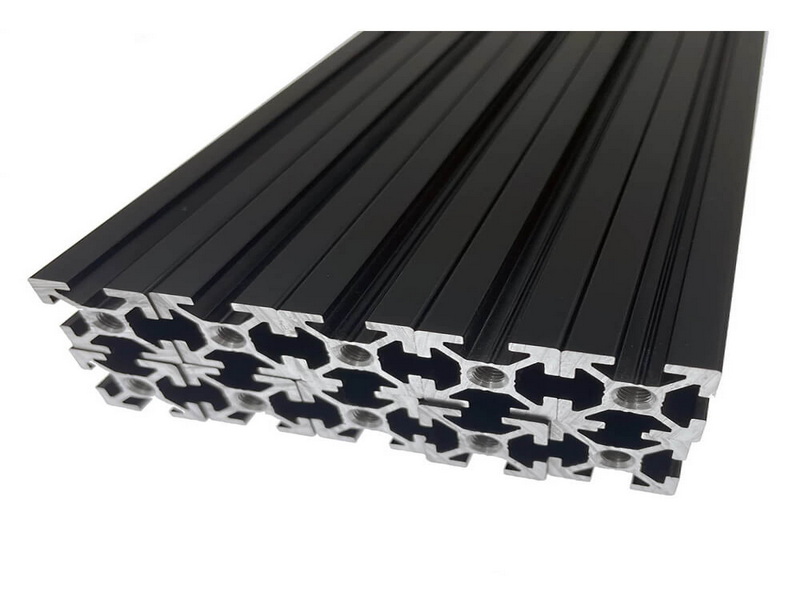

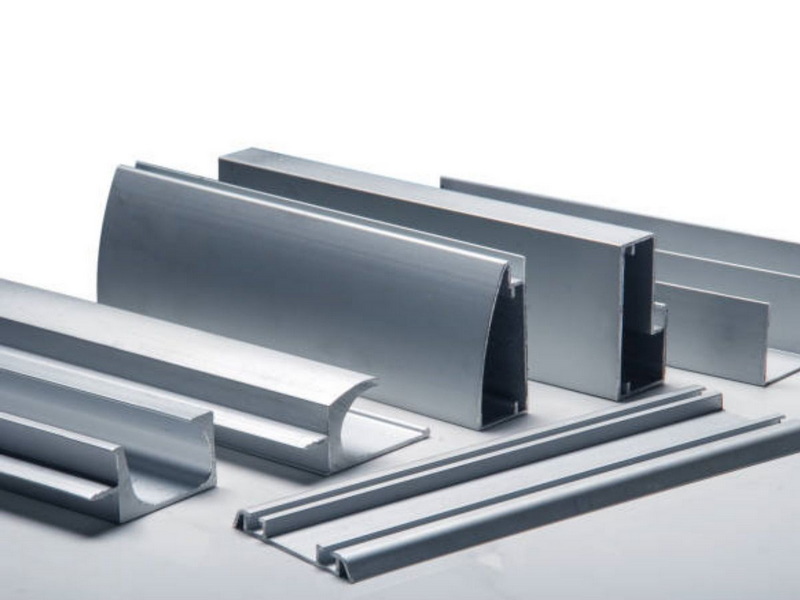

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum through a die to create a specific shape. This process allows for the production of complex profiles that can be used in a wide range of applications. The benefits of aluminum extrusion include its lightweight nature, corrosion resistance, and ability to be easily fabricated and assembled.

Common Uses of Aluminum Extrusion

Aluminum extrusions are used in numerous applications, such as:

- Construction: Window frames, doors, and structural components.

- Automotive: Lightweight parts that improve fuel efficiency.

- Consumer Products: Furniture, appliances, and electronic enclosures.

Understanding the various applications of aluminum extrusion can help you identify the best ways to utilize this material in your projects.

Benefits of Affordable Aluminum Extrusions

When considering aluminum extrusion for your projects, opting for affordable options can lead to significant cost savings. Here are some key benefits of using cheap aluminum extrusion:

Cost Savings

Choosing budget-friendly aluminum extrusions can drastically reduce your overall project costs. By sourcing materials at lower prices, you can allocate your budget to other essential aspects of your project, such as labor and design.

Versatility and Customization

Cheap aluminum extrusions come in various shapes and sizes, allowing for customization to meet specific project requirements. This versatility means you can find the right profile for your needs without overspending.

Lightweight and Durable Properties

Aluminum is known for its lightweight yet durable characteristics. Using affordable aluminum extrusions can help you create strong structures without adding unnecessary weight, which is particularly beneficial in applications like automotive and aerospace.

Top Sources for Cheap Aluminum Extrusions

Finding the right sources for cheap aluminum extrusions is crucial for saving money on your projects. Here are some tips on where to look:

Online Retailers

Many online retailers specialize in aluminum extrusions, offering competitive prices and a wide selection. Websites like Amazon and dedicated aluminum suppliers often have deals on bulk purchases, making it easier to find affordable options.

Local Suppliers and Manufacturers

Visiting local suppliers can provide opportunities to negotiate prices and find discounts. Many manufacturers offer lower prices for bulk orders or can provide recommendations for cost-effective solutions.

Tips for Finding the Best Deals

- Compare Prices: Always compare prices from multiple suppliers to ensure you are getting the best deal.

- Look for Promotions: Keep an eye out for seasonal promotions or clearance sales that can offer significant savings.

- Join Industry Groups: Networking with other professionals in the industry can lead to insider tips on where to find the best deals.

Factors Influencing Aluminum Extrusion Pricing

Understanding the factors that influence aluminum extrusion pricing can help you make informed decisions and minimize costs. Here are some key considerations:

Material Costs

The price of aluminum fluctuates based on market demand and availability. Keeping an eye on market trends can help you purchase materials at the right time, potentially saving you money.

Customization and Complexity

The more complex the design of your aluminum extrusion, the higher the cost may be. Simplifying your design or opting for standard profiles can help reduce expenses.

Minimum Order Quantities

Many suppliers have minimum order quantities that can affect pricing. If you only need a small amount of material, consider pooling orders with other projects or businesses to meet these minimums and take advantage of lower prices.

Conclusion

Saving money on aluminum extrusion projects is achievable with the right strategies. By understanding the benefits of affordable aluminum extrusions, exploring various sources, and being aware of the factors that influence pricing, you can effectively manage your project costs. Whether you are a business owner or a DIY enthusiast, these tips will help you make the most of your aluminum extrusion projects without compromising on quality.

Related Questions

1. What are the advantages of using aluminum extrusion in construction?

Aluminum extrusion offers lightweight, durable, and corrosion-resistant materials, making it ideal for construction applications such as window frames and structural components.

2. How can I find local suppliers for aluminum extrusions?

You can search online directories, visit local hardware stores, or attend industry trade shows to connect with local suppliers of aluminum extrusions.

3. What is the typical lead time for aluminum extrusion orders?

Lead times can vary based on the complexity of the order and the supplier's capacity, but typical lead times range from a few days to several weeks.

4. Can I customize aluminum extrusions for my specific project?

Yes, many suppliers offer customization options for aluminum extrusions, allowing you to create profiles that meet your specific project requirements.

5. What are some common mistakes to avoid when ordering aluminum extrusions?

Common mistakes include not verifying the dimensions, failing to compare prices from multiple suppliers, and overlooking the importance of understanding the material's properties for your specific application.