Content Menu

● Understanding 80 x 20 Aluminum Extrusion

● Benefits of Using 80 x 20 Aluminum Extrusion

● Customizing Your Design

>> Step 1: Define Your Project Requirements

>> Step 2: Choose the Right Components

>> Step 3: Design Your Layout

>> Step 4: Assemble Your Structure

>> Step 5: Finishing Touches

>> Step 6: Testing and Adjustments

● Applications of 80 x 20 Aluminum Extrusion

● Advanced Customization Techniques

>> Integrating Technology

>> Using CAD for Prototyping

>> Collaborative Design

>> Sustainability Considerations

● Conclusion

● Frequently Asked Questions

>> 1. What tools do I need to work with 80 x 20 aluminum extrusion?

>> 2. Can I use 80 x 20 aluminum extrusion for outdoor projects?

>> 3. How do I ensure my structure is stable?

>> 4. Is it possible to modify my design after assembly?

>> 5. Where can I find 80 x 20 aluminum extrusion components?

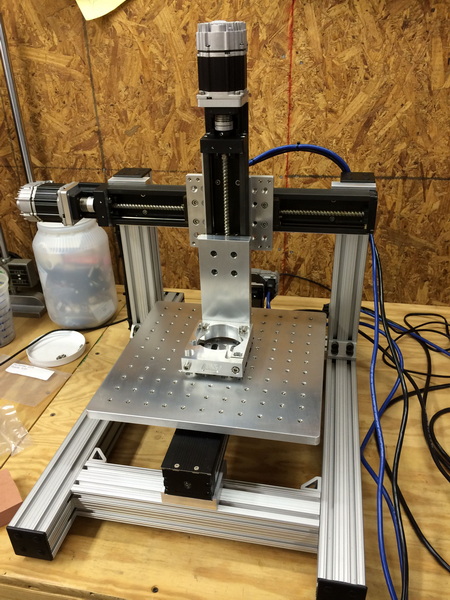

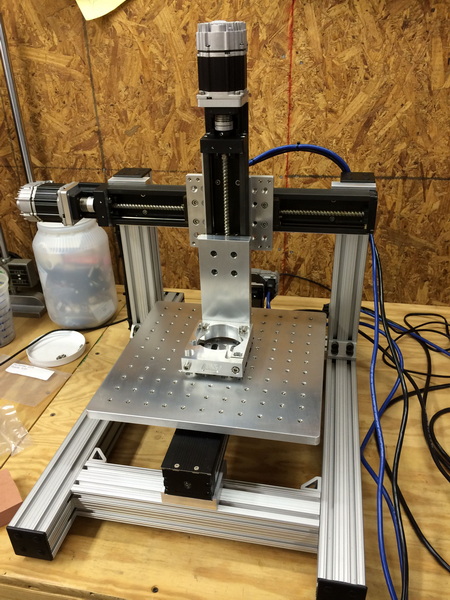

Aluminum extrusion has become a popular choice for various applications, particularly in the fields of engineering, architecture, and DIY projects. Among the many profiles available, the 80 x 20 aluminum extrusion stands out due to its versatility and ease of use. This article will explore how you can customize your design using 80 x 20 aluminum extrusion, providing insights into its applications, benefits, and practical tips for effective customization.

Understanding 80 x 20 Aluminum Extrusion

80 x 20 aluminum extrusion refers to a specific profile size, where the width is 80mm and the height is 20mm. This profile is part of a larger family of T-slot aluminum extrusions, which feature grooves along their lengths. These grooves allow for easy assembly and disassembly, making them ideal for modular designs. The T-slot design enables users to attach various components, such as brackets, panels, and other extrusions, without the need for complex tools or extensive machining.

Benefits of Using 80 x 20 Aluminum Extrusion

1. Versatility: The 80 x 20 profile can be used in a wide range of applications, from building frames for machinery to creating custom furniture and workstations.

2. Lightweight yet Strong: Aluminum is known for its strength-to-weight ratio, making it an excellent choice for structures that require durability without excessive weight.

3. Ease of Assembly: The T-slot design allows for quick and easy assembly, enabling users to create complex structures without specialized skills.

4. Modularity: Components can be easily added or removed, allowing for flexibility in design and functionality.

5. Aesthetic Appeal: Aluminum has a modern look that can enhance the visual appeal of any project, making it suitable for both industrial and home environments.

Customizing Your Design

Step 1: Define Your Project Requirements

Before diving into the customization process, it's essential to define the requirements of your project. Consider the following questions:

- What is the primary purpose of the structure?

- What dimensions do you need?

- Will the design need to accommodate any specific components or equipment?

- What weight will the structure need to support?

By answering these questions, you can create a clear outline of your project, which will guide your design process.

Step 2: Choose the Right Components

Once you have a clear understanding of your project requirements, the next step is to select the appropriate components. In addition to the 80 x 20 aluminum extrusion itself, you will need various accessories, including:

- Brackets: Used to connect different sections of the extrusion.

- Fasteners: Bolts, nuts, and screws that secure the components together.

- End Caps: These provide a finished look to the ends of the extrusions and can also prevent dirt and debris from entering the profile.

- Panels: If your design requires enclosures or surfaces, consider using panels made from materials like acrylic, polycarbonate, or aluminum.

Step 3: Design Your Layout

With your components selected, it's time to design your layout. You can use CAD software to create a detailed design, which will help visualize the final product. Many manufacturers of aluminum extrusions offer free design software that allows you to input your specifications and generate a 3D model of your project.

When designing your layout, consider the following:

- Dimensions: Ensure that all components fit together as intended.

- Weight Distribution: If your structure will support weight, plan for even distribution to avoid stress on any single point.

- Accessibility: Design your structure to allow for easy access to any components that may require maintenance or adjustment.

Step 4: Assemble Your Structure

Once your design is finalized, it's time to assemble your structure. Here are some tips for a successful assembly:

- Prepare Your Workspace: Ensure you have a clean, organized workspace with all your tools and components readily available.

- Follow Your Design: Use your CAD model as a reference to ensure that you are assembling the structure correctly.

- Use the Right Tools: While many assemblies can be done by hand, having the right tools, such as a torque wrench, can help ensure that fasteners are tightened to the correct specifications.

- Check for Squareness: As you assemble, periodically check that your structure is square. This will help prevent issues later on.

Step 5: Finishing Touches

After assembly, consider adding finishing touches to enhance the functionality and appearance of your structure:

- Surface Treatment: Anodizing or powder coating can improve the corrosion resistance and aesthetic appeal of your aluminum extrusion.

- Add Accessories: Consider adding shelves, drawers, or other accessories to increase the utility of your design.

- Cable Management: If your structure will house electrical components, plan for cable management to keep everything organized and safe.

Step 6: Testing and Adjustments

Once your structure is complete, it's crucial to test it to ensure it meets your requirements. Check for stability, weight capacity, and functionality. If any adjustments are needed, the modular nature of aluminum extrusion allows for easy modifications.

Applications of 80 x 20 Aluminum Extrusion

The versatility of 80 x 20 aluminum extrusion makes it suitable for a wide range of applications, including:

- Workstations: Create custom workstations for manufacturing, assembly, or laboratory environments.

- Machine Frames: Build robust frames for machinery that require precise alignment and stability.

- Display Stands: Design attractive display stands for retail or trade shows.

- Automated Systems: Construct frames for automated systems, including robotics and conveyor systems.

- Furniture: Create modern furniture pieces, such as desks, tables, and shelving units.

Advanced Customization Techniques

Integrating Technology

Incorporating technology into your design can significantly enhance its functionality. For instance, you can integrate sensors, motors, or lighting systems into your aluminum extrusion framework. This is particularly useful in automated systems where real-time data collection and response are crucial.

Using CAD for Prototyping

Utilizing CAD software not only helps in designing but also in prototyping. You can simulate the performance of your design under various conditions, allowing you to make necessary adjustments before physical assembly. This can save time and resources, ensuring that your final product meets all specifications.

Collaborative Design

If you are working on a larger project, consider using collaborative design tools that allow multiple users to contribute to the design process. This can lead to more innovative solutions and a more refined final product. Platforms that support real-time collaboration can help teams work together efficiently, regardless of their physical location.

Sustainability Considerations

When customizing your design, consider the environmental impact of your materials and processes. Aluminum is a recyclable material, and using it in your projects can contribute to sustainability efforts. Additionally, consider designing for disassembly, which allows for easier recycling at the end of the product's life cycle.

Conclusion

Customizing your design with 80 x 20 aluminum extrusion opens up a world of possibilities. Its versatility, ease of assembly, and aesthetic appeal make it an excellent choice for various applications. By following the steps outlined in this article, you can create a structure that meets your specific needs while enjoying the benefits of aluminum extrusion.

Frequently Asked Questions

1. What tools do I need to work with 80 x 20 aluminum extrusion?

Basic tools include a saw for cutting, a drill for making holes, and a wrench for tightening fasteners. A torque wrench is also recommended for precise assembly.

2. Can I use 80 x 20 aluminum extrusion for outdoor projects?

Yes, aluminum is naturally resistant to corrosion, making it suitable for outdoor use. However, consider applying a protective finish for added durability.

3. How do I ensure my structure is stable?

Ensure that your design accounts for weight distribution and that all connections are secure. Periodically check for squareness during assembly.

4. Is it possible to modify my design after assembly?

Yes, one of the key benefits of aluminum extrusion is its modularity. You can easily add or remove components as needed.

5. Where can I find 80 x 20 aluminum extrusion components?

Many suppliers offer 80 x 20 aluminum extrusion and related components online. Check local hardware stores or specialized suppliers for availability.