Content Menu

● Understanding 80-20 Aluminum Extrusion

>> Key Features of 80-20 Aluminum Extrusion

● Customizing Your Design

>> Step 1: Define Your Project Requirements

>> Step 2: Choose the Right Profiles

>> Step 3: Utilize CAD Software for Design

>> Step 4: Assemble Your Components

>> Step 5: Finishing Touches

● Applications of 80-20 Aluminum Extrusion

● Benefits of Using 80-20 Aluminum Extrusion

● Advanced Customization Techniques

>> Integrating Electronics

>> Modular Design for Future Expansion

>> Custom Machining Services

>> Utilizing 3D Printing

● Conclusion

● Frequently Asked Questions

>> 1. What tools do I need to work with 80-20 aluminum extrusion?

>> 2. Can I use 80-20 aluminum extrusion outdoors?

>> 3. How do I determine the load capacity of my aluminum extrusion design?

>> 4. Is it possible to modify an existing 80-20 structure?

>> 5. Where can I find resources for designing with 80-20 aluminum extrusion?

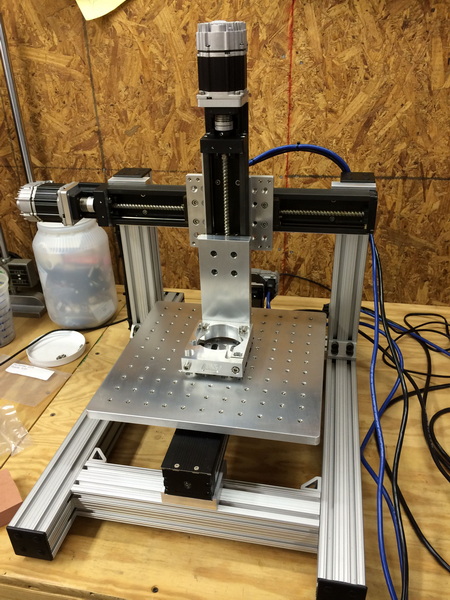

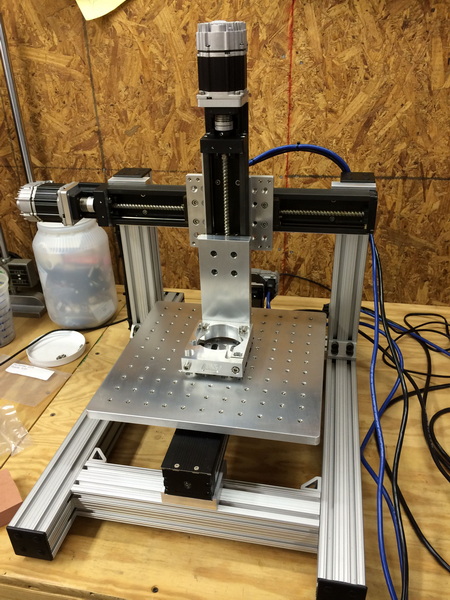

80-20 aluminum extrusion is a versatile and innovative solution for a wide range of applications, from industrial machinery to DIY projects. The unique T-slot design of 80-20 aluminum extrusions allows for easy customization and assembly, making it an ideal choice for engineers, designers, and hobbyists alike. In this article, we will explore how you can customize your design using 80-20 aluminum extrusion, the benefits of using this material, and practical tips for getting started.

Understanding 80-20 Aluminum Extrusion

80-20 aluminum extrusion refers to a specific type of aluminum framing system that utilizes a T-slot design. This design allows for the easy attachment of various components, making it highly adaptable for different projects. The name "80-20" comes from the fact that the extrusions are typically 80mm wide and 20mm tall, although there are many other sizes and profiles available.

Key Features of 80-20 Aluminum Extrusion

1. T-Slot Design: The T-slot design allows for easy assembly and disassembly. Components can be added or removed without the need for specialized tools, making it perfect for prototyping and iterative design processes.

2. Lightweight and Strong: Aluminum is known for its strength-to-weight ratio. 80-20 aluminum extrusions are lightweight yet robust, making them suitable for both structural and aesthetic applications.

3. Corrosion Resistance: Aluminum naturally resists corrosion, which makes it ideal for use in various environments, including those exposed to moisture or chemicals.

4. Modular System: The modular nature of 80-20 aluminum extrusion means that you can create complex structures by combining different profiles and components. This flexibility is particularly useful in custom applications.

Customizing Your Design

Step 1: Define Your Project Requirements

Before diving into the design process, it's essential to clearly define your project requirements. Consider the following questions:

- What is the purpose of your design?

- What dimensions do you need?

- Will the structure need to support any weight?

- Are there specific environmental conditions to consider (e.g., moisture, temperature)?

Step 2: Choose the Right Profiles

80-20 aluminum extrusions come in various profiles, each suited for different applications. Common profiles include:

- Standard T-Slot Profiles: These are the most versatile and can be used for a wide range of applications.

- Angled Profiles: Ideal for creating corners or angled structures.

- Panel Mount Profiles: Used for attaching panels or other flat surfaces.

- Bearing Profiles: Designed for applications requiring rotational movement.

Selecting the right profile is crucial for ensuring that your design meets its intended purpose.

Step 3: Utilize CAD Software for Design

Using computer-aided design (CAD) software can significantly enhance your design process. Many CAD programs allow you to create 3D models of your structure, enabling you to visualize how different components will fit together. Some popular CAD software options include:

- SolidWorks

- AutoCAD

- Fusion 360

- SketchUp

These tools often have libraries of 80-20 aluminum profiles, making it easier to incorporate them into your designs.

Step 4: Assemble Your Components

Once you have your design finalized, it's time to assemble your components. The assembly process is straightforward due to the T-slot design. Here are some tips for a successful assembly:

- Use the Right Fasteners: Ensure you have the appropriate fasteners for your profiles. 80-20 offers a variety of fasteners, including T-nuts, bolts, and brackets.

- Follow Your Design: Refer to your CAD model or assembly instructions to ensure that you are assembling the structure correctly.

- Check for Squareness: As you assemble, regularly check that your structure is square. This will help ensure stability and proper alignment.

Step 5: Finishing Touches

After assembling your structure, consider adding finishing touches to enhance its functionality and appearance. This could include:

- Adding Panels: Use panels to enclose your structure or create surfaces for work.

- Incorporating Accessories: 80-20 offers a range of accessories, such as wheels, handles, and brackets, to enhance your design.

- Surface Treatments: Depending on your application, you may want to apply surface treatments to improve aesthetics or durability.

Applications of 80-20 Aluminum Extrusion

The versatility of 80-20 aluminum extrusion means it can be used in a wide range of applications, including:

- Workstations: Create custom workstations tailored to specific tasks or workflows.

- Machine Guards: Design safety enclosures for machinery to protect operators.

- Display Stands: Build attractive display stands for retail or exhibitions.

- Automated Systems: Use aluminum extrusions to create frames for automated systems and robotics.

Benefits of Using 80-20 Aluminum Extrusion

1. Cost-Effective: The modular nature of 80-20 aluminum extrusion can reduce costs associated with custom fabrication.

2. Time-Saving: Quick assembly and disassembly allow for rapid prototyping and adjustments.

3. Sustainability: Aluminum is a recyclable material, making it an environmentally friendly choice.

4. Aesthetic Appeal: The clean lines and modern look of aluminum extrusion can enhance the visual appeal of your projects.

Advanced Customization Techniques

Integrating Electronics

For projects that require electronic components, 80-20 aluminum extrusion can be easily integrated with wiring and electronic devices. You can design enclosures that not only house the electronics but also provide cooling solutions through ventilation. This is particularly useful in applications like robotics or automated systems where heat dissipation is critical.

Modular Design for Future Expansion

One of the significant advantages of using 80-20 aluminum extrusion is the ability to design modular systems. This means you can create a base structure that can be expanded or modified in the future. For instance, if you are building a workstation, you can design it in such a way that additional components can be added later without needing to start from scratch.

Custom Machining Services

If your project requires specific dimensions or features that standard profiles do not provide, many suppliers offer custom machining services. This allows you to have profiles cut to your exact specifications, ensuring a perfect fit for your design. Custom machining can include drilling holes, adding slots, or even creating unique shapes.

Utilizing 3D Printing

In conjunction with 80-20 aluminum extrusion, 3D printing can be used to create custom connectors or components that may not be readily available. This hybrid approach allows for even greater customization and can help in creating unique solutions tailored to specific needs.

Conclusion

Customizing your design with 80-20 aluminum extrusion opens up a world of possibilities for creating functional and aesthetically pleasing structures. By understanding the features of 80-20, defining your project requirements, and utilizing CAD software, you can effectively design and assemble a wide range of applications. Whether you are an engineer, designer, or hobbyist, 80-20 aluminum extrusion provides the flexibility and strength needed to bring your ideas to life.

Frequently Asked Questions

1. What tools do I need to work with 80-20 aluminum extrusion?

Basic tools include a saw for cutting aluminum, a drill for making holes, and standard hand tools for assembly, such as wrenches and screwdrivers.

2. Can I use 80-20 aluminum extrusion outdoors?

Yes, aluminum is naturally resistant to corrosion, making it suitable for outdoor applications. However, consider using additional protective coatings for extended exposure to harsh environments.

3. How do I determine the load capacity of my aluminum extrusion design?

Load capacity can be calculated based on the profile size, the type of load (static or dynamic), and the configuration of the structure. It's advisable to consult manufacturer guidelines for specific load ratings.

4. Is it possible to modify an existing 80-20 structure?

Yes, one of the key benefits of 80-20 aluminum extrusion is its modularity, allowing for easy modifications and upgrades to existing structures.

5. Where can I find resources for designing with 80-20 aluminum extrusion?

Many manufacturers provide design resources, including CAD libraries, assembly instructions, and project ideas on their websites.