Content Menu

● Understanding Aluminum Extrusion

● Benefits of Using 45mm Aluminum Extrusion

● Customization Techniques

>> Cutting and Machining

>> Joining Techniques

>> Finishing Options

>> Incorporating Accessories

● Applications of 45mm Aluminum Extrusion

>> Industrial Machinery

>> Furniture Design

>> Display Systems

>> Automotive Applications

>> Architectural Features

● Design Considerations

>> Load Requirements

>> Environmental Factors

>> Aesthetic Preferences

>> Assembly and Disassembly Needs

● Conclusion

● Frequently Asked Questions

>> 1. What is the maximum load capacity of 45mm aluminum extrusion?

>> 2. Can I cut aluminum extrusion at home?

>> 3. What finishing options are available for aluminum extrusions?

>> 4. How do I join aluminum extrusions together?

>> 5. Is aluminum extrusion environmentally friendly?

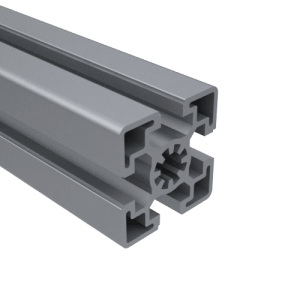

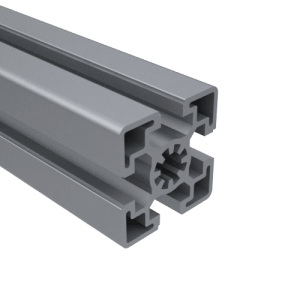

Aluminum extrusion is a versatile manufacturing process that allows for the creation of complex shapes and profiles from aluminum. Among the various sizes available, the 45mm aluminum extrusion is particularly popular due to its balance of strength, weight, and adaptability. This article explores how you can customize 45mm aluminum extrusion to meet unique design needs, covering various aspects such as design considerations, customization techniques, applications, and more.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum through a die to create a specific cross-sectional shape. This process allows for the production of long lengths of aluminum profiles that can be cut to size for various applications. The 45mm aluminum extrusion is characterized by its square shape, which provides excellent structural integrity and is ideal for a wide range of applications, from industrial machinery to furniture design.

Benefits of Using 45mm Aluminum Extrusion

1. Strength and Durability: Aluminum is known for its strength-to-weight ratio, making it an excellent choice for structural applications. The 45mm profile can support significant loads while remaining lightweight.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion. This property is particularly beneficial for outdoor applications or environments with high humidity.

3. Versatility: The 45mm extrusion can be used in various applications, including framing, supports, and enclosures. Its modular nature allows for easy assembly and disassembly.

4. Aesthetic Appeal: Aluminum can be finished in various ways, including anodizing and powder coating, allowing for customization in appearance to match design aesthetics.

Customization Techniques

Customizing 45mm aluminum extrusion involves several techniques that can enhance its functionality and appearance. Here are some common methods:

Cutting and Machining

One of the simplest ways to customize aluminum extrusion is through cutting and machining. This can include:

- Length Adjustment: Extrusions can be cut to specific lengths to fit particular applications.

- Drilling Holes: Adding holes for fasteners or other components can be done using standard drilling techniques.

- Milling: More complex shapes can be created through milling, allowing for intricate designs and features.

Joining Techniques

Joining different pieces of aluminum extrusion can create larger structures. Common methods include:

- T-Slot Connectors: These connectors allow for easy assembly and disassembly of frames and structures.

- Welding: For permanent connections, welding can be used to join aluminum pieces together.

- Adhesives: Specialized adhesives can bond aluminum extrusions without the need for mechanical fasteners.

Finishing Options

Finishing techniques can enhance the appearance and durability of aluminum extrusions. Some popular options include:

- Anodizing: This electrochemical process increases corrosion resistance and allows for color customization.

- Powder Coating: A dry finishing process that provides a durable and attractive finish in various colors.

- Brushing and Polishing: These techniques can create a sleek, modern look for aluminum surfaces.

Incorporating Accessories

To enhance functionality, various accessories can be integrated into the design of 45mm aluminum extrusions:

- End Caps: These can provide a finished look and protect the ends of the extrusion.

- Corner Brackets: Useful for creating right angles in frames and structures.

- Mounting Plates: These can be attached to extrusions to facilitate the mounting of other components.

Applications of 45mm Aluminum Extrusion

The versatility of 45mm aluminum extrusion makes it suitable for a wide range of applications, including:

Industrial Machinery

In industrial settings, 45mm aluminum extrusions are often used to create frames for machinery, conveyor systems, and workstations. Their strength and lightweight nature make them ideal for these applications.

Furniture Design

Aluminum extrusions can be used in furniture design, providing a modern aesthetic and durable structure. They can be customized to create tables, chairs, and shelving units.

Display Systems

Retail environments often use aluminum extrusions for display systems. The ability to customize the height, width, and configuration allows for unique and eye-catching displays.

Automotive Applications

In the automotive industry, aluminum extrusions are used for various components, including frames and supports. Their lightweight nature contributes to fuel efficiency.

Architectural Features

Aluminum extrusions can be used in architectural applications, such as window frames, curtain walls, and structural supports. Their aesthetic appeal and durability make them a popular choice in modern architecture.

Design Considerations

When customizing 45mm aluminum extrusion, several design considerations should be taken into account:

Load Requirements

Understanding the load requirements of your application is crucial. The 45mm extrusion can support significant weight, but it's essential to calculate the load to ensure safety and stability.

Environmental Factors

Consider the environment in which the aluminum extrusion will be used. If it will be exposed to moisture or chemicals, selecting the appropriate finishing technique is vital to prevent corrosion.

Aesthetic Preferences

The appearance of the aluminum extrusion can significantly impact the overall design. Choose finishes and colors that align with your design vision.

Assembly and Disassembly Needs

If the structure needs to be assembled and disassembled frequently, consider using T-slot connectors and other modular components that facilitate easy reconfiguration.

Conclusion

Customizing 45mm aluminum extrusion offers endless possibilities for creating unique designs tailored to specific needs. By understanding the various customization techniques, applications, and design considerations, you can leverage the benefits of aluminum extrusion to enhance your projects. Whether for industrial, architectural, or personal use, 45mm aluminum extrusion provides a robust and versatile solution.

Frequently Asked Questions

1. What is the maximum load capacity of 45mm aluminum extrusion?

The load capacity depends on the specific design and configuration, but 45mm aluminum extrusions are known for their high strength-to-weight ratio, making them suitable for heavy-duty applications.

2. Can I cut aluminum extrusion at home?

Yes, aluminum extrusion can be cut at home using standard tools like a miter saw or a band saw, provided you take the necessary safety precautions.

3. What finishing options are available for aluminum extrusions?

Common finishing options include anodizing, powder coating, and brushing or polishing, each providing different aesthetic and protective qualities.

4. How do I join aluminum extrusions together?

Aluminum extrusions can be joined using T-slot connectors, welding, or adhesives, depending on the desired strength and permanence of the connection.

5. Is aluminum extrusion environmentally friendly?

Yes, aluminum is recyclable, and the extrusion process can be designed to minimize waste, making it a more sustainable choice compared to other materials.