Content Menu

● Understanding Slice and Extrusion Production

● Benefits of Slice and Extrusion Production

● How Slice and Extrusion Improve Product Quality

>> Enhanced Texture and Flavor

>> Nutrient Retention

>> Customization Opportunities

● Applications in Various Industries

>> Food Industry

>> Plastics Industry

● Innovations in Slice and Extrusion Technology

>> Automation in Slicing

>> Advanced Extrusion Techniques

● Challenges in Slice and Extrusion Production

>> Equipment Maintenance

>> Material Selection

● Conclusion

● FAQ

>> 1. What are the main advantages of extrusion in food processing?

>> 2. How does slicing improve food presentation?

>> 3. Can extrusion be used for both food and non-food products?

>> 4. What types of products can be made using extrusion?

>> 5. How does extrusion affect nutrient retention in food?

● Citations:

The processes of slice and extrusion production have revolutionized various manufacturing industries, particularly in food and plastics. These techniques not only improve efficiency but also enhance the quality of the final products. This article explores the intricacies of slice and extrusion production, examining how they contribute to superior product quality across different sectors.

Understanding Slice and Extrusion Production

What is Extrusion?

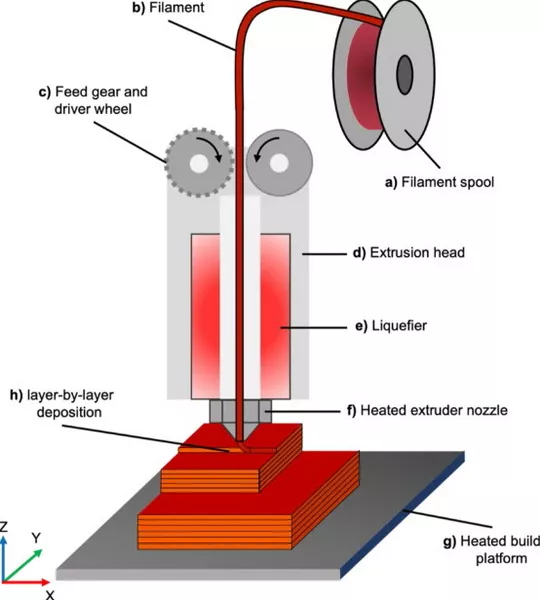

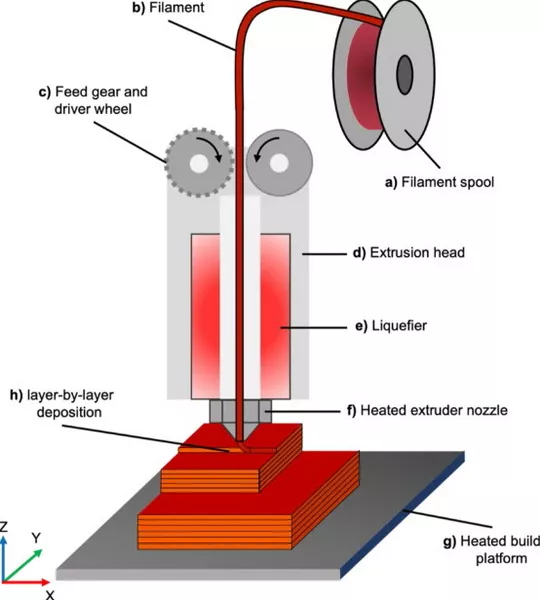

Extrusion is a manufacturing process that involves forcing material through a specific-shaped die under controlled temperature and pressure conditions. This method is widely used in the production of various food items, plastics, and metals. The versatility of extrusion allows for the creation of a vast range of products, from snack foods to plastic pipes.

- Process Overview:

- Ingredient Preparation: Raw materials are selected and preconditioned.

- Feeding: The mixture is fed into an extruder.

- Cooking and Shaping: The material is cooked and shaped as it moves through the extruder.

- Die Shaping: The cooked mixture is forced through a die to create the desired shape.

- Cutting and Cooling: The extruded product is cut to length and cooled.

What is Slicing?

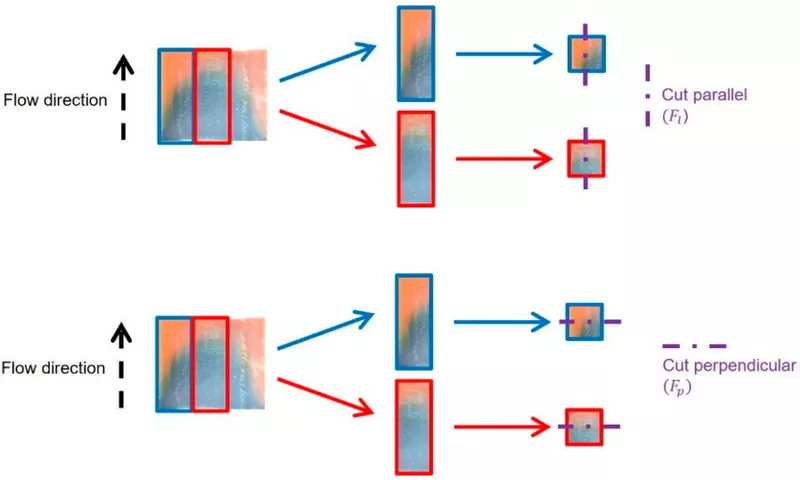

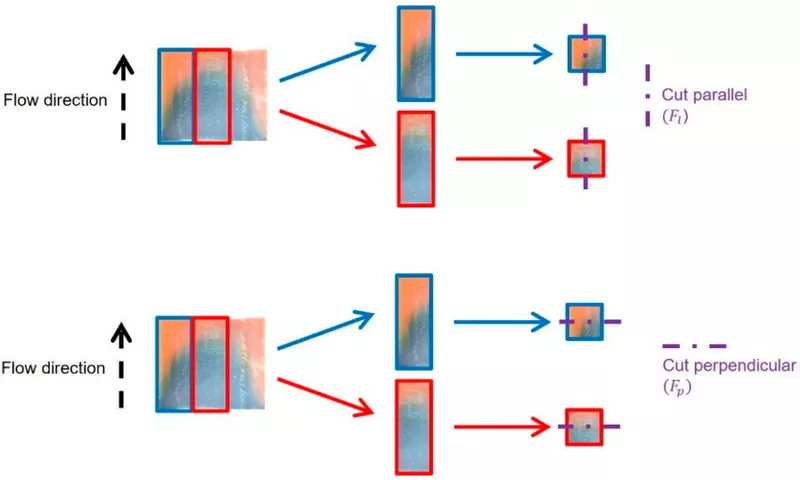

Slicing, on the other hand, refers to the process of cutting materials into specific shapes or sizes. In food production, slicing is often used to create uniform portions of products such as cheese, meats, or vegetables.

- Process Overview:

- Preparation: The product is prepared for slicing.

- Slicing: The product is cut into desired shapes using specialized equipment.

- Packaging: Sliced products are often packaged for distribution.

Benefits of Slice and Extrusion Production

The combination of slice and extrusion processes offers numerous benefits that significantly enhance product quality:

- Consistency in Quality: Both processes ensure uniformity in product size and shape, which is crucial for consumer satisfaction. For instance, extruded snacks maintain consistent texture and flavor profiles.

- Nutritional Enhancement: Extrusion allows for the incorporation of nutritional additives during processing. This capability enables manufacturers to enhance the health benefits of their products without compromising taste or texture.

- Reduced Waste: The precise control over materials in extrusion minimizes waste during production. This efficiency not only lowers costs but also contributes to more sustainable manufacturing practices.

- Versatility in Product Development: Manufacturers can easily switch between different product types using the same equipment, facilitating innovation and responsiveness to market demands.

How Slice and Extrusion Improve Product Quality

The enhancement of product quality through slice and extrusion production can be attributed to several key factors:

Enhanced Texture and Flavor

The extrusion process alters the physical properties of food products, improving their texture and flavor. For example:

- Snack Foods: Extruded snacks often exhibit a light, crispy texture that appeals to consumers. The cooking process during extrusion gelatinizes starches, enhancing flavor release upon consumption.

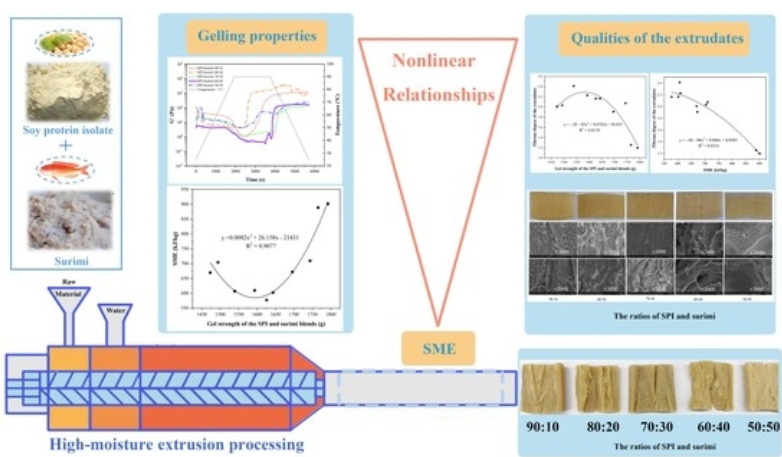

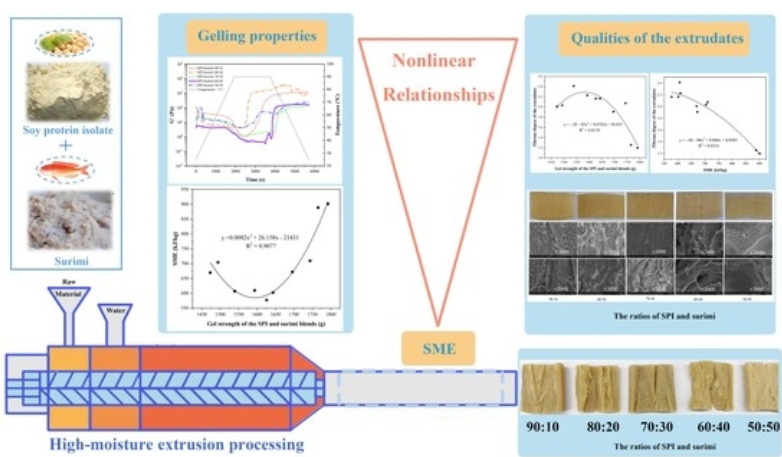

- Meat Analogues: In plant-based meat alternatives, extrusion technology mimics the fibrous structure of meat, providing a more satisfying mouthfeel.

Nutrient Retention

Extrusion can help preserve essential nutrients during processing:

- Controlled Processing Conditions: By managing temperature and pressure during extrusion, manufacturers can retain vitamins and minerals that might otherwise degrade during traditional cooking methods.

- Bioavailability Enhancement: The mechanical action involved in extrusion can improve the bioavailability of certain nutrients, making them more accessible for absorption by the body.

Customization Opportunities

Both slicing and extrusion offer customization capabilities that enhance product appeal:

- Tailored Shapes: Extrusion allows for unique shapes that can attract consumers' attention. For instance, pasta can be extruded into various forms that are visually appealing.

- Flavor Infusions: Slicing enables manufacturers to create layered products with distinct flavors or textures. For example, cheese slices can be combined with herbs or spices for added taste.

Applications in Various Industries

The applications of slice and extrusion production span multiple industries:

Food Industry

- Snack Foods: Extruded snacks such as puffed rice or corn chips benefit from enhanced texture and flavor retention.

- Breakfast Cereals: Extrusion technology allows for the production of cereals with varied shapes and textures while preserving nutritional content.

- Meat Alternatives: With the rise of plant-based diets, extrusion technology plays a vital role in creating meat substitutes that mimic the texture and taste of real meat.

Plastics Industry

- Packaging Materials: Extruded plastic films are used in packaging applications due to their consistency and durability.

- Construction Materials: Plastic pipes produced through extrusion offer uniformity in dimensions, ensuring reliable performance in construction projects.

Innovations in Slice and Extrusion Technology

Recent advancements in slice and extrusion technology have further enhanced product quality:

Automation in Slicing

Modern slicing machines now incorporate automation features that increase efficiency while maintaining precision. For instance:

- Slice-and-Apply Technology: This innovation allows food processors to slice products directly onto bases like pizzas or sandwiches without additional handling steps. This not only speeds up production but also reduces labor costs while improving consistency[4].

Advanced Extrusion Techniques

Advancements in extrusion technology include:

- Computer-Controlled Systems: These systems optimize material distribution and shape formation, reducing variability while improving product quality[12].

- In-Line Processing Enhancements: Integrating additional processing steps within the extrusion line (such as cooling or coating) has streamlined operations by minimizing material handling[12].

Challenges in Slice and Extrusion Production

Despite their advantages, slice and extrusion processes face challenges that must be addressed to maintain high-quality outputs:

Equipment Maintenance

Regular maintenance of slicing machines and extruders is critical to ensure consistent performance. Wear on blades or dies can lead to defects in product quality[10].

Material Selection

Choosing appropriate materials for both slicing and extrusion is essential. Factors such as melting point, viscosity, and compatibility with processing conditions must be considered[5].

Conclusion

In conclusion, slice and extrusion production significantly enhance product quality across various sectors by ensuring consistency, improving nutritional content, reducing waste, and allowing for customization. As industries continue to evolve towards sustainability and consumer-centric products, these manufacturing techniques will play a crucial role in meeting market demands while maintaining high standards of quality.

FAQ

1. What are the main advantages of extrusion in food processing?

Extrusion offers advantages such as improved texture, enhanced flavor retention, reduced waste, and the ability to incorporate nutritional additives during processing.

2. How does slicing improve food presentation?

Slicing creates uniform portions that enhance visual appeal and make it easier for consumers to use products in meal preparation or consumption.

3. Can extrusion be used for both food and non-food products?

Yes, extrusion technology is versatile enough to be applied in both food processing (e.g., snacks) and non-food industries (e.g., plastic pipes).

4. What types of products can be made using extrusion?

Extrusion can produce a wide range of products including snack foods, breakfast cereals, pasta, pet food, plastic films, pipes, and profiles.

5. How does extrusion affect nutrient retention in food?

Extrusion can help preserve essential nutrients by controlling processing conditions such as temperature and pressure during cooking.

Citations:

[1] https://blog.triangular-pod.com/why-is-extrusion-such-a-versatile-process/

[2] https://www.tensilemillcnc.com/blog/the-most-efficient-aluminum-extrusion-process-with-precise-quality-control-will-guarantee-the-best-results-of-your-production

[3] https://www.snackandbakery.com/articles/99779-producers-seek-to-extrude-better-for-you-fun-ingredients

[4] https://www.grotecompany.com/en-us/resource/Article/410/Slice-Apply-Streamlining-Food-Processing

[5] https://giftsafetyservices.com/understanding-the-extrusion-process-in-manufacturing/

[6] https://www.inplexllc.com/blog/2023-plastic-extrusion-trends/

[7] https://paulmurphyplastics.com/industry-news-blog/extrusion-process-working-types-application-advantages-and-disadvantages/

[8] https://www.linkedin.com/advice/0/how-can-extrusion-technology-improve-your-food-5q22e

[9] https://pmc.ncbi.nlm.nih.gov/articles/PMC5954828/

[10] https://plasticextrusiontech.net/from-equipment-to-processing-factors-that-make-or-break-plastic-extrusion-quality/

[11] https://leverwood.com/benefits-and-applications-of-blades/

[12] https://www.seagateplastics.com/shaping-the-future-innovations-in-plastic-extrusion-techniques/

[13] https://hunterplastics.com/trends-in-plastic-extrusion-technology

[14] https://www.cowellextrusion.com/everything-you-need-to-know-about-sheet-extrusion-a-comprehensive-guide/

[15] https://www.wevolver.com/article/extruding-plastic

[16] https://www.tetrapak.com/en-us/about-tetra-pak/news-and-events/newsarchive/medium-capacity-extrusion-line

[17] https://aec.org/extrusion-die-process-application

[18] https://www.mpo-mag.com/extrusion-evolution-290795/