Content Menu

● Introduction to Plastics Extrusion Machinery LLC in Tumwater

● Understanding Plastics Extrusion: The Basics

>> Key Steps in the Extrusion Process

● Why Choose Plastics Extrusion Machinery LLC in Tumwater?

>> 1. Proven Track Record

>> 2. Cutting-Edge Technology

>> 3. Comprehensive Solutions

>> 4. Customization

>> 5. Exceptional Customer Support

● Key Offerings and Services

>> 1. Extruders

>> 2. Downstream Equipment

>> 3. Custom Dies and Tooling

>> 4. Automation Solutions

>> 5. Retrofits and Upgrades

● How Their Technology Improves Your Production Line

>> 1. Increased Throughput

>> 2. Enhanced Product Quality

>> 3. Energy Efficiency

>> 4. Reduced Downtime

>> 5. Flexibility

● Customization and Flexibility

>> Customization Options Include:

● After-Sales Support and Training

>> Support Services Include:

● Sustainability and Environmental Responsibility

>> Key Initiatives:

● Case Studies: Real-World Success Stories

>> Case Study 1: Boosting Output for a Pipe Manufacturer

>> Case Study 2: Custom Profile Production for a Start-Up

>> Case Study 3: Retrofitting for Sustainability

● Future Trends and Innovations

>> 1. Smart Manufacturing

>> 2. Advanced Materials

>> 3. Automation and Robotics

>> 4. Sustainable Manufacturing

● Conclusion

● FAQ

>> 1. What types of plastics can be processed with machinery from Plastics Extrusion Machinery LLC in Tumwater?

>> 2. Can Plastics Extrusion Machinery LLC in Tumwater retrofit existing production lines?

>> 3. How does the company support customers after installation?

>> 4. What customization options are available for extrusion machinery?

>> 5. How does Plastics Extrusion Machinery LLC in Tumwater address sustainability?

In today's fast-paced manufacturing environment, the efficiency and quality of your production line can make or break your business. For companies operating in the plastics industry, the right extrusion machinery is the backbone of successful operations. Plastics Extrusion Machinery LLC in Tumwater stands out as a leading provider of advanced extrusion solutions, helping manufacturers optimize their production lines, increase output, and ensure product consistency. In this comprehensive article, we will explore how Plastics Extrusion Machinery LLC in Tumwater can revolutionize your production process, the unique advantages they offer, and why they are the partner of choice for businesses seeking to stay ahead in the competitive plastics market.

Introduction to Plastics Extrusion Machinery LLC in Tumwater

Plastics Extrusion Machinery LLC in Tumwater is a renowned manufacturer and supplier of high-performance extrusion equipment. Located in Tumwater, Washington, the company has built a solid reputation for delivering state-of-the-art machinery and comprehensive solutions tailored to the needs of plastics manufacturers. Their commitment to quality, innovation, and customer satisfaction has made them a preferred partner for businesses of all sizes.

The company's mission is clear: to empower manufacturers with reliable, efficient, and technologically advanced extrusion machinery that enhances productivity and ensures long-term success. Whether you are a start-up or an established enterprise, Plastics Extrusion Machinery LLC in Tumwater offers the expertise and resources to elevate your production capabilities.

Understanding Plastics Extrusion: The Basics

Before diving into the specific ways Plastics Extrusion Machinery LLC in Tumwater can benefit your business, it's essential to understand the basics of plastics extrusion. Extrusion is a manufacturing process used to create objects of a fixed cross-sectional profile by pushing molten plastic through a die. This process is widely used for producing pipes, tubing, sheets, films, and various custom profiles.

Key Steps in the Extrusion Process

1. Feeding: Raw plastic material (usually in the form of pellets) is fed into the extruder.

2. Melting: The material is heated and melted as it moves through the barrel.

3. Mixing: The molten plastic is mixed to ensure uniformity.

4. Shaping: The material is forced through a die, forming the desired shape.

5. Cooling: The shaped plastic is cooled and solidified.

6. Cutting: The final product is cut to the required length or size.

The quality, efficiency, and consistency of this process depend heavily on the machinery used. This is where Plastics Extrusion Machinery LLC in Tumwater excels.

Why Choose Plastics Extrusion Machinery LLC in Tumwater?

Selecting the right machinery supplier is a critical decision for any manufacturer. Here are several reasons why Plastics Extrusion Machinery LLC in Tumwater is a top choice:

1. Proven Track Record

With decades of experience, the company has a deep understanding of the challenges faced by plastics manufacturers. Their solutions are backed by a history of successful implementations across diverse industries.

2. Cutting-Edge Technology

Plastics Extrusion Machinery LLC in Tumwater invests heavily in research and development, ensuring their equipment incorporates the latest technological advancements. This translates into higher efficiency, better product quality, and reduced operational costs.

3. Comprehensive Solutions

From initial consultation to installation, training, and ongoing support, the company offers end-to-end solutions. This holistic approach ensures seamless integration with your production line.

4. Customization

No two manufacturing operations are the same. Plastics Extrusion Machinery LLC in Tumwater specializes in designing and building custom machinery tailored to the specific needs of each client.

5. Exceptional Customer Support

Their commitment to customer satisfaction extends beyond the sale. With responsive support teams and extensive training programs, they ensure your team can operate the machinery at peak performance.

Key Offerings and Services

Plastics Extrusion Machinery LLC in Tumwater provides a wide range of products and services designed to meet the diverse needs of plastics manufacturers.

1. Extruders

The heart of any extrusion line, their extruders are engineered for maximum efficiency and durability. Available in various sizes and configurations, these machines can handle a wide range of materials and applications.

2. Downstream Equipment

From cooling tanks and haul-offs to cutters and winders, the company offers all the necessary downstream equipment to complete your production line.

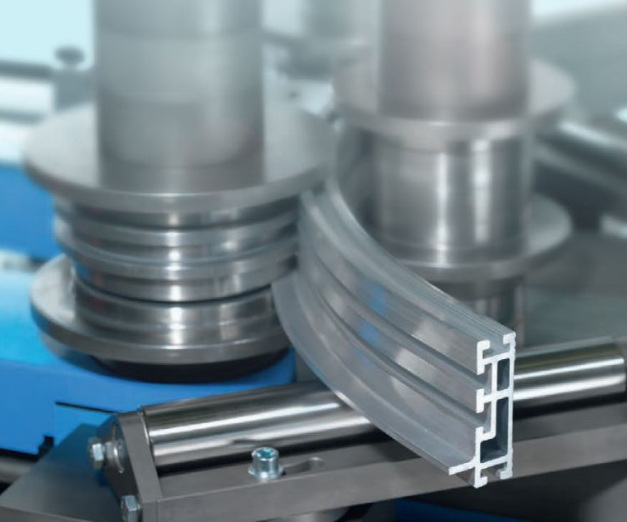

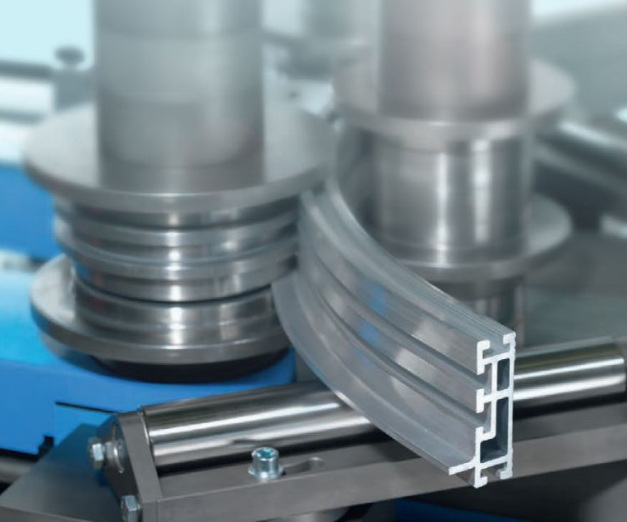

3. Custom Dies and Tooling

Precision dies and tooling are essential for producing high-quality extruded products. Plastics Extrusion Machinery LLC in Tumwater designs and manufactures custom dies to meet exact specifications.

4. Automation Solutions

To maximize productivity and minimize labor costs, the company offers advanced automation solutions, including process monitoring, control systems, and robotics.

5. Retrofits and Upgrades

If you're not ready to invest in new machinery, Plastics Extrusion Machinery LLC in Tumwater can retrofit or upgrade your existing equipment, enhancing performance and extending its lifespan.

How Their Technology Improves Your Production Line

The impact of advanced extrusion machinery on your production line can be profound. Here's how Plastics Extrusion Machinery LLC in Tumwater helps manufacturers achieve superior results:

1. Increased Throughput

Modern extruders and downstream equipment are designed for high-speed operation without compromising quality. This means you can produce more in less time, boosting overall output.

2. Enhanced Product Quality

Precision engineering and advanced controls ensure consistent product dimensions, surface finish, and material properties. This reduces waste and minimizes the need for rework.

3. Energy Efficiency

Energy costs are a significant concern for manufacturers. The company's machinery incorporates energy-saving features, such as efficient heating systems and variable speed drives, reducing operational expenses.

4. Reduced Downtime

Reliability is built into every machine. With robust construction and intelligent diagnostics, unplanned downtime is minimized, keeping your production line running smoothly.

5. Flexibility

The ability to quickly change dies and adjust process parameters allows you to respond rapidly to market demands and produce a wide variety of products with minimal setup time.

Customization and Flexibility

One of the standout features of Plastics Extrusion Machinery LLC in Tumwater is their commitment to customization. Every manufacturing operation has unique requirements, and off-the-shelf solutions often fall short. The company works closely with clients to understand their specific needs and develop tailored solutions.

Customization Options Include:

- Material Compatibility: Machines can be optimized for different types of plastics, including PVC, HDPE, LDPE, and more.

- Product Dimensions: Custom dies and tooling allow for the production of products with unique shapes and sizes.

- Automation Level: From manual to fully automated lines, the company can design systems that match your desired level of automation.

- Integration: Machinery can be seamlessly integrated with existing equipment and production management systems.

This flexibility ensures that your investment delivers maximum value and positions your business for future growth.

After-Sales Support and Training

Investing in new machinery is only the beginning. To ensure long-term success, Plastics Extrusion Machinery LLC in Tumwater provides comprehensive after-sales support and training.

Support Services Include:

- Installation and Commissioning: Experienced technicians handle the installation and ensure everything is set up correctly.

- Operator Training: Hands-on training programs equip your staff with the skills needed to operate and maintain the equipment efficiently.

- Technical Support: A dedicated support team is available to troubleshoot issues and provide guidance, minimizing downtime.

- Spare Parts and Maintenance: The company maintains a robust inventory of spare parts and offers preventive maintenance services to keep your machinery in top condition.

This commitment to customer success sets Plastics Extrusion Machinery LLC in Tumwater apart from competitors.

Sustainability and Environmental Responsibility

Sustainability is a growing concern in the manufacturing sector. Plastics Extrusion Machinery LLC in Tumwater is committed to helping clients reduce their environmental footprint through innovative machinery and processes.

Key Initiatives:

- Energy-Efficient Designs: Equipment is engineered to consume less energy, reducing greenhouse gas emissions.

- Recycling Capabilities: Machinery can be configured to process recycled materials, supporting circular economy initiatives.

- Waste Reduction: Precision controls and automation minimize material waste during production.

By partnering with Plastics Extrusion Machinery LLC in Tumwater, manufacturers can meet regulatory requirements, appeal to environmentally conscious customers, and contribute to a more sustainable future.

Case Studies: Real-World Success Stories

To illustrate the tangible benefits of working with Plastics Extrusion Machinery LLC in Tumwater, let's look at a few real-world examples.

Case Study 1: Boosting Output for a Pipe Manufacturer

A regional pipe manufacturer was struggling with outdated equipment that limited their production capacity. After consulting with Plastics Extrusion Machinery LLC in Tumwater, they invested in a new extrusion line tailored to their needs. The result was a 40% increase in throughput, improved product consistency, and a significant reduction in energy costs.

Case Study 2: Custom Profile Production for a Start-Up

A start-up specializing in custom plastic profiles needed a flexible solution to handle a variety of shapes and materials. Plastics Extrusion Machinery LLC in Tumwater designed a modular extrusion system that allowed for rapid die changes and easy process adjustments. The company was able to bring new products to market quickly and efficiently.

Case Study 3: Retrofitting for Sustainability

An established manufacturer wanted to reduce their environmental impact without replacing their entire production line. Plastics Extrusion Machinery LLC in Tumwater retrofitted their existing equipment with energy-efficient components and upgraded controls. This resulted in a 25% reduction in energy consumption and a measurable decrease in waste.

Future Trends and Innovations

The plastics industry is constantly evolving, and Plastics Extrusion Machinery LLC in Tumwater is at the forefront of innovation. Here are some trends and technologies shaping the future of extrusion:

1. Smart Manufacturing

Integration of IoT devices and data analytics enables real-time monitoring and optimization of production lines, leading to higher efficiency and predictive maintenance.

2. Advanced Materials

The development of new polymers and composites requires machinery capable of handling diverse material properties. Plastics Extrusion Machinery LLC in Tumwater continually updates their equipment to accommodate these advancements.

3. Automation and Robotics

Greater automation reduces labor costs, improves safety, and ensures consistent product quality. The company's automation solutions are designed to keep clients competitive in a rapidly changing market.

4. Sustainable Manufacturing

As regulations tighten and consumer demand for eco-friendly products grows, machinery that supports recycling and waste reduction will become increasingly important.

Plastics Extrusion Machinery LLC in Tumwater is committed to staying ahead of these trends, ensuring their clients are well-positioned for the future.

Conclusion

In summary, Plastics Extrusion Machinery LLC in Tumwater offers a comprehensive suite of solutions to help manufacturers improve their production lines. From cutting-edge technology and customized machinery to exceptional support and a commitment to sustainability, the company is a trusted partner for businesses seeking to enhance efficiency, quality, and profitability.

By investing in advanced extrusion equipment from Plastics Extrusion Machinery LLC in Tumwater, you can achieve higher throughput, better product consistency, and lower operational costs—all while supporting environmentally responsible manufacturing practices. Whether you're upgrading existing equipment or building a new production line from scratch, their expertise and dedication to customer success ensure you get the most out of your investment.

FAQ

1. What types of plastics can be processed with machinery from Plastics Extrusion Machinery LLC in Tumwater?

Plastics Extrusion Machinery LLC in Tumwater designs equipment compatible with a wide range of materials, including PVC, HDPE, LDPE, PP, ABS, and various specialty polymers. Custom solutions are available to handle unique material requirements.

2. Can Plastics Extrusion Machinery LLC in Tumwater retrofit existing production lines?

Yes, the company offers retrofit and upgrade services for existing extrusion lines. This includes installing energy-efficient components, upgrading control systems, and integrating new automation features to enhance performance and extend equipment life.

3. How does the company support customers after installation?

After installation, Plastics Extrusion Machinery LLC in Tumwater provides comprehensive support, including operator training, technical assistance, preventive maintenance, and a reliable supply of spare parts. Their goal is to ensure long-term operational success for every client.

4. What customization options are available for extrusion machinery?

Customization options include material compatibility, product dimensions, automation levels, and integration with existing equipment. The company works closely with clients to develop solutions tailored to their specific production needs.

5. How does Plastics Extrusion Machinery LLC in Tumwater address sustainability?

The company prioritizes sustainability through energy-efficient designs, support for recycled materials, and waste reduction initiatives. Their machinery helps manufacturers reduce their environmental footprint and comply with regulatory requirements.