Content Menu

● Understanding Aluminum Extrusion 6063 Scrap

>> Key Characteristics of Aluminum Extrusion 6063 Scrap

● Preparing Aluminum Extrusion 6063 Scrap for Recycling

>> Sorting and Cleaning

>> Baling

● Recycling Process for Aluminum Extrusion 6063 Scrap

● Market Insights for Aluminum Extrusion 6063 Scrap

● Enhancing the Value Proposition

>> Establish Relationships with Recyclers

>> Invest in Quality Equipment

>> Promote Sustainability

● Additional Strategies for Maximizing Value

>> Understanding Scrap Grades

>> Timing Your Sales

>> Using Technology for Better Management

● Environmental Impact of Recycling Aluminum Extrusion 6063 Scrap

● Case Studies on Successful Recycling Practices

>> Case Study 1: Local Recycling Center Partnership

>> Case Study 2: Innovative Processing Techniques

● Conclusion

● FAQs

>> 1. What are the main applications of aluminum extrusion 6063?

>> 2. How do I prepare my aluminum extrusion 6063 scrap for recycling?

>> 3. What is the recycling process for aluminum extrusion 6063?

>> 4. How does market demand affect the price of aluminum extrusion 6063 scrap?

>> 5. What are some sustainability benefits of recycling aluminum extrusion 6063?

Aluminum extrusion 6063 scrap is an essential resource in the recycling industry, known for its excellent extrudability and aesthetic appeal. This alloy is widely used in architectural applications, such as window frames, door frames, and irrigation tubing. As a blog writer, understanding how to maximize the value of aluminum extrusion 6063 scrap can help you create informative content that resonates with your audience. This article will explore various strategies to enhance the value of this scrap material, including preparation techniques, market insights, and recycling processes.

Understanding Aluminum Extrusion 6063 Scrap

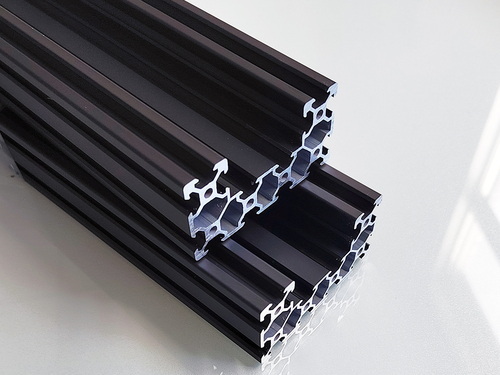

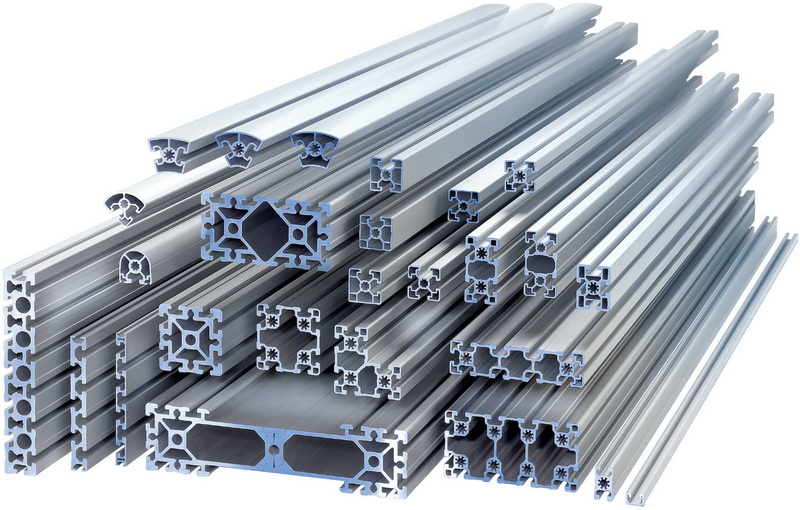

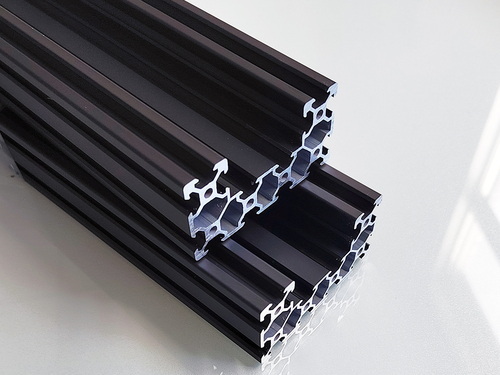

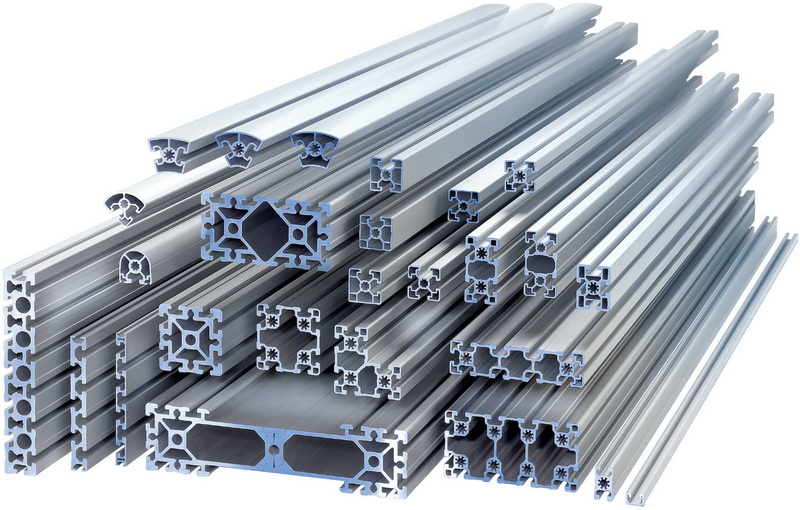

Aluminum extrusion 6063 scrap consists primarily of aluminum with magnesium and silicon as the main alloying elements. This composition provides 6063 with a balance of strength, corrosion resistance, and excellent surface finish. The scrap is typically derived from end-of-life architectural components and other commercial applications.

Key Characteristics of Aluminum Extrusion 6063 Scrap

- Excellent Extrudability: 6063 is known for its ability to be easily shaped into complex profiles.

- Aesthetic Finish: The alloy can be anodized or painted to achieve a high-quality appearance.

- Corrosion Resistance: It exhibits good resistance to corrosion, making it suitable for outdoor applications.

- Versatile Applications: Commonly used in architectural frames, furniture, electrical conduits, and more.

Preparing Aluminum Extrusion 6063 Scrap for Recycling

To maximize the value of aluminum extrusion 6063 scrap, proper preparation is crucial. Here are some effective techniques:

Sorting and Cleaning

1. Remove Contaminants: Ensure that the scrap is free from non-aluminum materials such as plastics, rubber, and iron components. Contaminated scrap can significantly reduce its value.

2. Sort by Grade: Different grades of aluminum scrap have varying market values. Sorting 6063 scrap from other alloys like 6061 can help you fetch a better price.

Baling

Baling involves compressing the aluminum scrap into dense blocks. This process not only reduces storage space but also makes transportation more efficient. Baled scrap is easier to handle during recycling operations and can lead to better pricing from recyclers.

Recycling Process for Aluminum Extrusion 6063 Scrap

Understanding the recycling process is essential for maximizing the value of aluminum extrusion 6063 scrap. Here's a step-by-step overview:

1. Shredding: The baled or large pieces of scrap are shredded into smaller sizes to facilitate melting.

2. Melting: The shredded aluminum is melted in furnaces. This process requires careful temperature control to avoid contamination.

3. Ingot Formation: Once melted, the aluminum is poured into molds to form ingots. These ingots can then be sold to manufacturers for producing new products.

4. Quality Control: Throughout the recycling process, it's essential to maintain quality control measures to ensure that the final product meets industry standards.

Market Insights for Aluminum Extrusion 6063 Scrap

To maximize value, staying informed about market trends is vital. Here are some key points:

- Demand Fluctuations: The demand for recycled aluminum varies based on economic conditions and industry needs. Keeping an eye on construction trends can provide insights into potential increases in demand for 6063 scrap.

- Pricing Trends: Regularly monitor scrap metal prices through online platforms or local recyclers to understand when to sell your scrap for maximum profit.

- Sustainability Practices: Many manufacturers are increasingly seeking sustainable materials. Highlighting the environmental benefits of using recycled aluminum can enhance its marketability.

Enhancing the Value Proposition

To further enhance the value of aluminum extrusion 6063 scrap, consider these strategies:

Establish Relationships with Recyclers

Building strong relationships with local recyclers can lead to better pricing and more favorable terms when selling your scrap. Regular communication can also keep you informed about market changes and opportunities.

Invest in Quality Equipment

Using high-quality equipment for processing and sorting your aluminum extrusion 6063 scrap can improve efficiency and reduce contamination risks.

Promote Sustainability

Emphasize the environmental benefits of recycling aluminum extrusion 6063 scrap in your marketing efforts. Highlighting reduced energy consumption and lower greenhouse gas emissions can attract eco-conscious buyers.

Additional Strategies for Maximizing Value

Understanding Scrap Grades

Different grades of aluminum extrusion scraps have different values based on their alloy composition and purity levels. For instance, clean aluminum extrusion 6063 will fetch a higher price than mixed or contaminated scraps. Familiarizing yourself with these grades can help you negotiate better prices when selling your materials.

Timing Your Sales

The price of aluminum extrusion 6063 scrap fluctuates based on market demand and supply dynamics. Keeping track of these fluctuations can help you sell at peak times when prices are higher. For example, sales tend to rise during construction booms or when new regulations favor recycled materials.

Using Technology for Better Management

Utilizing technology such as inventory management software can help track your aluminum extrusion 6063 scrap more efficiently. This software allows you to monitor quantities, grades, and market prices in real-time, enabling informed decision-making regarding sales timing and pricing strategies.

Environmental Impact of Recycling Aluminum Extrusion 6063 Scrap

Recycling aluminum extrusion 6063 has significant environmental benefits:

- Energy Savings: Recycling aluminum saves up to 95% of the energy required to produce new aluminum from bauxite ore. This reduction in energy consumption translates into lower greenhouse gas emissions.

- Reduced Landfill Waste: By recycling aluminum extrusion scraps instead of disposing of them in landfills, we contribute to waste reduction efforts that benefit the environment.

- Conservation of Natural Resources: Recycling helps conserve natural resources by reducing the need for mining raw materials, which can be environmentally damaging.

Case Studies on Successful Recycling Practices

To illustrate effective practices in maximizing the value of aluminum extrusion 6063 scrap, consider these examples:

Case Study 1: Local Recycling Center Partnership

A local recycling center partnered with construction firms to collect their aluminum extrusion scraps directly from job sites. By offering competitive pricing and convenient pickup services, they not only increased their supply but also built lasting relationships with contractors who regularly provided high-quality scraps.

Case Study 2: Innovative Processing Techniques

Another successful recycler invested in advanced shredding technology that minimized contamination during processing. This investment allowed them to produce higher purity grades of recycled aluminum, which commanded premium prices in the market due to their quality.

Conclusion

Maximizing the value of aluminum extrusion 6063 scrap involves understanding its characteristics, preparing it properly for recycling, staying informed about market trends, enhancing its value proposition through sustainable practices, and employing strategic partnerships and technology solutions. By implementing these strategies effectively, you can not only increase profitability but also contribute positively to environmental sustainability while providing valuable insights through your writing.

FAQs

1. What are the main applications of aluminum extrusion 6063?

Aluminum extrusion 6063 is commonly used in architectural applications such as window frames, door frames, irrigation tubing, electrical conduits, and furniture components due to its excellent extrudability and aesthetic finish.

2. How do I prepare my aluminum extrusion 6063 scrap for recycling?

To prepare your aluminum extrusion 6063 scrap for recycling, ensure it is clean and free from contaminants like plastics and iron components. Sort it by grade and consider baling it for efficient transportation.

3. What is the recycling process for aluminum extrusion 6063?

The recycling process involves shredding the scrap into smaller pieces, melting it in furnaces, forming ingots from the molten aluminum, and conducting quality control checks throughout the process to ensure high-quality output.

4. How does market demand affect the price of aluminum extrusion 6063 scrap?

Market demand affects pricing significantly; fluctuations in construction activity or changes in industrial needs can lead to variations in demand for recycled aluminum products like extrusion 6063 scrap.

5. What are some sustainability benefits of recycling aluminum extrusion 6063?

Recycling aluminum extrusion 6063 reduces energy consumption compared to producing new aluminum from raw materials and decreases greenhouse gas emissions associated with mining and processing bauxite ore.