Content Menu

● Understanding the Importance of Extrusion Equipment Repairs

>> Types of Extrusion Equipment Repairs

● Finding Reliable Repair Service Providers

● Common Maintenance Techniques

>> Screw and Barrel Maintenance

>> Electrical and Mechanical Checks

● Solutions to Common Issues

>> Common Extruder Faults

● Advanced Maintenance Strategies

>> Predictive Maintenance

>> Condition-Based Maintenance

● Conclusion

● FAQ

>> 1. How Do I Choose a Reliable Repair Service Provider?

>> 2. What Are the Main Steps in Extrusion Equipment Maintenance?

>> 3. How Can I Prevent Screw and Barrel Clogging?

>> 4. How Do I Prevent Electrical Faults?

>> 5. How Do I Handle Common Extruder Faults?

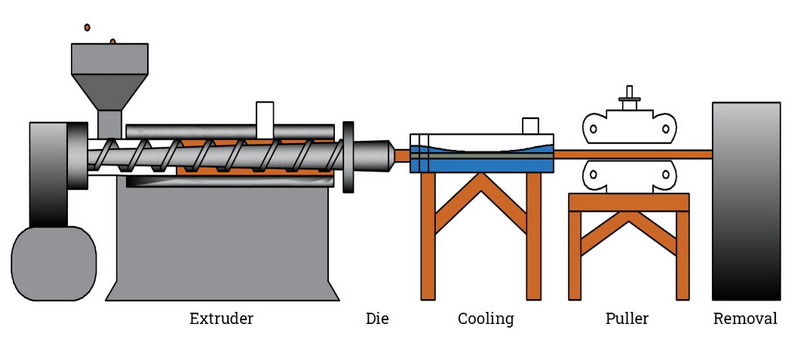

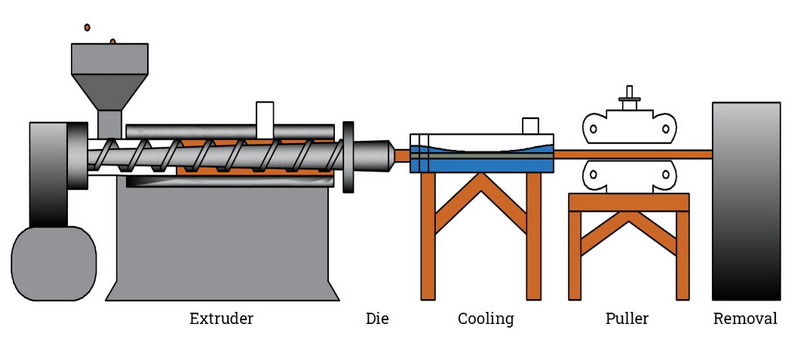

Finding reliable extrusion equipment repairs is crucial for maintaining the efficiency and quality of production in industries such as plastics and rubber manufacturing. Extrusion equipment plays a vital role in these processes, and its maintenance directly impacts the stability and productivity of production lines. This article provides a comprehensive guide on how to locate trustworthy repair services for extrusion equipment, including types of repairs, maintenance techniques, and solutions to common issues.

Understanding the Importance of Extrusion Equipment Repairs

Extrusion equipment is a critical component in the production of plastics and rubber. Regular maintenance and timely repairs are essential to prevent equipment failures, which can lead to costly downtime and reduced product quality. By ensuring that extrusion equipment operates smoothly, manufacturers can maintain high production standards and meet customer demands effectively.

Types of Extrusion Equipment Repairs

1. Routine Maintenance: This includes cleaning, lubrication, and checking electrical connections to ensure the equipment runs smoothly.

Routine maintenance is essential for preventing minor issues from escalating into major problems. Regular cleaning helps remove residue that can accumulate and cause blockages, while lubrication reduces wear on moving parts. Electrical checks ensure that all connections are secure and functioning correctly.

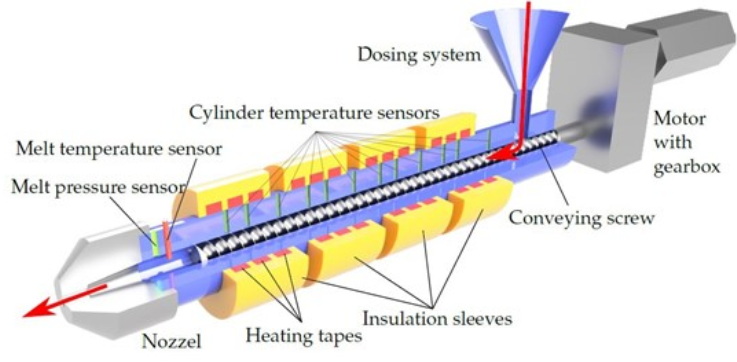

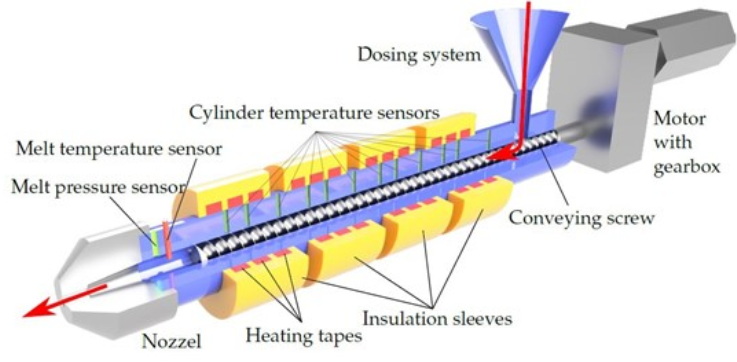

2. Deep Maintenance: This involves replacing parts, cleaning, and inspecting major components like screws and barrels.

Deep maintenance is more intensive and typically requires specialized tools and expertise. It involves dismantling parts of the extruder to inspect and replace worn-out components. This type of maintenance is crucial for extending the lifespan of the equipment and ensuring optimal performance.

Finding Reliable Repair Service Providers

When searching for reliable repair services, several factors should be considered:

1. Experience and Expertise: Choose providers with extensive experience and specialized knowledge in extrusion equipment repairs.

Experienced technicians understand the intricacies of different extrusion systems and can diagnose problems efficiently. Their expertise ensures that repairs are done correctly the first time, minimizing downtime.

2. Service Range: Ensure the provider offers comprehensive services, including emergency repairs and scheduled maintenance.

A provider that offers a wide range of services can cater to both urgent and routine needs. This flexibility is crucial for maintaining production schedules and responding to unexpected breakdowns.

3. Customer Reviews: Check customer testimonials to gauge the provider's reliability and service quality.

Positive reviews from previous clients can provide assurance about the quality of service and the provider's ability to meet deadlines and budgets.

Common Maintenance Techniques

Understanding basic maintenance techniques can help you address common issues promptly.

Screw and Barrel Maintenance

- Cleaning: Regularly clean the screw and barrel to prevent residue buildup.

Cleaning involves using specialized tools to remove accumulated material that can affect the extrusion process. This process should be done regularly to maintain efficiency and prevent blockages.

- Lubrication: Ensure all moving parts are properly lubricated to reduce friction and wear.

Lubrication is critical for extending the lifespan of moving parts. It reduces heat generated by friction, which can damage components over time.

Electrical and Mechanical Checks

- Electrical Checks: Regularly inspect electrical connections to ensure safety and reliability.

Electrical checks involve verifying that all connections are secure and not damaged. This helps prevent electrical faults that could lead to equipment failure or safety hazards.

- Mechanical Checks: Inspect mechanical components for wear and replace them as needed.

Mechanical checks involve examining parts like gears, bearings, and seals for signs of wear. Replacing worn parts proactively can prevent unexpected breakdowns.

Solutions to Common Issues

Common Extruder Faults

1. Unstable Current: Check for uneven feeding or main motor bearing damage.

Unstable current can be caused by inconsistent material feeding or issues with the main motor. Checking the feeding system and motor bearings can help diagnose the problem.

2. Main Motor Failure to Start: Check the startup procedure and wiring for any issues.

If the main motor fails to start, ensure that the startup sequence is correct and check for any wiring faults. This could involve inspecting fuses, circuit breakers, or contactors.

3. Poor Output from the Die Head: Check if the heaters are functioning correctly and if there are any blockages.

Poor output from the die head can be due to malfunctioning heaters or blockages in the die. Checking the heating elements and ensuring that the die is clear of debris can resolve this issue.

4. Overheating: Check bearing lubrication and ensure there are no overheating conditions.

Overheating can be caused by inadequate lubrication of bearings or other mechanical issues. Monitoring temperature sensors and ensuring proper cooling systems are in place can help prevent overheating.

5. Low Oil Pressure: Check pressure regulator settings and ensure there are no blockages in the pump or intake lines.

Low oil pressure can be due to incorrect pressure settings or blockages in the hydraulic system. Checking the pressure regulator and ensuring that all lines are clear can resolve this issue.

Advanced Maintenance Strategies

In addition to routine and deep maintenance, adopting advanced strategies can further enhance equipment performance and longevity.

Predictive Maintenance

Predictive maintenance involves using sensors and data analytics to predict when maintenance is required. This approach allows for proactive maintenance, reducing unexpected downtime and extending equipment lifespan.

Condition-Based Maintenance

Condition-based maintenance involves performing maintenance based on the actual condition of the equipment rather than on a fixed schedule. This approach ensures that maintenance is done only when necessary, optimizing resource usage.

Conclusion

Finding reliable extrusion equipment repairs is essential for maintaining production efficiency and quality. By understanding the types of repairs, adopting effective maintenance techniques, and addressing common issues promptly, manufacturers can ensure their extrusion equipment operates at optimal levels. Regular maintenance not only extends the lifespan of the equipment but also reduces the risk of unexpected failures, thereby minimizing production downtime.

FAQ

1. How Do I Choose a Reliable Repair Service Provider?

Choose a provider based on their experience, expertise, service range, and customer reviews. Ensure they have a proven track record in handling similar equipment and can meet your specific needs.

2. What Are the Main Steps in Extrusion Equipment Maintenance?

The main steps include routine maintenance (cleaning, lubrication, electrical checks) and deep maintenance (replacing parts, cleaning major components).

3. How Can I Prevent Screw and Barrel Clogging?

Regular cleaning and ensuring proper material flow can prevent clogging. Using the right cleaning tools and techniques is crucial for maintaining efficiency.

4. How Do I Prevent Electrical Faults?

Regularly inspect electrical connections to ensure they are secure and not damaged. This helps prevent electrical faults that could lead to equipment failure or safety hazards.

5. How Do I Handle Common Extruder Faults?

Address faults based on their nature. For example, check feeding systems for uneven feeding, inspect motor bearings for damage, and ensure heaters are functioning correctly for output issues.