Content Menu

● Understanding Aluminum Extrusion

>> Benefits of Aluminum Extrusion

● Key Factors to Consider When Choosing an Aluminum Extrusion Company

>> Experience and Expertise

>> Quality Assurance

>> Customization Capabilities

>> Production Capacity

>> Material Selection

>> Customer Support

>> Pricing and Cost Transparency

>> Location and Logistics

● The Selection Process

>> Step 1: Research and Shortlist

>> Step 2: Request Proposals

>> Step 3: Evaluate Proposals

>> Step 4: Conduct Interviews

>> Step 5: Make Your Decision

● Additional Considerations

>> Industry Trends

>> Sustainability Practices

>> Long-Term Partnerships

● Conclusion

● Frequently Asked Questions

>> 1. What is aluminum extrusion?

>> 2. How do I know if an aluminum extrusion company is reputable?

>> 3. Can I get custom aluminum extrusions?

>> 4. What factors affect the cost of aluminum extrusions?

>> 5. How long does the aluminum extrusion process take?

Understanding Aluminum Extrusion

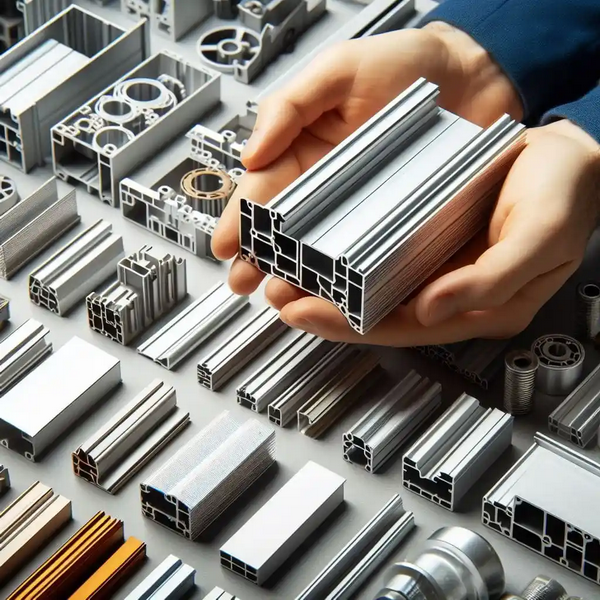

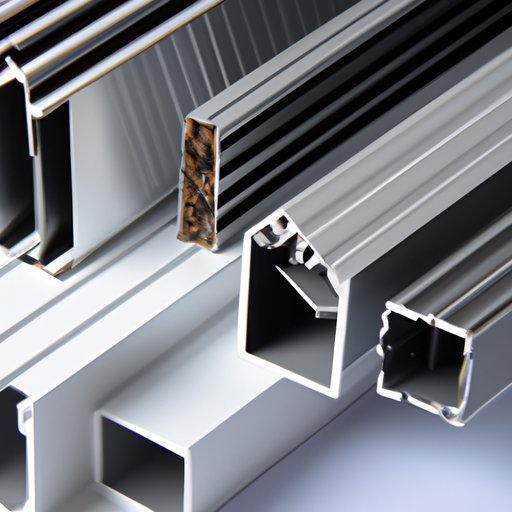

Before diving into the selection process, it's essential to understand what aluminum extrusion entails. The extrusion process involves forcing aluminum alloy through a die to create a specific shape. This method allows for the production of complex profiles that can be tailored to meet specific design requirements. The versatility of aluminum makes it a popular choice in industries such as automotive, aerospace, construction, and consumer goods.

Benefits of Aluminum Extrusion

1. Lightweight and Durable: Aluminum is known for its lightweight properties, making it an ideal choice for applications where weight reduction is critical. Despite its lightness, aluminum is also highly durable and resistant to corrosion.

2. Design Flexibility: The extrusion process allows for a wide range of shapes and sizes, enabling designers to create custom profiles that meet their specific needs.

3. Cost-Effectiveness: Aluminum extrusion can be a cost-effective solution for large-scale production, as it minimizes waste and reduces manufacturing costs.

4. Sustainability: Aluminum is 100% recyclable, making it an environmentally friendly choice for manufacturers and consumers alike.

Key Factors to Consider When Choosing an Aluminum Extrusion Company

When selecting an aluminum extrusion company, several factors should be taken into account to ensure you make the best choice for your project.

Experience and Expertise

Look for a company with a proven track record in the aluminum extrusion industry. An experienced supplier will have the knowledge and skills necessary to handle complex projects and provide valuable insights throughout the design and manufacturing process. Check their portfolio for past projects and client testimonials to gauge their expertise.

Quality Assurance

Quality should be a top priority when choosing an aluminum extrusion company. Inquire about their quality control processes and certifications. A reputable company will adhere to industry standards and have measures in place to ensure that their products meet or exceed quality expectations.

Customization Capabilities

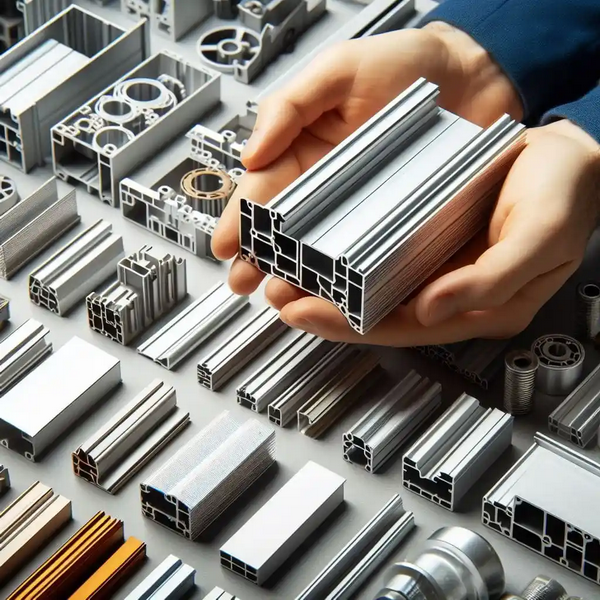

If your project requires custom profiles, it's essential to choose a company that offers customization options. Discuss your specific design requirements and ask about their ability to create tailored solutions. A flexible supplier will work with you to develop the right profile for your application.

Production Capacity

Consider the production capacity of the aluminum extrusion company. If you have a large order or tight deadlines, ensure that the supplier can meet your demands without compromising quality. Ask about their lead times and production capabilities to avoid delays in your project.

Material Selection

Different aluminum alloys have varying properties that make them suitable for specific applications. Discuss your project requirements with the supplier to determine the best material for your needs. A knowledgeable company will guide you in selecting the right alloy based on factors such as strength, corrosion resistance, and weight.

Customer Support

Effective communication and customer support are vital when working with an aluminum extrusion company. Choose a supplier that is responsive to your inquiries and provides clear information throughout the process. A company that values customer service will be more likely to address any concerns and ensure a smooth collaboration.

Pricing and Cost Transparency

While cost should not be the sole determining factor, it is essential to understand the pricing structure of the aluminum extrusion company. Request quotes from multiple suppliers and compare their pricing, taking into account the quality of materials and services offered. Look for transparency in pricing to avoid hidden costs later in the project.

Location and Logistics

Consider the location of the aluminum extrusion company in relation to your project site. A local supplier may offer advantages in terms of shipping costs and lead times. Additionally, inquire about their logistics capabilities to ensure timely delivery of your products.

The Selection Process

Once you have identified potential aluminum extrusion companies, follow these steps to make an informed decision:

Step 1: Research and Shortlist

Conduct thorough research to identify aluminum extrusion companies that meet your criteria. Create a shortlist of potential suppliers based on their experience, capabilities, and reputation.

Step 2: Request Proposals

Reach out to the shortlisted companies and request proposals. Provide them with detailed information about your project, including design specifications, quantities, and timelines. This will allow them to provide accurate quotes and insights.

Step 3: Evaluate Proposals

Review the proposals you receive, paying close attention to pricing, lead times, and customization options. Compare the strengths and weaknesses of each supplier to determine which one aligns best with your project needs.

Step 4: Conduct Interviews

If possible, conduct interviews or meetings with the top candidates. This will give you an opportunity to ask questions, clarify any concerns, and assess their level of expertise and customer service.

Step 5: Make Your Decision

After evaluating all factors, make your final decision based on the supplier that best meets your project requirements. Ensure that you have a clear understanding of the terms and conditions before proceeding with the order.

Additional Considerations

Industry Trends

Staying informed about industry trends can also influence your choice of an aluminum extrusion company. The aluminum industry is continuously evolving, with advancements in technology, materials, and processes. Companies that invest in the latest technologies and sustainable practices are often better positioned to meet the demands of modern projects. Look for suppliers that are committed to innovation and sustainability, as these factors can enhance the overall quality and efficiency of your project.

Sustainability Practices

As environmental concerns grow, many companies are prioritizing sustainability in their operations. When selecting an aluminum extrusion company, inquire about their sustainability practices. Do they use recycled materials? What measures do they take to minimize waste during production? A company that prioritizes sustainability not only contributes to environmental conservation but may also offer you a competitive advantage in your market.

Long-Term Partnerships

Consider the potential for a long-term partnership with the aluminum extrusion company. If you anticipate ongoing projects or require regular supplies, establishing a strong relationship with a reliable supplier can lead to better pricing, priority service, and improved collaboration. Look for a company that values long-term partnerships and is willing to invest in your success.

Conclusion

Choosing the right aluminum extrusion company for your project in the USA is a critical step that can significantly impact the success of your endeavor. By considering factors such as experience, quality assurance, customization capabilities, and customer support, you can make an informed decision that aligns with your project goals. Remember to conduct thorough research, evaluate proposals, and communicate effectively with potential suppliers to ensure a successful partnership.

Frequently Asked Questions

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy by forcing it through a die to create a specific cross-sectional profile. This process allows for the production of complex shapes that can be used in various applications.

2. How do I know if an aluminum extrusion company is reputable?

Look for companies with a proven track record, positive client testimonials, industry certifications, and a portfolio of successful projects. Research their history and ask for references to gauge their reliability.

3. Can I get custom aluminum extrusions?

Yes, many aluminum extrusion companies offer customization options to create profiles tailored to your specific design requirements. Discuss your needs with potential suppliers to find the best fit.

4. What factors affect the cost of aluminum extrusions?

Factors include material selection, complexity of the design, production volume, and any additional services such as finishing or assembly. It's essential to discuss these factors with your supplier to get an accurate quote.

5. How long does the aluminum extrusion process take?

Lead times can vary based on the supplier and the complexity of the project, but it's essential to discuss timelines during the selection process. Ensure that the company can meet your deadlines without compromising quality.