Content Menu

● Understanding Aluminum Extrusion

>> Benefits of Using Aluminum Extrusion

● Materials Needed

>> 1. Aluminum Extrusion Profiles

>> 2. Corner Brackets

>> 3. Fasteners

>> 4. Racing Seat

>> 5. Steering Wheel and Pedals

>> 6. Monitor Mount

>> 7. Optional Accessories

● Step-by-Step Assembly Guide

>> Step 1: Planning Your Design

>> Step 2: Gather Your Materials

>> Step 3: Assemble the Base Frame

>> Step 4: Add Vertical Supports

>> Step 5: Install the Racing Seat

>> Step 6: Attach the Steering Wheel and Pedals

>> Step 7: Add Monitor Mount (Optional)

>> Step 8: Final Adjustments

● Tips for Success

● Conclusion

● Related Questions and Answers

>> 1.What tools do I need to build a DIY aluminum extrusion sim rig?

>> 2.Can I use any type of racing seat with my sim rig?

>> 3.Is it possible to add more features to my sim rig later?

>> 4.How do I ensure my sim rig is stable?

>> 5.What are some common mistakes to avoid when building a sim rig?

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. This method is popular for creating structural components due to its lightweight, strength, and versatility. In the context of sim rigs, aluminum extrusions are used to create a sturdy frame that can support various components such as racing seats, steering wheels, and pedals.

Benefits of Using Aluminum Extrusion

1. Lightweight and Strong: Aluminum is known for its high strength-to-weight ratio, making it ideal for building a robust yet lightweight sim rig.

2. Modular Design: The modular nature of aluminum extrusions allows for easy adjustments and expansions. You can add or remove components as needed without major modifications.

3. No Cutting Required: Many suppliers offer pre-cut lengths of aluminum extrusion, which means you can build your rig without the need for cutting tools.

4. Aesthetic Appeal: Aluminum has a sleek, modern look that can enhance the overall appearance of your gaming setup.

Materials Needed

To build your DIY aluminum extrusion sim rig without cutting any materials, you will need the following components:

1. Aluminum Extrusion Profiles

Choose the appropriate size and length of aluminum extrusion profiles. Common sizes include 20mm x 20mm or 40mm x 40mm. You can purchase these from local hardware stores or online suppliers. The choice of size will depend on the overall design and the weight of the components you plan to mount.

2. Corner Brackets

Corner brackets are essential for connecting the aluminum profiles at right angles. They provide stability and strength to the structure. Look for brackets that are compatible with the size of your aluminum profiles to ensure a secure fit.

3. Fasteners

You will need various fasteners, such as T-nuts and bolts, to secure the aluminum profiles and corner brackets together. Ensure that the fasteners are compatible with the size of your aluminum extrusion. Using high-quality fasteners will help maintain the integrity of your rig over time.

4. Racing Seat

Select a racing seat that fits your comfort and style preferences. Many sim racers opt for bucket-style seats, which provide excellent support during long gaming sessions. Consider the seat's mounting options and ensure it can be securely attached to your rig.

5. Steering Wheel and Pedals

Choose a steering wheel and pedal set that suits your gaming style. Brands like Logitech, Thrustmaster, and Fanatec offer a range of options for different budgets. Ensure that the steering wheel is compatible with your gaming platform and that the pedals provide the necessary feedback for an immersive experience.

6. Monitor Mount

If you plan to use a monitor, consider a monitor mount that can be attached to the rig. This will help you achieve the optimal viewing angle for your racing games. Adjustable mounts are ideal as they allow you to change the height and angle based on your seating position.

7. Optional Accessories

Depending on your preferences, you may want to add accessories such as a gear shifter, button box, or additional monitors for a more immersive experience. These accessories can enhance your racing experience and provide more control during gameplay.

Step-by-Step Assembly Guide

Step 1: Planning Your Design

Before you start assembling your sim rig, take some time to plan your design. Sketch out a rough layout of how you want your rig to look, including the placement of the seat, steering wheel, and pedals. Consider the dimensions of your space to ensure that the rig will fit comfortably.

Step 2: Gather Your Materials

Once you have your design in mind, gather all the materials you will need. Ensure that you have enough aluminum profiles, corner brackets, and fasteners to complete the build. Having everything ready will streamline the assembly process.

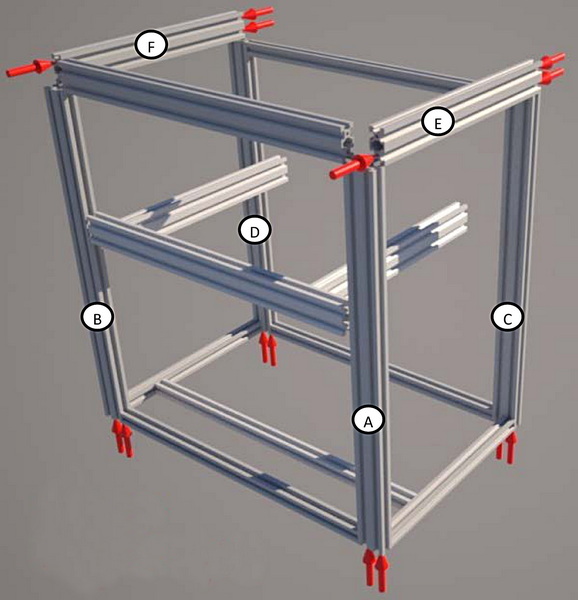

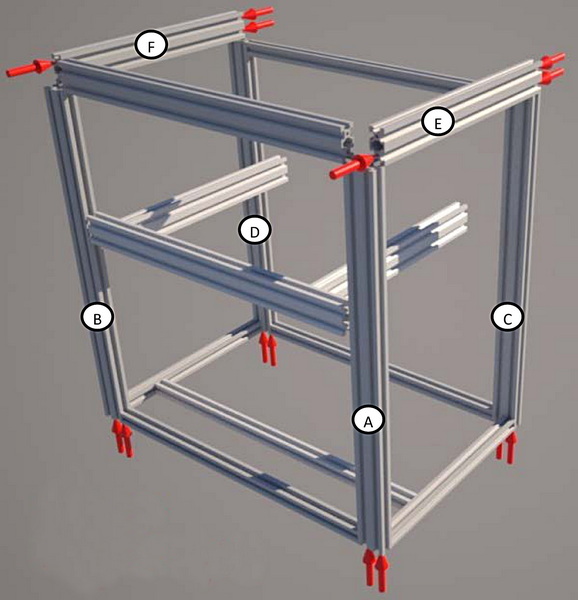

Step 3: Assemble the Base Frame

1. Lay Out the Profiles: Start by laying out the aluminum profiles on the floor according to your design. This will help you visualize the structure before assembly.

2. Attach Corner Brackets: Use corner brackets to connect the profiles at the corners. Secure them with T-nuts and bolts, ensuring that everything is tight and stable.

3. Create the Base: Assemble the base of the rig first, ensuring it is square and level. This will provide a solid foundation for the rest of the rig.

Step 4: Add Vertical Supports

Once the base is complete, add vertical supports to create the frame for the seat and steering wheel. Use additional aluminum profiles and corner brackets to secure these supports in place. Make sure the vertical supports are aligned properly to maintain the overall structure's integrity.

Step 5: Install the Racing Seat

1. Position the Seat: Place the racing seat on the frame and adjust its position according to your comfort. Ensure that it is at a height that allows for easy access to the steering wheel and pedals.

2. Secure the Seat: Use additional aluminum profiles to create a mounting bracket for the seat. Secure it with fasteners to ensure it is stable. Test the seat's stability by applying pressure to ensure it can withstand the movements during gameplay.

Step 6: Attach the Steering Wheel and Pedals

1. Mount the Steering Wheel: Use a steering wheel stand or create a custom mount using aluminum profiles. Ensure that the steering wheel is at a comfortable height and angle for driving. You may want to adjust the angle based on your seating position for optimal control.

2. Install the Pedals: Position the pedals in front of the seat, ensuring they are easily accessible. Secure them to the frame using brackets or additional profiles. Make sure the pedals are stable and do not move during use.

Step 7: Add Monitor Mount (Optional)

If you are using a monitor, attach the monitor mount to the rig. Adjust the height and angle to achieve the best viewing experience. Consider using a dual monitor setup for a more immersive experience, especially if you enjoy racing simulations that benefit from peripheral vision.

Step 8: Final Adjustments

Once everything is assembled, take some time to make final adjustments. Ensure that all components are secure and that the rig is stable. Test the setup to ensure that everything is functioning correctly. Adjust the seat, steering wheel, and pedals as needed for comfort and accessibility.

Tips for Success

- Take Your Time: Building a sim rig can be a time-consuming process, so be patient and take your time to ensure everything is done correctly. Rushing through the assembly can lead to mistakes that may require rework.

- Ask for Help: If you are unsure about any part of the assembly, don't hesitate to ask for help from friends or online communities. Many sim racing forums have experienced builders who can offer advice and tips.

- Customize as Needed: Feel free to customize your rig with additional features or accessories that enhance your gaming experience. Personal touches can make your rig feel unique and tailored to your preferences.

Conclusion

Building a DIY aluminum extrusion sim rig without cutting any materials is a rewarding project that can enhance your sim racing experience. By following the steps outlined in this article and utilizing the right materials, you can create a custom rig that meets your needs and preferences. Remember to take your time, make adjustments as needed, and most importantly, enjoy the process of building your own racing setup.

Related Questions and Answers

1.What tools do I need to build a DIY aluminum extrusion sim rig?

You will primarily need a hex key or wrench for tightening bolts and T-nuts. A level and measuring tape can also be helpful for ensuring everything is aligned correctly. Additionally, having a screwdriver and pliers on hand can assist with various assembly tasks.

2.Can I use any type of racing seat with my sim rig?

Yes, you can use various types of racing seats, but ensure that the seat you choose is compatible with the mounting system you create. Some seats come with universal mounting brackets, while others may require custom solutions.

3.Is it possible to add more features to my sim rig later?

Absolutely! The modular design of aluminum extrusion allows you to easily add features like additional monitors, a gear shifter, or even a button box. This flexibility means you can upgrade your rig as your needs and preferences evolve.

4.How do I ensure my sim rig is stable?

Make sure all connections are tight and secure. Using a wider base and additional cross-bracing can also enhance stability. Regularly check the fasteners and connections to ensure they remain secure over time.

5.What are some common mistakes to avoid when building a sim rig?

Common mistakes include not planning the design properly, using insufficient fasteners, and neglecting to test the stability of the rig before use. Additionally, overlooking the ergonomics of the setup can lead to discomfort during long gaming sessions.