Content Menu

● Introduction to Extrusion Machinery Supplies

>> Importance of Quality Extrusion Machinery Supplies

● Enhancing Production Efficiency with Extrusion Machinery Supplies

>> 1. Automation and Real-Time Monitoring

>> 2. Optimization of Material Selection and Usage

>> 3. Advanced Equipment and Technology

>> 4. Downstream Equipment and Post-Extrusion Processes

>> 5. Troubleshooting and Maintenance

● Common Challenges in Extrusion Production

>> Overcoming Challenges with Extrusion Machinery Supplies

● Conclusion

● FAQ

>> 1. What are the key benefits of using extrusion machinery supplies in production?

>> 2. How does automation improve extrusion production efficiency?

>> 3. What role does material selection play in optimizing extrusion production?

>> 4. What are common challenges faced in extrusion production and how can they be addressed?

>> 5. How does downstream equipment contribute to the efficiency of extrusion production?

● Citations:

Extrusion machinery supplies play a crucial role in enhancing production efficiency across various industries, including plastics, metals, and food processing. These supplies encompass a wide range of equipment and components designed to optimize the extrusion process, ensuring high-quality outputs while minimizing costs and environmental impact. In this article, we will delve into the ways extrusion machinery supplies can improve production efficiency, explore common challenges, and discuss troubleshooting strategies.

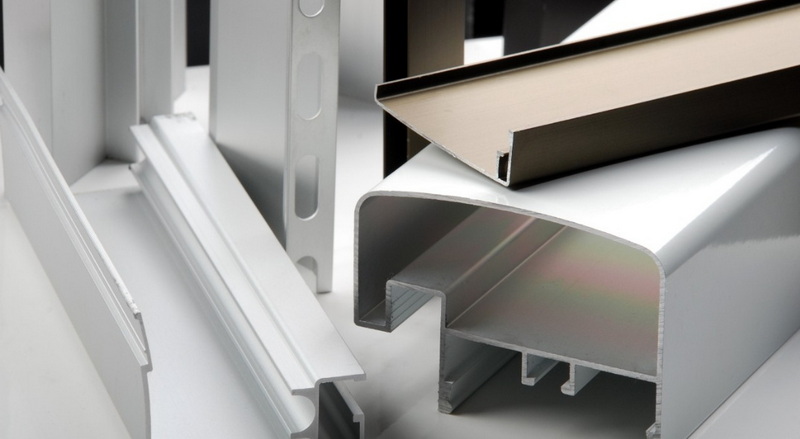

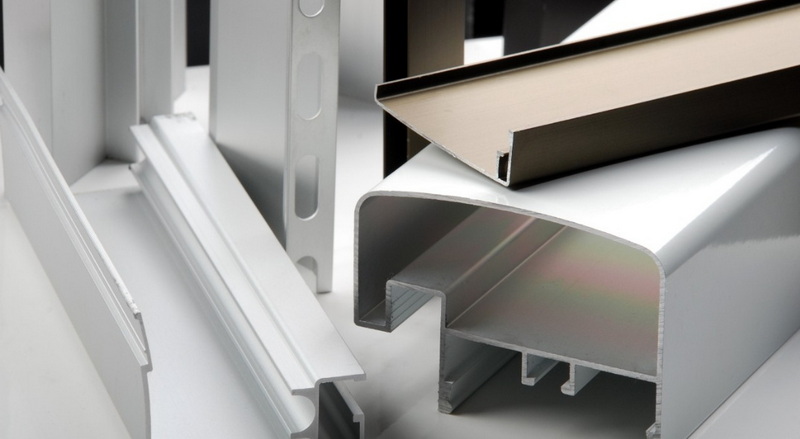

Introduction to Extrusion Machinery Supplies

Extrusion machinery supplies include everything from extruders and dies to downstream equipment like haul-off belts and cutting tools. These components are essential for maintaining a smooth and efficient production line. For instance, high-quality extruders ensure consistent material flow, while precision dies guarantee accurate product dimensions.

Importance of Quality Extrusion Machinery Supplies

Quality extrusion machinery supplies are critical for several reasons:

1. Consistency and Accuracy: High-quality supplies ensure that products are manufactured with precise dimensions and consistent quality, meeting customer specifications and enhancing brand reputation.

2. Efficiency and Cost Savings: Efficient machinery reduces energy consumption and minimizes waste, leading to cost savings and improved profitability.

3. Reliability and Durability: Durable equipment requires less maintenance, reducing downtime and increasing overall production capacity.

Enhancing Production Efficiency with Extrusion Machinery Supplies

1. Automation and Real-Time Monitoring

Incorporating automation and real-time monitoring systems into extrusion lines can significantly improve efficiency and accuracy. Automated systems control parameters like temperature, pressure, and speed, ensuring optimal performance at all times. Real-time monitoring allows operators to quickly identify and address anomalies before they escalate into larger problems.

2. Optimization of Material Selection and Usage

Optimizing material selection and usage is another key strategy. Choosing the right materials can reduce production costs and improve product quality. Additionally, using recycled materials can enhance sustainability by reducing waste and carbon emissions.

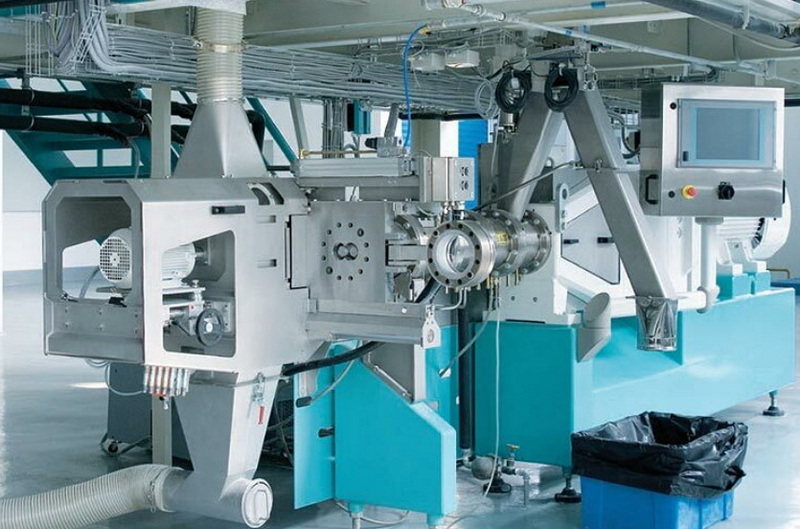

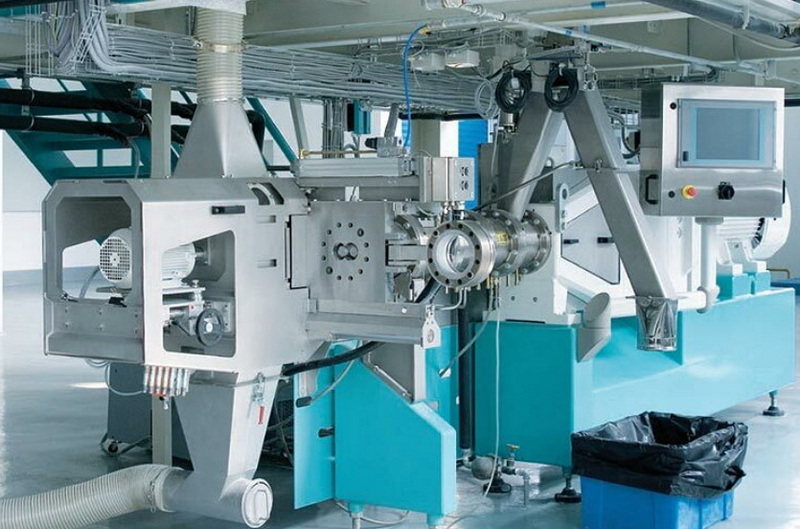

3. Advanced Equipment and Technology

Investing in advanced extrusion equipment and technology is vital for improving efficiency. Modern machinery often features advanced automation systems, precision temperature control, and high-speed production capabilities. These technologies not only enhance product quality but also reduce labor costs and increase production capacity.

4. Downstream Equipment and Post-Extrusion Processes

Downstream equipment such as vacuum sizing tanks, haul-off belts, and cutting tools are crucial for ensuring the smooth operation of the extrusion line. These components help maintain product quality, reduce waste, and enhance overall efficiency.

5. Troubleshooting and Maintenance

Regular maintenance and troubleshooting are essential for preventing downtime and maintaining efficiency. Common issues include material feeding problems, overheating, and equipment wear. Implementing a systematic troubleshooting approach can quickly resolve these issues and ensure continuous production.

Common Challenges in Extrusion Production

Despite the benefits of extrusion machinery supplies, several challenges can arise during production:

1. Material Quality Issues: Poor material quality can lead to defects like uneven surfaces or inconsistent dimensions.

2. Equipment Malfunctions: Issues with heaters, motors, or other components can halt production.

3. Environmental Factors: Temperature fluctuations or humidity can affect material properties and product quality.

Overcoming Challenges with Extrusion Machinery Supplies

To overcome these challenges, manufacturers can:

1. Implement Quality Control Measures: Regularly inspect materials and equipment to prevent defects.

2. Invest in Advanced Technology: Use automated systems and precision machinery to minimize human error.

3. Optimize Production Conditions: Control environmental factors to ensure consistent product quality.

Conclusion

Extrusion machinery supplies are indispensable for enhancing production efficiency in various manufacturing sectors. By leveraging automation, optimizing material selection, investing in advanced equipment, and maintaining effective downstream processes, manufacturers can significantly improve their production capabilities. Additionally, addressing common challenges through regular maintenance and troubleshooting ensures continuous operation and high-quality outputs.

FAQ

1. What are the key benefits of using extrusion machinery supplies in production?

- Answer: The key benefits include improved efficiency, enhanced product quality, reduced costs, and increased sustainability through waste reduction and energy efficiency.

2. How does automation improve extrusion production efficiency?

- Answer: Automation improves efficiency by controlling parameters like temperature and pressure, reducing manual intervention, and enabling real-time monitoring to quickly address anomalies.

3. What role does material selection play in optimizing extrusion production?

- Answer: Material selection is crucial as it affects product quality, production costs, and environmental impact. Choosing the right materials can reduce waste and enhance sustainability.

4. What are common challenges faced in extrusion production and how can they be addressed?

- Answer: Common challenges include material quality issues and equipment malfunctions. These can be addressed through quality control measures, regular maintenance, and investing in advanced technology.

5. How does downstream equipment contribute to the efficiency of extrusion production?

- Answer: Downstream equipment like vacuum sizing tanks and haul-off belts ensures consistent product quality, reduces waste, and enhances overall production efficiency by maintaining precise product dimensions and minimizing defects.

Citations:

[1] https://www.faygounion.com/news/5-ways-to-improve-efficiency-in-plastic-extrusion-lines/

[2] https://www.longshengmfg.com/extrusion-moulding-understanding-the-process-and-its-benefits/

[3] https://www.alamy.com/stock-photo/extrusion-machine.html

[4] https://www.youtube.com/watch?v=Y75IQksBb0M

[5] https://www.adremac.com/complete-guide-to-pipe-extrusion-machinery-equipment-and-advanced-cutting-solutions/

[6] https://www.elastron.com/en/12-extrusion-defects-and-troubleshooting-elastron-tpe

[7] https://community.xometry.com/kb/articles/761-metal-extrusion-frequently-asked-questions

[8] https://www.linkedin.com/pulse/some-ways-improving-extrusion-production-efficiency-stan-hua

[9] https://jieyatwinscrew.com/blog/exploring-the-world-of-extrusion-machines-understanding-the-basics-and-benefits/

[10] https://www.jwellextrusions.com/video/

[11] https://www.asaclean.com/blog/addressing-common-issues-in-twin-screw-extrusion-troubleshooting-guide

[12] https://www.yjing-extrusion.com/how-does-extrusion-production-benefit-manufacturing-industries.html

[13] https://www.plastar-machine.com/en/article/blown-film-extrusion-troubleshooting-guide.html

[14] https://www.jwellextrusions.com/common-faults-of-extrusion-machine-and-the-related-causes.html

[15] https://ohmvo.com/silicone-barrel-heaters-enhancing-efficiency-in-plastic-extrusion/

[16] https://www.tahara-mc.com/en/2023/09/07/improve-production-efficiency-with-auxiliary-equipment/

[17] https://plasticextrusiontech.net/benefits-of-plastic-extrusion/

[18] https://www.satorianalytics.com/casestudy15.html

[19] https://reifenhauser.com/en/company/media/news-and-stories/success-story/increase-productivity-plastics-extrusion

[20] https://www.fangliextru.com/news-show-1069125.html

[21] https://www.atieuno.com/project/extrusion-management-system-case-study/

[22] https://abhiplastics.com/the-ultimate-guide-to-boosting-productivity-with-plastic-extrusion-machines/

[23] https://plasticextrusiontech.net/what-are-the-benefits-of-using-plastic-extrusions-over-other-materials/

[24] https://sciendo.com/article/10.2478/mspe-2024-0042

[25] https://www.yjing-extrusion.com/how-to-improve-efficiency-in-blown-film-extrusion-equipment.html

[26] https://www.databridgemarketresearch.com/reports/global-extrusion-machinery-market

[27] https://www.istockphoto.com/photos/extrusion

[28] https://www.shutterstock.com/search/extrusion-machine

[29] https://stock.adobe.com/search/images?k=extrusion+equipment

[30] https://www.youtube.com/watch?v=BDBsxQBEo3g