Content Menu

● Introduction to Extrusion Machinery

● Strategies for Enhancing Efficiency

>> 1. Automation and Advanced Control Systems

>> 2. Customized Screw and Die Designs

>> 3. Material Selection and Compatibility

>> 4. Employee Training and Engagement

>> 5. After-Sales Support and Maintenance

● Case Studies: Success Stories with Extrusion Machinery Sales Ltd

● Industry Applications of Extrusion Machinery

>> Plastics Industry

>> Metals Industry

>> Food Processing

● Future Trends in Extrusion Technology

● Collaboration and Innovation

● Conclusion

● Frequently Asked Questions

>> 1. What are the key components of an extrusion machine?

>> 2. How does automation improve extrusion efficiency?

>> 3. What is the importance of customized screw and die designs?

>> 4. Why is material selection crucial in extrusion?

>> 5. What kind of support does Extrusion Machinery Sales Ltd offer?

In today's fast-paced manufacturing landscape, optimizing production efficiency is crucial for businesses to remain competitive. Extrusion Machinery Sales Ltd specializes in providing cutting-edge solutions to enhance the productivity of various industries, including plastics, metals, and food processing. This article explores how Extrusion Machinery Sales Ltd can help improve your production efficiency through advanced technology, strategic planning, and expert support.

Introduction to Extrusion Machinery

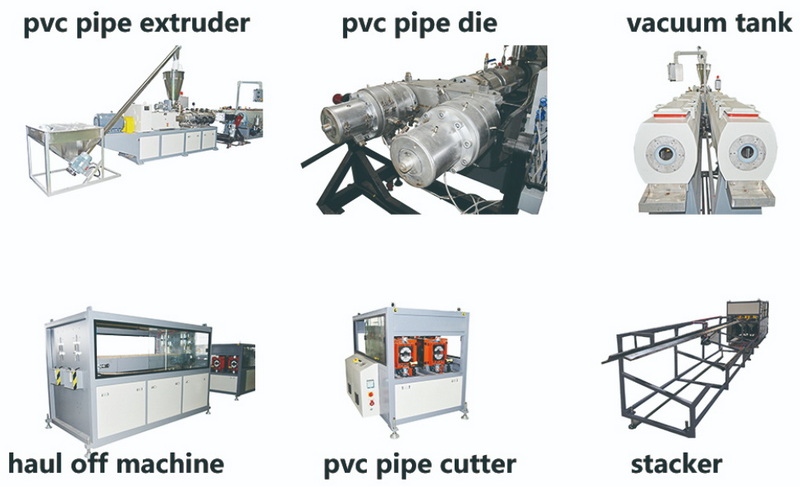

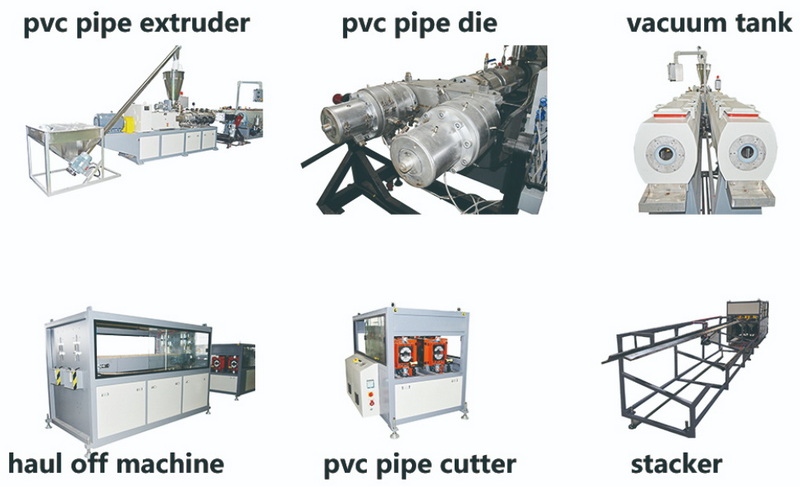

Extrusion machinery is designed to transform raw materials into finished products by forcing them through a die under high pressure. This process is widely used in manufacturing sectors such as plastics, metals, and even food production. The key components of an extrusion machine include the feed hopper, barrel and screw, die, heating and cooling systems, drive motor, and control systems.

Extrusion machines can be categorized based on their application, such as single-screw extruders, twin-screw extruders, and co-rotating or counter-rotating configurations. Each type offers unique advantages depending on the material and desired product properties.

Strategies for Enhancing Efficiency

1. Automation and Advanced Control Systems

Extrusion Machinery Sales Ltd offers machines equipped with advanced automation and control systems. These systems allow for precise regulation of temperature, pressure, and speed, ensuring optimal performance and reducing manual errors. By integrating real-time monitoring and analytics, manufacturers can quickly identify and address any issues before they impact production. Automation also enables the collection of data for future process improvements, helping to refine production parameters over time.

2. Customized Screw and Die Designs

Customizing screw geometry and die designs to match specific materials and applications can significantly improve melt quality and throughput. Extrusion Machinery Sales Ltd works closely with clients to design and implement these customizations, ensuring efficient material conversion and higher-quality products. For instance, in plastic extrusion, a customized screw design can enhance mixing efficiency, leading to more consistent product properties.

3. Material Selection and Compatibility

Choosing the right materials for your extrusion process is vital. Extrusion Machinery Sales Ltd helps manufacturers select materials that are compatible with their machinery, ensuring smooth production and minimizing potential chemical reactions with machine parts. This includes advising on additives, fillers, and other components that can enhance product performance without compromising machinery longevity.

4. Employee Training and Engagement

Providing comprehensive training for operators is essential for maximizing the potential of extrusion machinery. Extrusion Machinery Sales Ltd offers training programs that empower operators to make informed decisions, troubleshoot issues, and optimize production parameters. Engaged and knowledgeable staff are more likely to identify opportunities for improvement and contribute to continuous process optimization.

5. After-Sales Support and Maintenance

Extrusion Machinery Sales Ltd emphasizes the importance of after-sales support, including installation assistance, maintenance guidance, and ongoing technical support. This ensures that machinery operates at peak performance and minimizes downtime. Regular maintenance can prevent costly repairs and extend the lifespan of the equipment, further enhancing overall efficiency.

Case Studies: Success Stories with Extrusion Machinery Sales Ltd

Several companies have seen significant improvements in production efficiency by partnering with Extrusion Machinery Sales Ltd. For instance, a plastics manufacturing firm increased its output by 30% after implementing customized screw designs and advanced control systems provided by Extrusion Machinery Sales Ltd. Another example is a food processing company that reduced energy consumption by 25% through optimized extrusion processes designed by Extrusion Machinery Sales Ltd.

Industry Applications of Extrusion Machinery

Plastics Industry

In the plastics industry, extrusion machinery is used to produce a wide range of products such as pipes, profiles, and packaging materials. Extrusion Machinery Sales Ltd provides solutions tailored to specific plastic types and applications, ensuring high-quality products with consistent properties.

Metals Industry

In metal extrusion, machinery is used to shape metals into various forms like tubes, rods, and profiles. Extrusion Machinery Sales Ltd offers machinery designed for high-pressure metal extrusion, ensuring precise control over the forming process.

Food Processing

In food processing, extrusion is used to create products like breakfast cereals, snacks, and pet food. Extrusion Machinery Sales Ltd provides machinery that can handle a variety of food materials, ensuring consistent texture and quality in the final products.

Future Trends in Extrusion Technology

The future of extrusion technology is moving towards more sustainable and environmentally friendly processes. This includes the use of recycled materials, energy-efficient machinery, and processes that minimize waste. Extrusion Machinery Sales Ltd is at the forefront of these developments, offering solutions that not only enhance efficiency but also contribute to a more sustainable manufacturing environment.

Collaboration and Innovation

Extrusion Machinery Sales Ltd collaborates with research institutions and industry partners to innovate and improve extrusion technology. This collaborative approach ensures that their machinery incorporates the latest advancements in materials science and manufacturing processes, providing clients with cutting-edge solutions.

Conclusion

Extrusion Machinery Sales Ltd offers a comprehensive suite of solutions designed to enhance production efficiency across various industries. By leveraging advanced technology, customized designs, and expert support, manufacturers can optimize their extrusion processes, reduce waste, and improve product quality. Whether you are in plastics, metals, or another sector, Extrusion Machinery Sales Ltd is your partner for achieving operational excellence.

Frequently Asked Questions

1. What are the key components of an extrusion machine?

- The key components include the feed hopper, barrel and screw, die, heating and cooling systems, drive motor, and control systems.

2. How does automation improve extrusion efficiency?

- Automation enhances efficiency by controlling parameters like temperature, pressure, and speed, reducing manual errors and allowing for real-time monitoring.

3. What is the importance of customized screw and die designs?

- Customized designs improve melt quality and throughput by matching specific materials and applications, leading to higher-quality products.

4. Why is material selection crucial in extrusion?

- Material selection is crucial because it affects production speed, product quality, and compatibility with machinery, impacting overall efficiency.

5. What kind of support does Extrusion Machinery Sales Ltd offer?

- Extrusion Machinery Sales Ltd provides comprehensive after-sales support, including installation assistance, maintenance guidance, and ongoing technical support.