Content Menu

● Understanding Aluminum Extrusion

● What is an Aluminum Extrusion Drill Jig?

● Benefits of Using an Aluminum Extrusion Drill Jig

● How to Use an Aluminum Extrusion Drill Jig

● Applications of Aluminum Extrusion Drill Jigs

● Design Features of Aluminum Extrusion Drill Jigs

● Visualizing the Process

● Common Mistakes When Using Drill Jigs

● Enhancing Your Workflow with Technology

● Conclusion

● FAQ

>> 1. What is an aluminum extrusion drill jig?

>> 2. How does using a drill jig improve accuracy?

>> 3. Can anyone use an aluminum extrusion drill jig?

>> 4. What types of projects benefit from using a drill jig?

>> 5. Are there different types of jigs available for various applications?

● Citations:

In today's fast-paced manufacturing environment, efficiency and precision are paramount. One tool that has gained popularity for enhancing productivity in machining processes is the aluminum extrusion drill jig. This specialized device not only simplifies the drilling process but also significantly reduces the time and effort required to achieve accurate results. This article explores the various ways an aluminum extrusion drill jig can save you time and effort, while also providing insights into its design, functionality, and applications.

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves forcing aluminum through a shaped opening in a die to create specific profiles. This technique is widely used due to aluminum's unique properties, including its lightweight nature, corrosion resistance, and excellent strength-to-weight ratio. The versatility of aluminum extrusions makes them suitable for a variety of applications, from automotive components to architectural structures.

What is an Aluminum Extrusion Drill Jig?

An aluminum extrusion drill jig is a device designed to hold and guide the drill bit during the drilling process on aluminum extrusions. It ensures that holes are drilled at precise locations and angles, which is crucial for maintaining the integrity of the finished product. The jig typically features adjustable components that allow it to accommodate different sizes and shapes of extrusions.

Benefits of Using an Aluminum Extrusion Drill Jig

Increased Accuracy

One of the primary advantages of using an aluminum extrusion drill jig is the increased accuracy it provides. By guiding the drill bit precisely where it needs to go, jigs minimize the risk of misalignment or errors during drilling. This accuracy is especially important in high-volume production settings where consistency is key.

Time Efficiency

Using a drill jig can significantly reduce setup time. Traditional methods often require extensive measuring and marking before drilling can begin. With a drill jig, these steps are streamlined, allowing operators to quickly position the jig and start drilling. This efficiency translates into faster production times and reduced labor costs.

Reduced Operator Fatigue

Drilling without a jig can be physically demanding, especially when working with larger or heavier aluminum extrusions. A drill jig provides stability and support, allowing operators to work more comfortably and with less strain. This ergonomic advantage can lead to improved productivity as operators can maintain focus and energy throughout their shifts.

Minimized Material Waste

Precision drilling reduces the likelihood of mistakes that can result in wasted materials. By ensuring that each hole is drilled correctly on the first attempt, an aluminum extrusion drill jig helps manufacturers avoid costly rework or scrap.

How to Use an Aluminum Extrusion Drill Jig

Using an aluminum extrusion drill jig involves several straightforward steps:

1. Setup: Secure the aluminum extrusion in place on your workbench or machine table.

2. Positioning: Attach the drill jig to the extrusion, aligning it according to your project specifications.

3. Drilling: Insert the appropriate drill bit into your drill press or handheld drill, ensuring it fits snugly within the jig's guide.

4. Execution: Begin drilling at a slow speed to ensure accuracy, gradually increasing speed as needed.

5. Finishing: After drilling, remove the jig and inspect the holes for quality.

Applications of Aluminum Extrusion Drill Jigs

Aluminum extrusion drill jigs are versatile tools used across various industries:

- Automotive Manufacturing: Used for creating precise holes in chassis components.

- Construction: Essential for drilling holes in extruded aluminum frames for windows and doors.

- Furniture Production: Helps in assembling modular furniture with precision-drilled connections.

- Custom Projects: Ideal for hobbyists and DIY enthusiasts working on custom builds involving aluminum extrusions.

Design Features of Aluminum Extrusion Drill Jigs

The design of an aluminum extrusion drill jig plays a crucial role in its effectiveness. Here are some key features:

- Adjustable Clamps: These allow users to secure different sizes of extrusions firmly in place without damaging them.

- Guide Bushings: These components help maintain alignment during drilling, ensuring that each hole is perfectly positioned.

- Material Quality: Most jigs are made from durable materials such as steel or high-grade plastics that withstand wear over time.

- Portability: Many jigs are designed to be lightweight and portable, making them easy to transport between job sites.

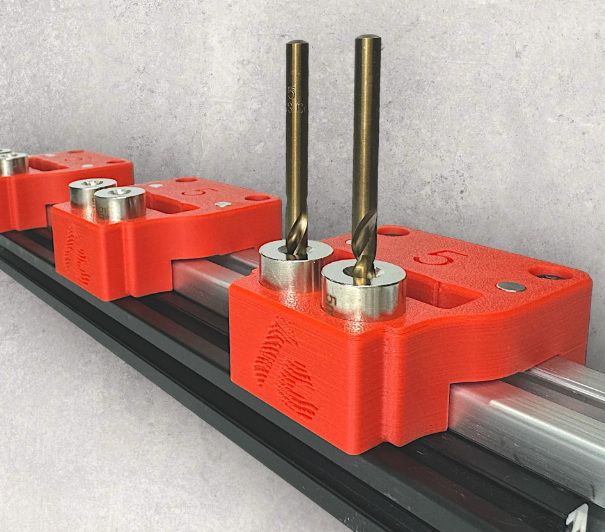

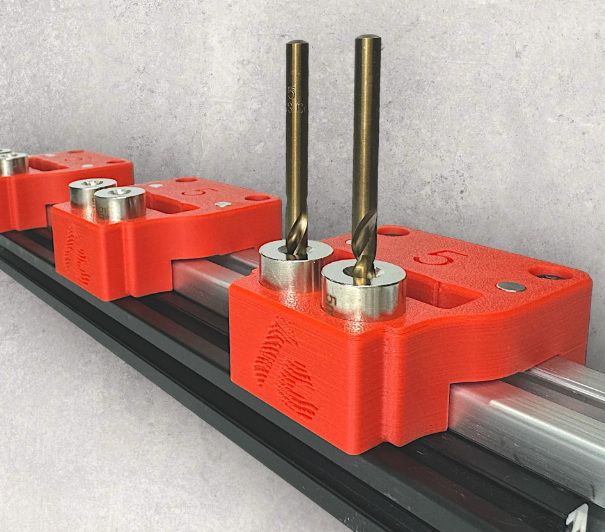

Visualizing the Process

To better illustrate how an aluminum extrusion drill jig works, consider including images or videos demonstrating:

- The setup process of securing an aluminum extrusion.

- A step-by-step guide on using a drill jig.

- Examples of finished products that utilize drilled extrusions.

Common Mistakes When Using Drill Jigs

While using an aluminum extrusion drill jig can greatly enhance efficiency, there are common mistakes that users should avoid:

- Incorrect Alignment: Failing to align the jig properly can lead to misdrilled holes, which may compromise structural integrity.

- Using Wrong Drill Bits: Selecting inappropriate bits for specific tasks can cause damage to both the material and the tool.

- Neglecting Maintenance: Regularly checking and maintaining jigs ensures they function correctly over time.

Enhancing Your Workflow with Technology

Incorporating technology alongside traditional tools can further enhance productivity when using an aluminum extrusion drill jig:

- CAD Software: Utilizing computer-aided design (CAD) software allows for precise planning before physical work begins, reducing errors during setup.

- Digital Measuring Tools: These tools provide accurate measurements quickly, ensuring that setups are correct before drilling starts.

- Automated Drilling Machines: For high-volume production environments, automated machines equipped with jigs can significantly increase output while maintaining precision.

Conclusion

The use of an aluminum extrusion drill jig can dramatically enhance productivity by saving time and reducing effort in machining processes. Its ability to provide accuracy, minimize waste, and reduce operator fatigue makes it an invaluable tool in both industrial settings and DIY projects. As manufacturers continue to seek ways to optimize their operations, investing in quality jigs will likely remain a key strategy for success.

FAQ

1. What is an aluminum extrusion drill jig?

An aluminum extrusion drill jig is a specialized tool used to guide drills accurately when creating holes in aluminum extrusions.

2. How does using a drill jig improve accuracy?

A drill jig ensures that drills are positioned correctly every time, reducing errors associated with manual measuring and marking.

3. Can anyone use an aluminum extrusion drill jig?

Yes, they are designed for ease of use, making them suitable for both skilled professionals and DIY enthusiasts.

4. What types of projects benefit from using a drill jig?

Projects across automotive manufacturing, construction, furniture production, and custom builds all benefit from using a drill jig.

5. Are there different types of jigs available for various applications?

Yes, there are many types of jigs tailored for specific applications depending on size, shape, and complexity of the task at hand.

Citations:

[1] https://kimsen.vn/jigs-and-fixtures-%E2%80%93-all-you-need-to-know-ne73.html

[2] https://tri-stateal.com/blog/aluminum-extrusions-guide/

[3] https://www.reidsupply.com/en-us/industry-news/what-are-jigs-and-fixtures

[4] https://www.youtube.com/watch?v=GnDETVSIw-0

[5] https://my.misumi-ec.com/vona2/detail/110302268730/

[6] https://www.youtube.com/watch?v=AG8ZcRiwBio

[7] https://blog.airlinehyd.com/how-to-build-anything-with-aluminum-extrusion-in-3-steps

[8] https://toolstoday.com/learn/the-benefits-of-using-high-speed-drill-bits-in-your-projects

[9] https://www.alumforge.com/ba/product/aluminum-extrusion-drill-jig/