Content Menu

● Understanding Aluminum Extrusion

● The Role of Hydraulic Presses in Reducing Waste

● Innovations Driving Waste Reduction

● Benefits of Reducing Material Waste

● Applications Across Industries

● Environmental Sustainability Through Aluminum Extrusion

● Future Trends in Aluminum Extrusion

● Conclusion

● FAQs

>> 1. What is aluminum extrusion?

>> 2. How does reducing waste benefit manufacturers?

>> 3. What technologies are used in modern aluminum extrusion?

>> 4. Can scrap aluminum be reused in the extrusion process?

>> 5. What industries benefit from aluminum extrusion?

● Citations:

Aluminum extrusion is a highly efficient manufacturing process that shapes aluminum alloys into desired profiles by forcing them through a die using a hydraulic press. This method not only produces lightweight and durable components but also plays a crucial role in minimizing material waste. In this article, we will explore how aluminum extrusion hydraulic presses contribute to waste reduction, the processes involved, and the benefits of adopting this technology in various industries.

Understanding Aluminum Extrusion

Aluminum extrusion involves several key steps:

1. Billet Preparation: Aluminum billets are preheated to make them malleable. This heating process is critical as it affects the efficiency of the extrusion and the quality of the final product.

2. Extrusion Process: The heated billet is placed into a hydraulic press, where a ram applies immense pressure (up to 15,000 tons) to push the aluminum through a die. The shape of the die determines the profile of the extruded aluminum.

3. Cooling and Handling: After exiting the die, the extruded aluminum is rapidly cooled (quenched) to solidify its shape before being cut to specified lengths.

4. Post-Processing: The extrusions may undergo further treatments such as aging, machining, or surface finishing to meet specific requirements.

The Role of Hydraulic Presses in Reducing Waste

Hydraulic presses are central to the aluminum extrusion process and significantly contribute to waste reduction in several ways:

1. Optimized Material Usage

Hydraulic presses allow for precise control over the extrusion process, enabling manufacturers to optimize billet sizes according to production needs. By closely matching the size of the billet to the required output, manufacturers can minimize excess material that would otherwise go to waste.

2. Reduced Scrap Generation

The design of hydraulic presses facilitates efficient material flow through the die, leading to fewer defects and less scrap material. Advanced die designs and improved cooling techniques ensure that extruded profiles maintain their integrity, further reducing scrap rates during production.

3. Enhanced Yield Rates

Modern hydraulic presses are equipped with advanced technology that allows for real-time monitoring and adjustments during the extrusion process. This capability helps maintain optimal conditions for each extrusion cycle, resulting in higher yield rates and less wasted material.

4. Recycling Capabilities

Any scrap generated during the extrusion process can be recycled back into production. Hydraulic presses can handle recycled aluminum efficiently, allowing manufacturers to reintroduce scrap into the process without significant loss of quality.

Innovations Driving Waste Reduction

Recent advancements in technology have further enhanced the efficiency of aluminum extrusion processes:

1. Automation and Robotics

The integration of automation and robotics in extrusion plants streamlines operations and reduces human error. Automated systems can manage tasks such as loading billets, handling extrusions, and performing quality checks, which minimizes waste caused by manual handling errors.

2. Advanced Die Design

Innovations in die design allow for more complex shapes while maintaining material efficiency. Computer-aided design (CAD) software enables engineers to create intricate dies that optimize material flow and reduce waste during production.

3. Energy-Efficient Processes

Energy-efficient heating methods, such as induction heating, reduce energy consumption during billet preparation while ensuring uniform heating. This not only lowers operational costs but also contributes to sustainability by minimizing energy waste.

Benefits of Reducing Material Waste

Reducing material waste in aluminum extrusion processes offers numerous benefits:

- Cost Savings: Lowering scrap rates directly translates to reduced material costs for manufacturers.

- Environmental Impact: Minimizing waste contributes to sustainability efforts by reducing landfill contributions and conserving resources.

- Improved Product Quality: Efficient processes lead to higher-quality products with fewer defects, enhancing customer satisfaction.

Applications Across Industries

Aluminum extrusion is utilized in various sectors, showcasing its versatility and adaptability:

- Construction: Used for window frames, curtain walls, and structural components due to their strength and resistance to corrosion.

- Automotive: The automotive industry employs aluminum extrusions for lightweight components, improving fuel efficiency and performance.

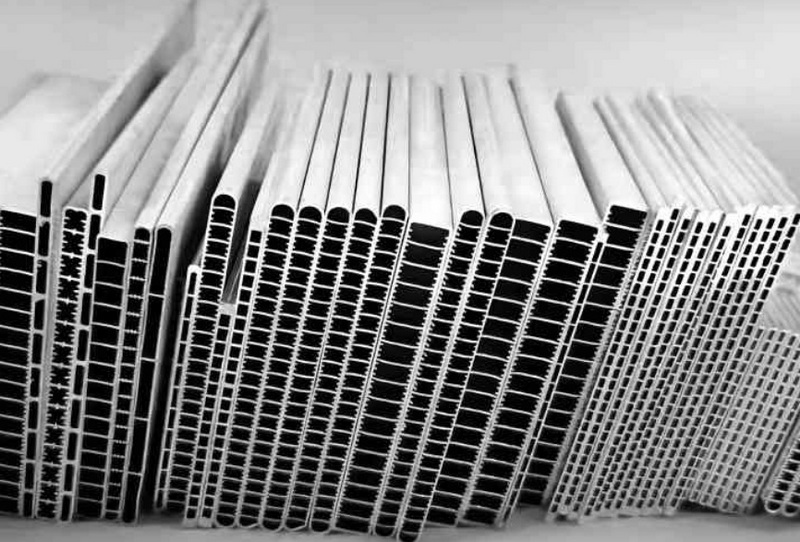

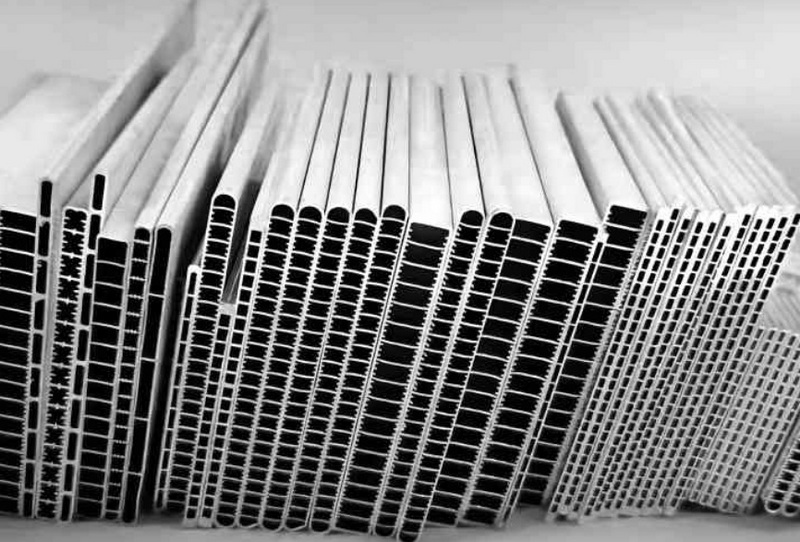

- Electronics: Aluminum extrusions are used in manufacturing heat sinks, enclosures, and other electronic components benefiting from aluminum's thermal conductivity.

- Aerospace: The aerospace industry relies on aluminum extrusions for structural components where weight reduction is critical for performance.

Environmental Sustainability Through Aluminum Extrusion

Aluminum extrusion is increasingly recognized for its potential environmental benefits:

- Recyclability: Aluminum can be recycled indefinitely without losing its properties. This characteristic supports sustainable manufacturing practices by reducing dependence on raw materials.

- Energy Efficiency: The energy required for recycling aluminum is significantly lower than that needed for primary production—approximately 95% less energy is consumed when recycling compared to producing new aluminum from ore.

- Closed-loop Systems: Many modern extrusion facilities implement closed-loop recycling systems that reclaim scrap aluminum produced during manufacturing processes, further minimizing waste.

Future Trends in Aluminum Extrusion

The future of aluminum extrusion looks promising with ongoing innovations aimed at enhancing efficiency and sustainability:

- Smart Manufacturing Technologies: The adoption of Industry 4.0 technologies—such as IoT (Internet of Things) devices—enables real-time monitoring of production processes. These technologies can predict maintenance needs before failures occur, thereby reducing downtime and improving overall productivity.

- Hybrid Systems: New hybrid systems combining hydraulic presses with servo technologies are emerging. These systems offer improved energy efficiency and precision control over the extrusion process while maintaining high production rates.

- Advanced Alloys: Ongoing research into new aluminum alloys enhances performance characteristics such as strength-to-weight ratios and corrosion resistance, making them suitable for even more demanding applications across various industries.

Conclusion

Aluminum extrusion hydraulic presses play a vital role in reducing material waste through optimized processes, advanced technology, and efficient recycling methods. As industries continue to prioritize sustainability and cost-effectiveness, adopting these practices will be crucial for meeting both economic and environmental goals.

FAQs

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy by forcing it through a die with a specific cross-sectional profile using high pressure from a hydraulic press.

2. How does reducing waste benefit manufacturers?

Reducing waste lowers material costs, enhances product quality, and minimizes environmental impact by conserving resources and reducing landfill contributions.

3. What technologies are used in modern aluminum extrusion?

Modern technologies include automation systems for handling materials, advanced die designs created with CAD software, and energy-efficient heating methods like induction heating.

4. Can scrap aluminum be reused in the extrusion process?

Yes, any scrap generated during production can be recycled back into the process without significant loss of quality.

5. What industries benefit from aluminum extrusion?

Industries such as construction, automotive, aerospace, and electronics utilize aluminum extrusion for its lightweight yet strong properties.

Citations:

[1] https://www.yjing-extrusion.com/what-are-the-key-benefits-of-using-an-aluminum-extrusion-press-in-manufacturing.html

[2] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[3] https://www.powermotiontech.com/hydraulics/hydraulic-valves/article/21263257/bosch-rexroth-extrusion-press-hydraulic-valve-controls-the-right-time-to-upgrade

[4] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[5] https://www.nicerapid.com/project/the-impact-of-aluminum-extrusion-process-on-the-environment/

[6] https://www.lightmetalage.com/news/industry-news/extrusion/upgrading-extrusion-press-hydraulics-and-controls-to-the-connected-future/

[7] https://www.powermotiontech.com/applications/machine-tools/article/21884588/hydraulic-upgrade-brings-new-life-to-extrusion-press

[8] https://www.retop-industry.com/news/aluminum-profile.html

[9] https://www.aluminiumalca.com/blog/exploring-the-advantages-and-applications-of-aluminum-extrusion/1/

[10] http://scaluminum.com/2017/08/the-sustainable-benefits-of-todays-custom-aluminum-extrusions/

[11] https://inquivixtech.com/aluminum-extrusion-process/

[12] https://taberextrusions.com/environmental-advantages-of-aluminum-extrusions/

[13] https://www.techbriefs.com/component/content/article/45505-improving-extrusion-press-performance-with-hydraulics-upgrade

[14] https://cdn.ymaws.com/members.aec.org/resource/resmgr/PDFs/BackgrounderAlExt.pdf

[15] https://www.keymarkcorp.com/environment-statement/

[16] https://www.powermotiontech.com/learning-resources/white-papers/whitepaper/55022096/modernization-of-aluminum-extrusion-press-raises-productivity-saves-energy

[17] https://hitopindustrial.com/aluminum-extrusion-process/

[18] https://p2infohouse.org/ref/19/18199.htm

[19] https://www.danieli.com/en/news-media/news/danieli-presses-selected-extrude-products-demanding-applications_37_703.htm

[20] https://aec.org/aluminum-extrusion-process

[21] https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=30003V54.TXT

[22] https://extal.com/en/the-evolution-of-aluminum-extrusion-techniques-with-extal/

[23] https://www.ubemachinery.com/news/documents/sshybridextrusion.pdf

[24] https://www.danieli.com/en/news-media/news/new-danieli-40-mn-front-loading-extrusion-press-cansan-aluminium_37_643.htm